Control method for casting blank surface cracks caused by proeutectoid ferrites

A pro-eutectoid ferrite and control method technology, applied in the field of metallurgy, can solve problems such as limiting steelmaking and steel rolling connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

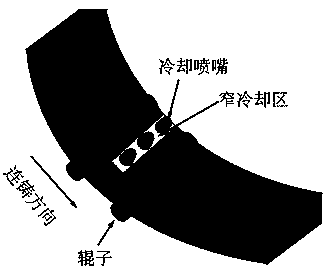

[0017] First, the infrared thermometer is used to continuously measure the surface temperature of the slab from the crystallizer to the straightening section, and then the point where the surface temperature of the slab experiences 800°C for the first time is selected as the starting point of enhanced cooling in this method; After the slab temperature range, a row of cooling water nozzles with a cooling width of 10mm is installed in this area, the cooling water flow rate is 1 L / min, and the cooling water pressure is 0.4MPa to forcefully cool the surface of the slab without affecting the internal temperature of the slab . In addition to adding a row of nozzles to the continuous casting machine, other process parameters of the continuous casting machine remain unchanged.

Embodiment 2

[0019] First, the infrared thermometer is used to continuously measure the surface temperature of the slab from the crystallizer to the straightening section, and then the point where the surface temperature of the slab experiences 800°C for the first time is selected as the starting point of enhanced cooling in this method; After the slab temperature range, a row of cooling water nozzles with a cooling width of 30mm is installed in this area, the cooling water flow rate is 1 L / min, and the cooling water pressure is 0.4MPa to forcefully cool the surface of the slab without affecting the internal temperature of the slab . In addition to adding a row of nozzles to the continuous casting machine, other process parameters of the continuous casting machine remain unchanged.

Embodiment 3

[0021] First, the infrared thermometer is used to continuously measure the surface temperature of the slab from the crystallizer to the straightening section, and then the point where the surface temperature of the slab experiences 800°C for the first time is selected as the starting point of enhanced cooling in this method; After the slab temperature range, a row of cooling water nozzles with a cooling width of 10mm is installed in this area, the cooling water flow rate is 3 L / min, and the cooling water pressure is 0.4MPa to forcefully cool the surface of the slab without affecting the internal temperature of the slab . In addition to adding a row of nozzles to the continuous casting machine, other process parameters of the continuous casting machine remain unchanged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com