Process cartridge regeneration method and regenerative process cartridge

A technology for processing boxes and waste toner bins, applied in electrography, optics, instruments, etc., which can solve problems such as waste, environmental pollution, and the inability of the drum 631 to receive transmission force, so as to facilitate regeneration, ensure printing quality, and regenerate Simple process and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

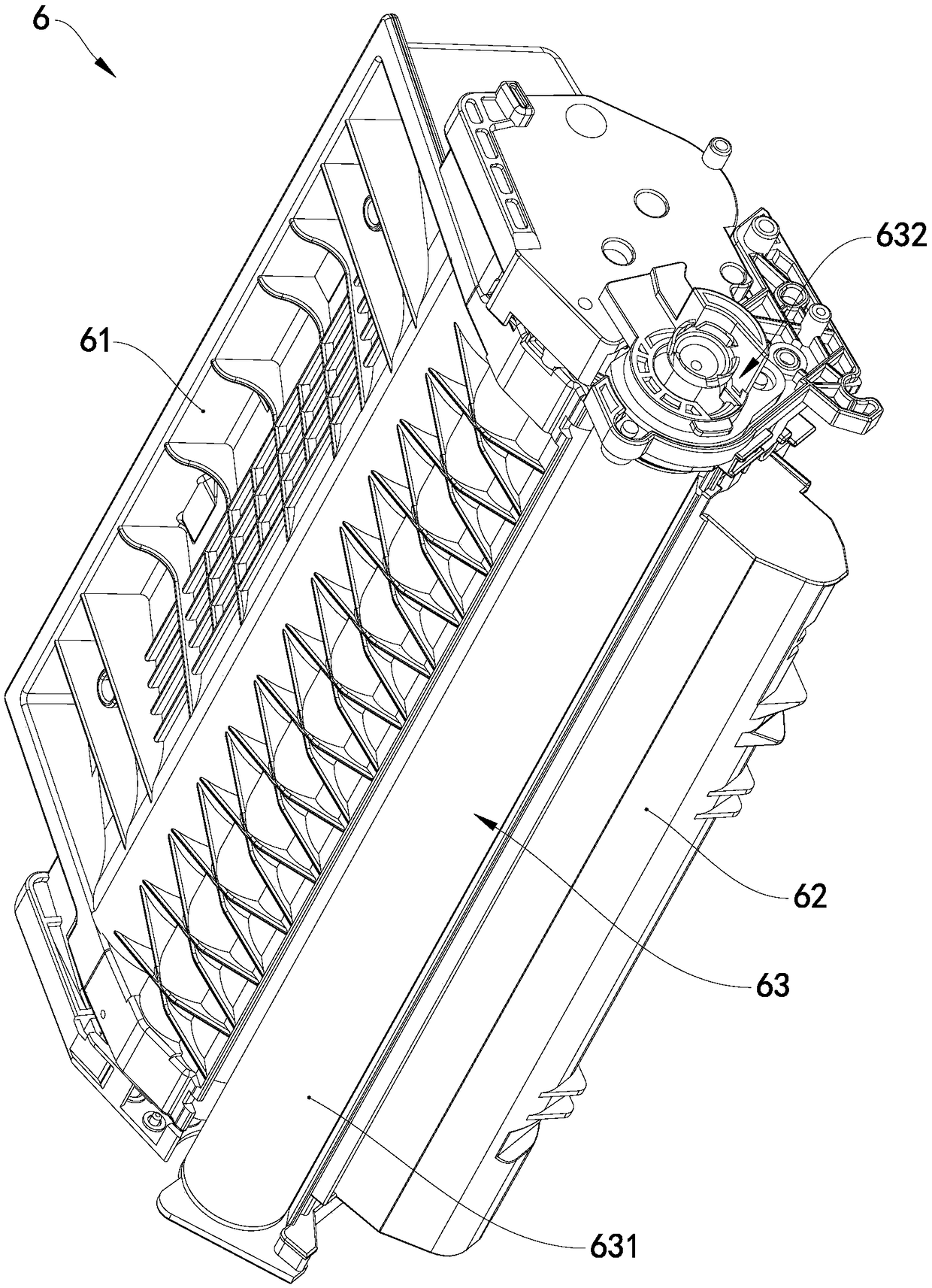

[0040] see Figure 5 , the regenerating method of the toner cartridge is composed of a dismantling step, a cutting step, a cleaning step, a refitting step and an assembling step.

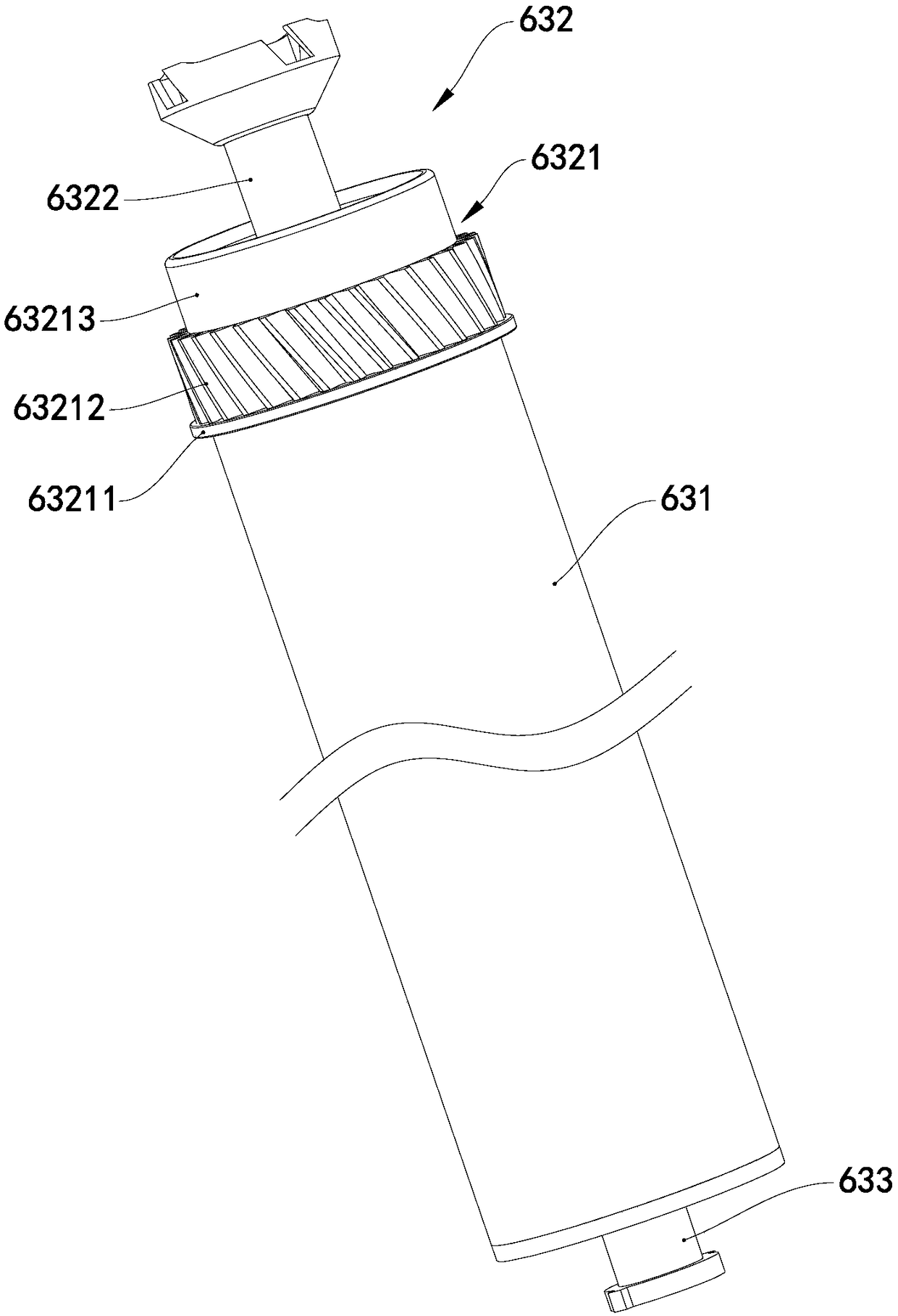

[0041] Disassembly steps: remove the connecting pins between the powder bin 61 and the waste toner bin 62, remove the powder outlet knife, magnetic roller and end cover from the powder bin 61, remove the photosensitive drum 63, the cleaning scraper and the charging roller.

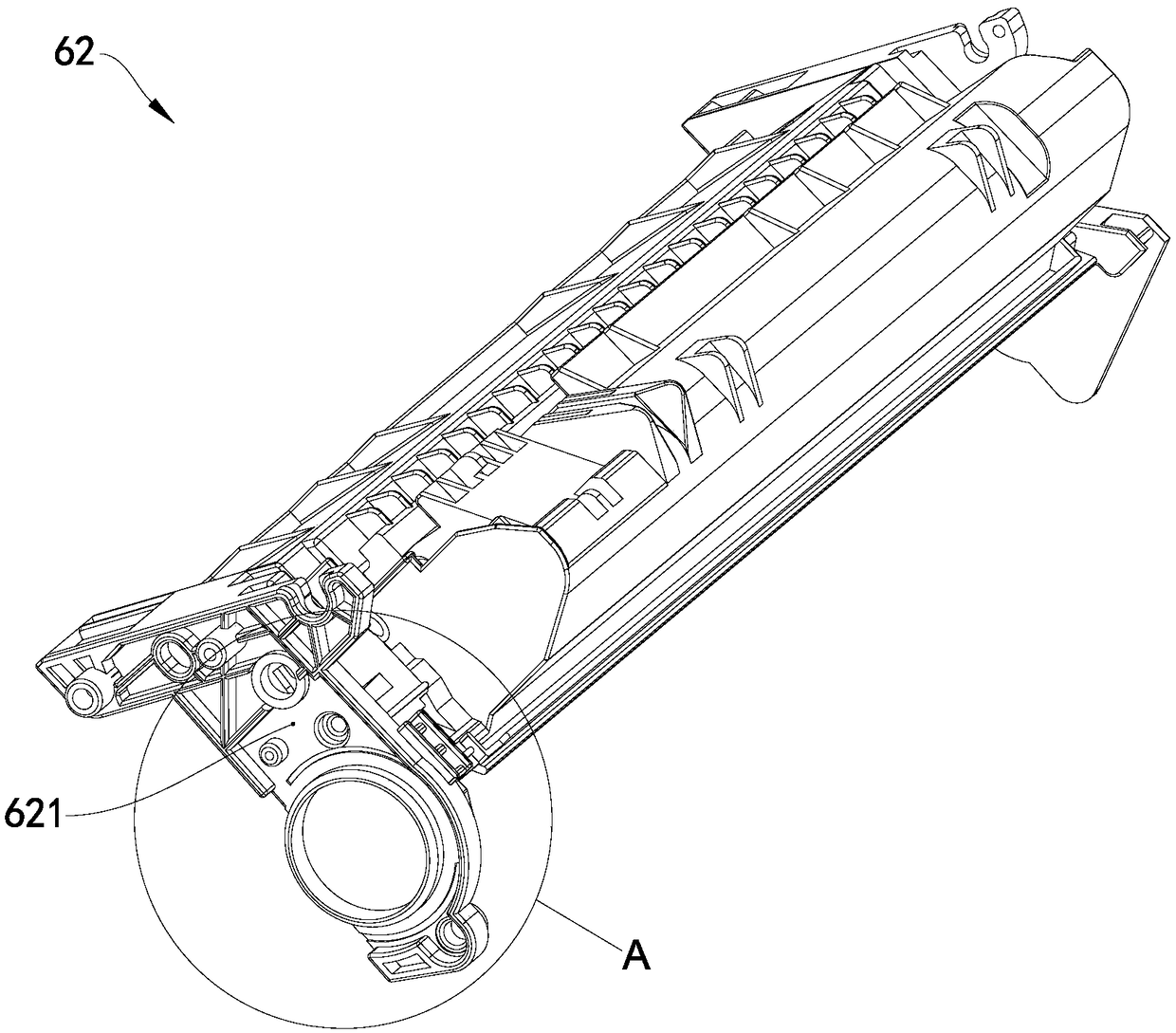

[0042] Cutting step: cut an opening 625 of the waste toner bin 62 at the same position in the axial direction of the supporting ring part 622 and the protruding ring part 623, cut the first slot 626 on the protruding ring part 623, and cut the reinforcing rib part 627 Out of the second slot 627. The waste toner bin 62 after the cutting step is as Figure 7 with 8 shown.

[0043] Cleaning step: cleaning the parts except the drum 631 and the rotational force transmission assembly 632 removed in the dismantling step and the wa...

no. 2 example

[0058] As a description of the second embodiment of the process cartridge reproducing method of the present invention, only the differences from the first embodiment of the process cartridge reproducing method will be described below.

[0059] see Figure 17 , The regeneration method of the process cartridge in this embodiment is composed of a disassembly step, a cleaning step, a refitting step and an assembly step. Wherein the disassembly steps are the same as the first embodiment of the regeneration method of the above-mentioned process cartridge, and only the different cleaning steps, refitting steps and assembling steps will be described below.

[0060] The cleaning step is to clean the parts removed in the dismantling step except the waste toner bin, the drum and the rotating force transmission assembly.

[0061] The refitting procedure is to use a structure that is the same as that of the dismantled waste powder bin, but the supporting ring part and the protruding ring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com