Crack self-healing ceramic tool material and preparation method thereof

A self-healing technology for ceramic knives, applied in the field of ceramic knives materials, to achieve the effect of improving mechanical properties, improving service life and safety, and shortening the cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

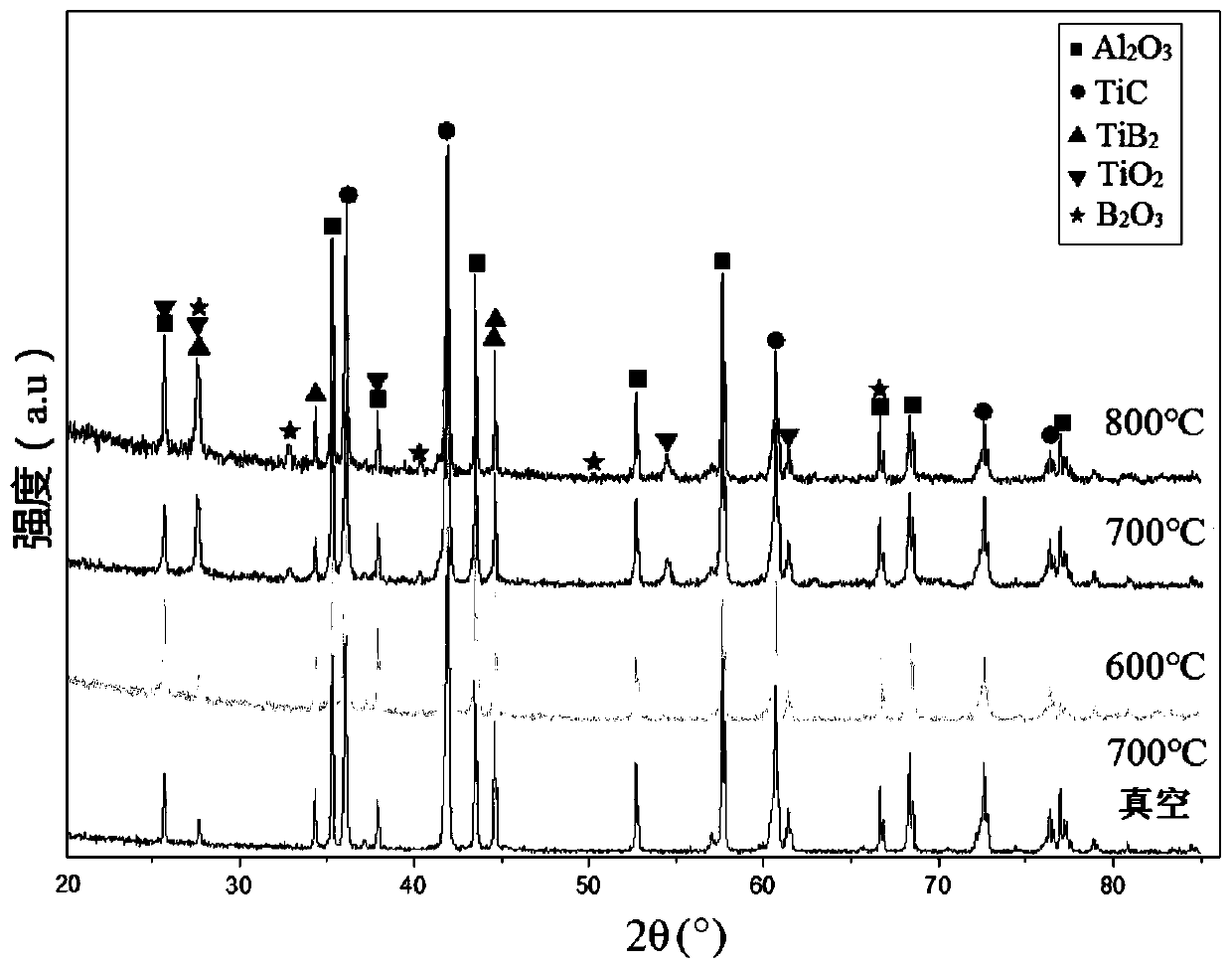

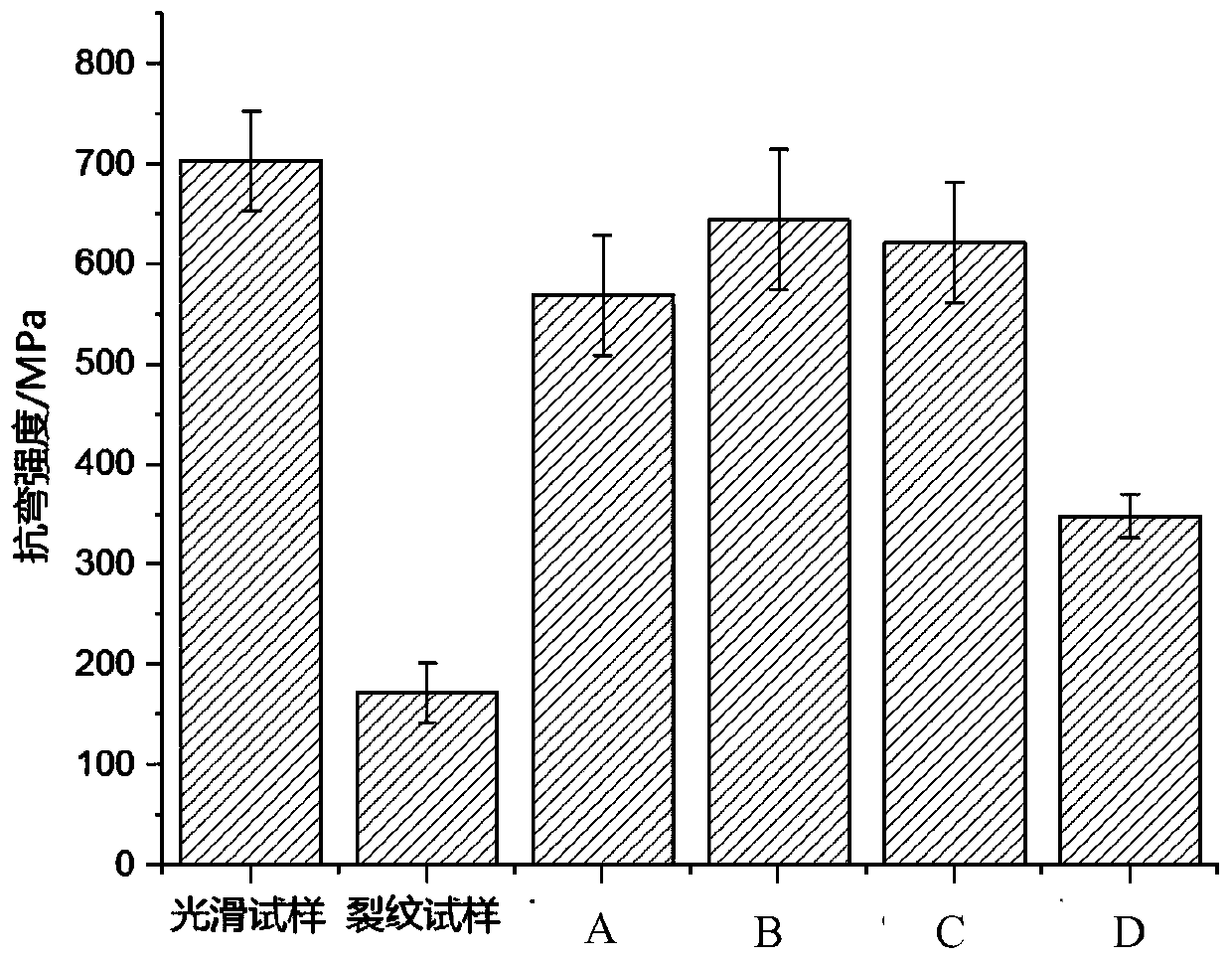

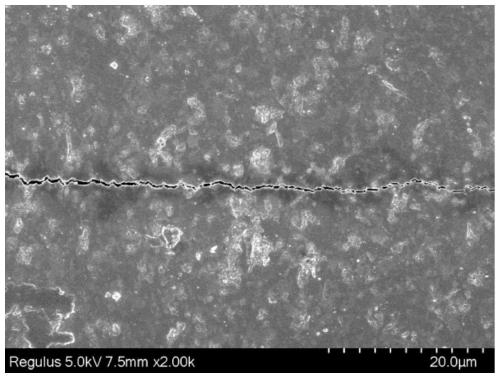

[0042] A crack self-healing ceramic tool material, raw material composition volume percentage: α-Al 2 o 3 62.65 parts, TiC26.85 parts, TiB 2 10 parts, MgO 0.5 parts.

[0043] Weigh TiB in proportion 2 Powder, take polyethylene glycol (PEG4000) with a molecular weight of 4000 as a dispersant, add an appropriate amount of absolute ethanol, ultrasonically disperse and mechanically stir for 20-30min, and make TiB 2 Suspension; then weigh α-Al in proportion 2 o 3 and TiC powder, add an appropriate amount of absolute ethanol as the dispersion medium, ultrasonically disperse and mechanically stir for 20-30min, and make α-Al 2 o 3 Suspension and TiC suspension; mix the above three suspensions to obtain a multi-phase suspension, then add MgO powder in proportion, ultrasonically disperse and mechanically stir for 30 minutes; pour the resulting final suspension into a ball mill tank, and Add cemented carbide balls at a ratio of 10:1, and conduct ball milling with nitrogen as a p...

Embodiment 2

[0046] A crack self-healing ceramic tool material, raw material composition volume percentage: α-Al 2 o 3 59.15 parts, TiC25.35 parts, TiB 2 15 parts, MgO 0.5 parts.

[0047] Weigh TiB in proportion 2 Powder, take polyethylene glycol (PEG4000) with a molecular weight of 4000 as a dispersant, add an appropriate amount of absolute ethanol, ultrasonically disperse and mechanically stir for 20-30min, and make TiB 2 Suspension; then weigh α-Al in proportion 2 o 3 and TiC powder, add an appropriate amount of absolute ethanol as the dispersion medium, ultrasonically disperse and mechanically stir for 20-30min, and make α-Al 2 o 3 Suspension and TiC suspension; mix the above three suspensions to obtain a multi-phase suspension, then add MgO powder in proportion, ultrasonically disperse and mechanically stir for 40 minutes; pour the resulting final suspension into a ball mill tank, and Add cemented carbide balls at a ratio of 15:1, and conduct ball milling with nitrogen as a p...

Embodiment 3

[0050] A crack self-healing ceramic tool material, raw material composition volume percentage: α-Al 2 o 3 62.65 parts, TiC26.85 parts, TiB 2 10 parts, MgO 0.5 parts.

[0051] Weigh TiB in proportion 2 Powder, take polyethylene glycol (PEG4000) with a molecular weight of 4000 as a dispersant, add an appropriate amount of absolute ethanol, ultrasonically disperse and mechanically stir for 20-30min, and make TiB 2 Suspension; then weigh α-Al in proportion 2 o 3 and TiC powder, add an appropriate amount of absolute ethanol as the dispersion medium, ultrasonically disperse and mechanically stir for 20-30min, and make α-Al 2 o 3 Suspension and TiC suspension; mix the above three suspensions to obtain a multi-phase suspension, then add MgO powder in proportion, ultrasonically disperse and mechanically stir for 30 minutes; pour the resulting final suspension into a ball mill tank, and Add cemented carbide balls at a ratio of 10:1, and conduct ball milling with nitrogen as a p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com