A Vacuum Mounting Process for Samples After Irradiation

An inlay process and vacuum technology, applied in the field of nuclear fuel irradiation detection, can solve unreliable, inaccurate inspection results of rod-shaped fuel elements, the inner surface of the fuel cladding, the outer surface of the fuel core and the crack shape are not effectively protected. and other problems to achieve the effect of improving the accuracy and evaluating the irradiation performance accurately.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

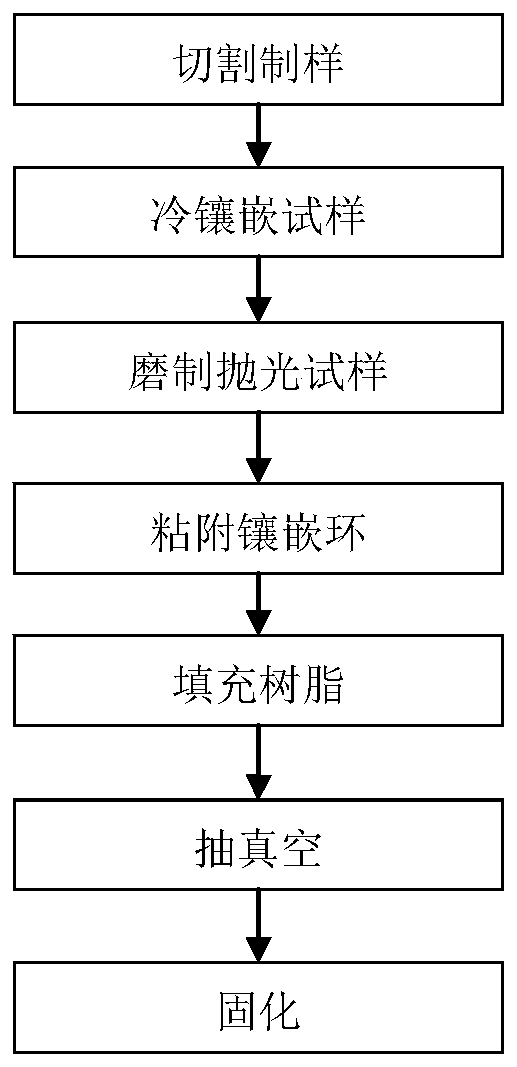

[0044] Such as figure 1 A vacuum mosaic process for a sample after irradiation is shown, comprising the following steps:

[0045] (A) Cutting sample preparation, selecting fuel elements at characteristic positions, cutting and preparing samples, the height of the prepared samples is 20mm;

[0046] (B) Cold mounting the sample, put the sample into the mounting tube with an outer diameter of 25 mm in the hot chamber, and then fill the mounting tube with epoxy resin for cold mounting, and the filling height of the epoxy resin is 20 mm;

[0047] (C) Grinding and polishing the sample, using a hot chamber polishing machine, grinding the sample on a 220 mesh, 600 mesh and 1200 mesh diamond grinding disc in turn, and then using diamond suspensions with a particle size of 9 μm, 3 μm and 1 μm in sequence. The sample is polished, and finally the gap between the cladding and the core block in the sample and / or the cracks on the core block are exposed on the polished surface of the sample...

Embodiment 2

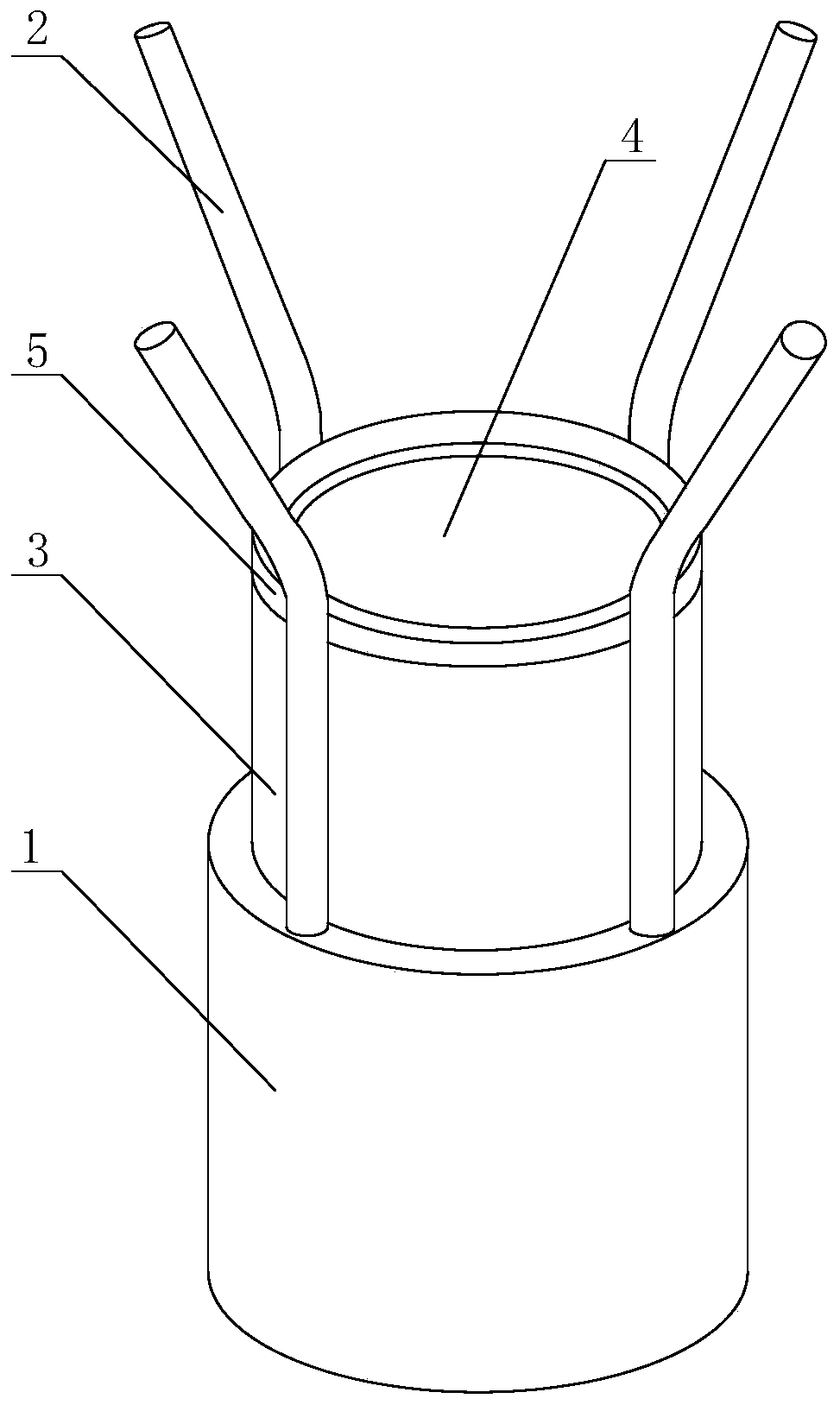

[0053] Such as figure 2 As shown, on the basis of Embodiment 1, an inlaid ring installation device is designed to install the inlaid ring with a manipulator in the hot chamber. Specifically, the sample is placed in the inlay ring installation device to install the inlay ring 5. The inlay ring installation device includes a fixed cylinder 1 for placing the sample 4, and four guide rods 2 are arranged on the top surface of the fixed cylinder 1. , four guide rods 2 are evenly arranged along the circumference of the fixed cylinder 1; the guide rods 2 are bent to the outside of the fixed cylinder 1, and the position of the bending point of the guide rods 2 is configured such that the sample 4 is located in the fixed cylinder 1, and When the bottom surface of the sample 4 is flush with the bottom surface of the fixed cylinder 1, the bending point of the guide rod 2 is located above the sample 4; The outer diameter; the height of the mosaic ring 5 is 1-2 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com