A kind of ceramic with multivariate high entropy and its preparation method and application

A multi-element high-entropy, ceramic technology, applied in the field of surface functional film materials, to achieve the effect of improving performance, improving sintering performance, and fast diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1. With HfO 2 , ZrO 2 , Nb 2 o 5 、 Ta 2 o 5 and Cr 2 o 3 And amorphous boron powder as raw material, with ethanol as solvent, with Si 3 N 4 The ball is the ball milling medium, mixed on the ball mill, and the mixed powder is obtained after drying;

[0032] 2. Put the green body obtained after the mixed powder is molded into a graphite crucible, raise the temperature to 1200°C at a rate of 10°C / min and keep it for 1h, then raise the temperature to 1600°C at a rate of 10°C / min and keep it for 1h, after vacuum heat treatment The acquisition (Hf 0.2 Zr 0.2 Nb 0.2 Ta 0.2 Cr 0.2 )B 2Ultrafine high-entropy ceramic solid solution powder.

[0033] 3. Will (Hf 0.2 Zr 0.2 Nb 0.2 Ta 0.2 Cr 0.2 )B 2 Multivariate high-entropy solid-melt powder is the raw material powder, put it into a graphite mold, raise the temperature to 2000°C at a heating rate of 300°C / min, keep it warm for 5min, pressurize at 80MPa, and fill it with Ar gas at 1200°C, pass Spark plasma (SPS...

Embodiment 2

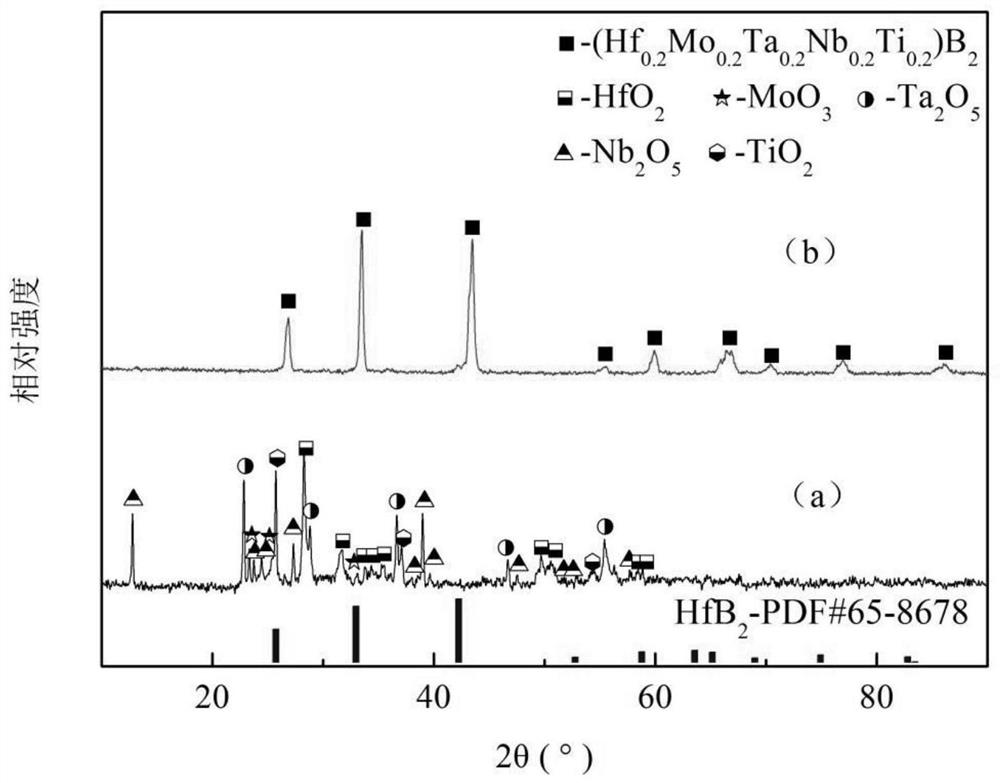

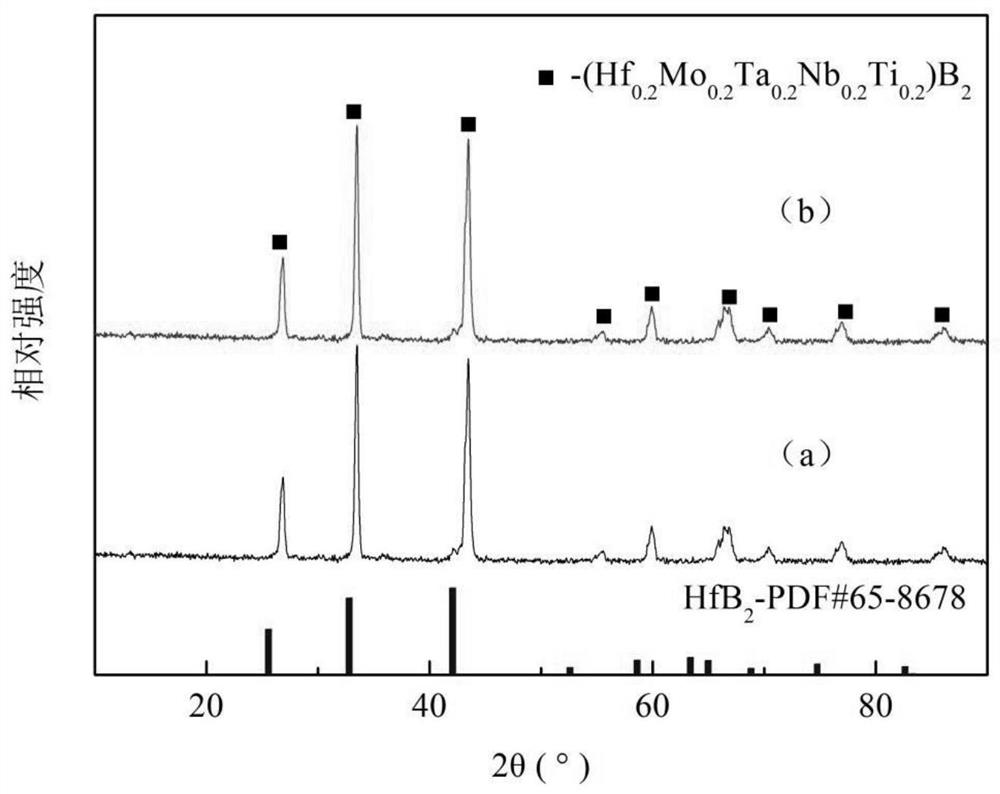

[0036] 1. With HfO 2 、MoO 3 , Nb 2 o 5 、 Ta 2 o 5 and TiO 2 And amorphous boron powder as raw material, with ethanol as solvent, with Si 3 N 4 The ball is the ball milling medium, mixed on the ball mill, and the mixed powder is obtained after drying;

[0037] 2. Put the green body obtained after the mixed powder into a graphite crucible, raise the temperature to 1100°C at a rate of 10°C / min and keep it for 1h, then raise the temperature to 1550°C at a rate of 10°C / min and keep it for 1h, after vacuum heat treatment Get (Hf 0.2 Mo 0.2 Ta 0.2 Nb 0.2 Ti 0.2 )B 2 Ultrafine high entropy solid solution powder.

[0038] 3. Will (Hf 0.2 Mo 0.2 Ta 0.2 Nb 0.2 Ti 0.2 )B 2 Put the multi-element high-entropy solid-melt powder into a graphite mold, raise the temperature to 1800°C at a heating rate of 200°C / min, hold it for 5 minutes, pressurize at 40MPa, and fill Ar gas at 1200°C, and obtain multi-element high-entropy ceramics by discharge plasma sintering Material.

...

Embodiment 3

[0043] 1. With HfO 2 , ZrO 2 , Nb 2 o 5 、MoO 3 and Cr 2 o 3 And amorphous boron powder as raw material, with ethanol as solvent, with Si 3 N 4 The ball is the ball milling medium, mixed on the ball mill, and the mixed powder is obtained after drying;

[0044] 2. Put the green body obtained after the mixed powder is molded into a graphite crucible, raise the temperature to 1000°C at a rate of 10°C / min and keep it for 1h, then raise the temperature to 1550°C at a rate of 10°C / min and keep it for 1h, after vacuum heat treatment The acquisition (Hf 0.2 Zr 0.2 Nb 0.2 Mo 0.2 Cr 0.2 )B 2 Ultrafine high entropy solid solution powder;

[0045] 3. Will (Hf 0.2 Zr 0.2 Nb 0.2 Mo 0.2 Cr 0.2 )B 2 Put the multi-element high-entropy solid-melt powder into a graphite mold, raise the temperature to 2000°C at a heating rate of 100°C / min, keep it warm for 30min, pressurize at 10MPa, fill with Ar gas at 1200°C, and sinter with multi-element High entropy ceramic materials.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com