Method for measuring polymer weight-average molecular weight

A weight-average molecular weight and polymer technology, which is applied in the direction of measuring devices, testing material strength by using one-time impact force, and analyzing materials, can solve the problems of polymer molecular weight difficulties, and overcome the inability or difficulty to measure insoluble or insoluble substances. Effect of Weight Average Molecular Weight Limitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

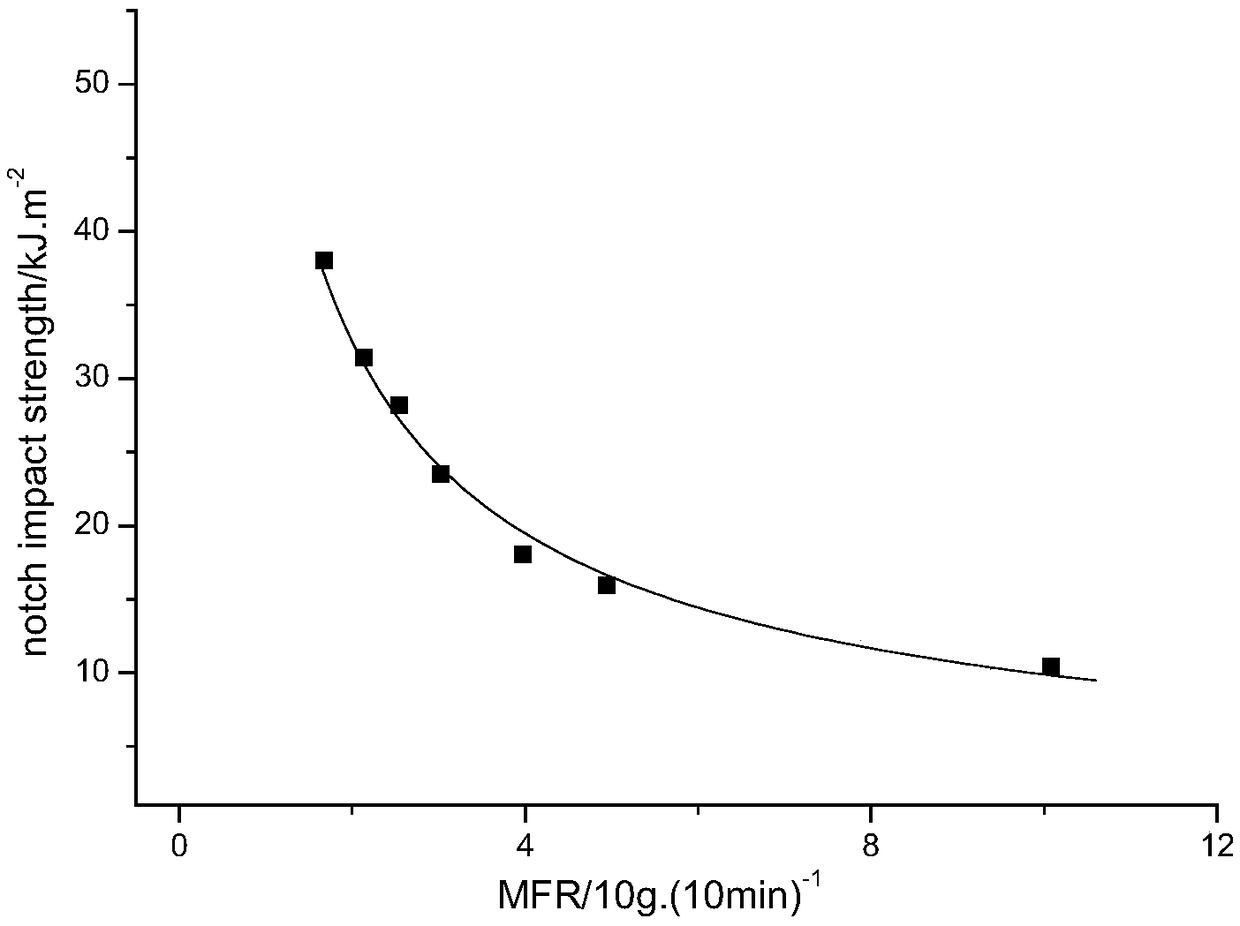

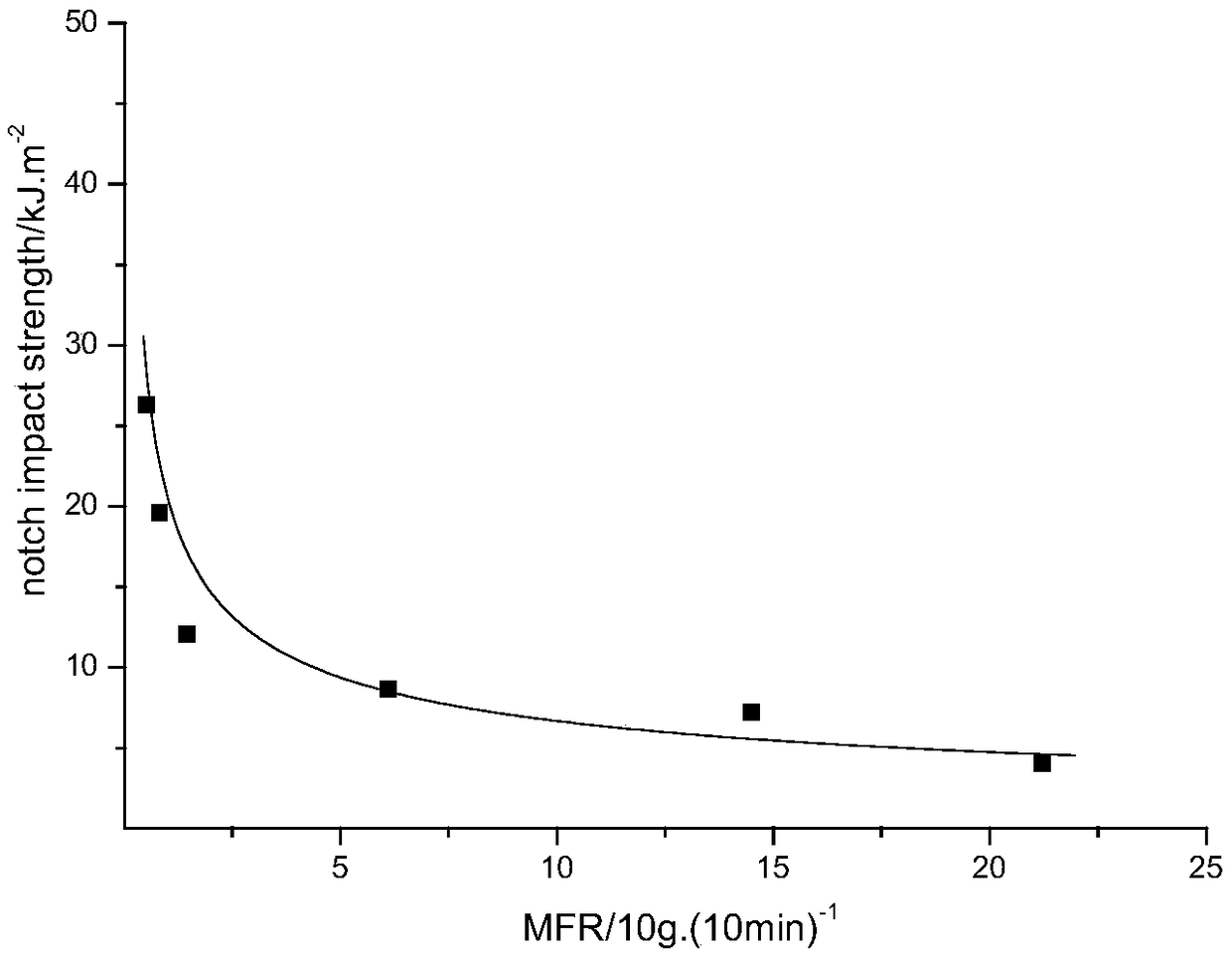

[0030] The first step is to measure the notched impact strength z of the polymer sample on the impact testing machine; (standard is GB / T 1843-2008)

[0031] In the second step, the melt flow rate x of the polymer sample is measured on a melt flow rate meter; (the standard is GB / T3682-2000).

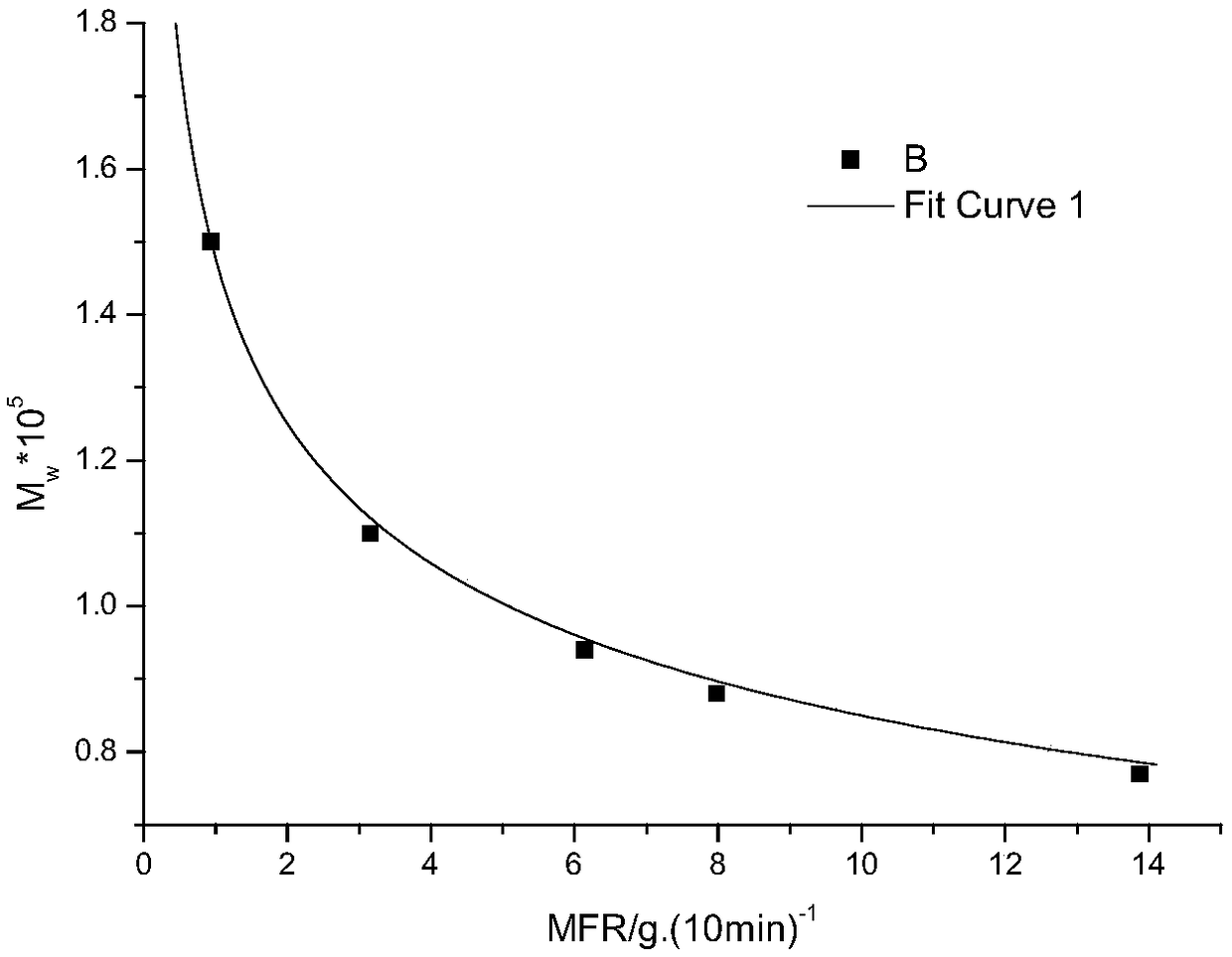

[0032] According to the above steps, the weight average molecular weight M (M A ,M B ,M C ,M D ) and melt flow rate x(x A , x B , x C , x D ) (190°C, 2.16kg) data, make the fitting curve of the weight average molecular weight M changing with the melt flow rate x, the relationship curve is as follows figure 1 shown;

[0033] from figure 1 It can be seen that the relationship between the two can be used M=10 5 ×D0×x D Formula (II) expresses,

[0034] where D=-0.24, D0=1.477.

[0035] Thus it can be known that the weight average molecular weight M of the high-density polyethylene sample A A vs. melt flow rate x A (190°C, 2.16kg);

[0036] Take two polymer materials such as HD...

Embodiment 2

[0046] The first step is to measure the notched impact strength z of the polymer sample on the impact testing machine; (the measurement standard is GB / T1843-2008)

[0047] The second step is to measure the melt flow rate x of the polymer sample on a melt flow rate meter; (measurement standard is GB / T3682-2000).

[0048] According to the above steps, the weight average molecular weight M (M A ,M B ,M C ,M D ) and melt flow rate x(x A , x B , x C , x D ) (190°C, 2.16kg) data, make the fitting curve of the weight average molecular weight M changing with the melt flow rate x, the relationship curve is as follows figure 1 shown;

[0049] from figure 1 It can be seen that the relationship between the two can be used M=10 5 ×D0×x D (II) said,

[0050] where D=-0.24, D0=1.477.

[0051] Thereby it can be known that the weight-average molecular weight M of the high-density polyethylene sample B B vs. melt flow rate x B (190°C, 2.16kg);

[0052] Take two polymer materials...

Embodiment 3

[0062] The first step is to measure the notched impact strength z of the polymer sample on the impact testing machine; (the measurement standard is GB / T1843-2008)

[0063] The second step is to measure the melt flow rate x of the polymer sample on the melt flow rate meter; (measurement standard is GB / T3682-2000);

[0064] According to the above steps, the weight average molecular weight M (M A ,M B ,M C ,M D ) and melt flow rate x(x A , x B , x C , x D ) (190°C, 2.16kg) data, make the fitting curve of the weight average molecular weight M changing with the melt flow rate x, the relationship curve is as follows figure 1 shown;

[0065] from figure 1 It can be seen that the relationship between the two can be used M=10 5 ×D0×x D (II) said,

[0066] where D=-0.24, D0=1.477.

[0067] from figure 1 The weight-average molecular weight M of the high-density polyethylene sample C C vs. melt flow rate x C (190℃, 2.16kg)

[0068] Relationship;

[0069] Choose HDPE C an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com