Method for measuring fracture toughness of large thickness, high toughness hard film on metal surface

A metal surface, fracture toughness technology, applied in the direction of testing material hardness, etc., can solve problems such as improper loading capacity, lowering the cracking threshold of hard film, etc., to achieve the effect of improving accuracy, accurate results and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The method of the present embodiment comprises the following steps:

[0049] Step 1, the Vickers indenter is installed on the microhardness tester, and then the TiN film vapor deposited on the surface of the M2 high speed steel is placed on the stage of the microhardness tester; the vapor deposition on the surface of the M2 high speed steel is The thickness of the TiN film is 25.6 μm;

[0050] Step 2. Adjust the position of the stage until the surface morphology of the TiN film vapor deposited on the surface of the M2 high-speed steel can be clearly observed from the eyepiece of the microhardness tester, and then fix the position of the stage;

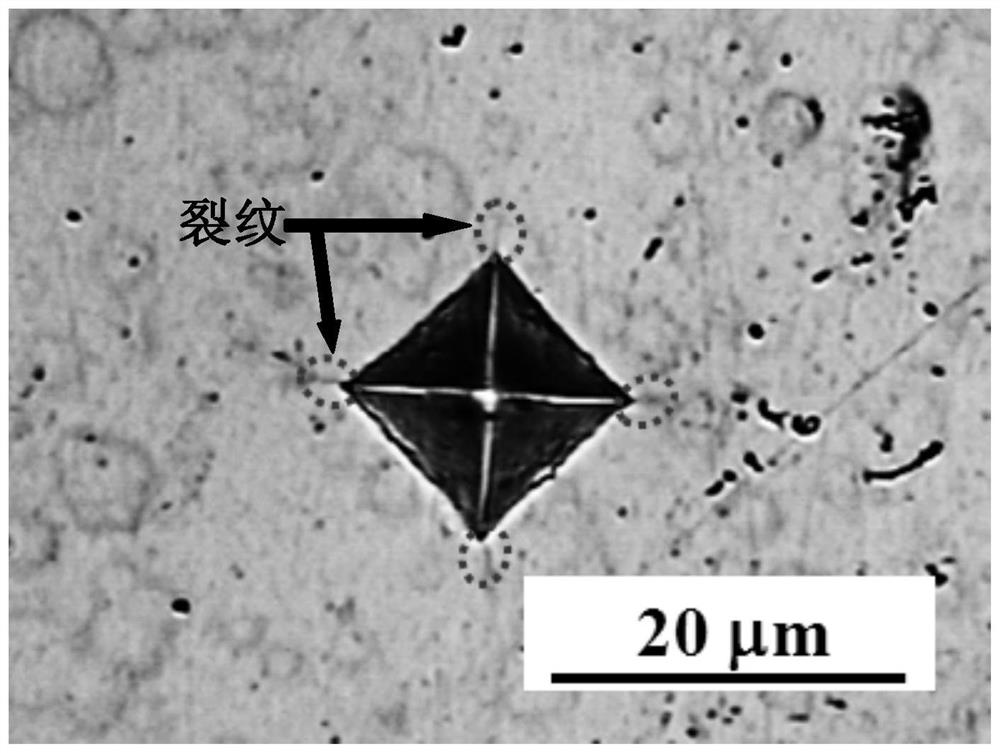

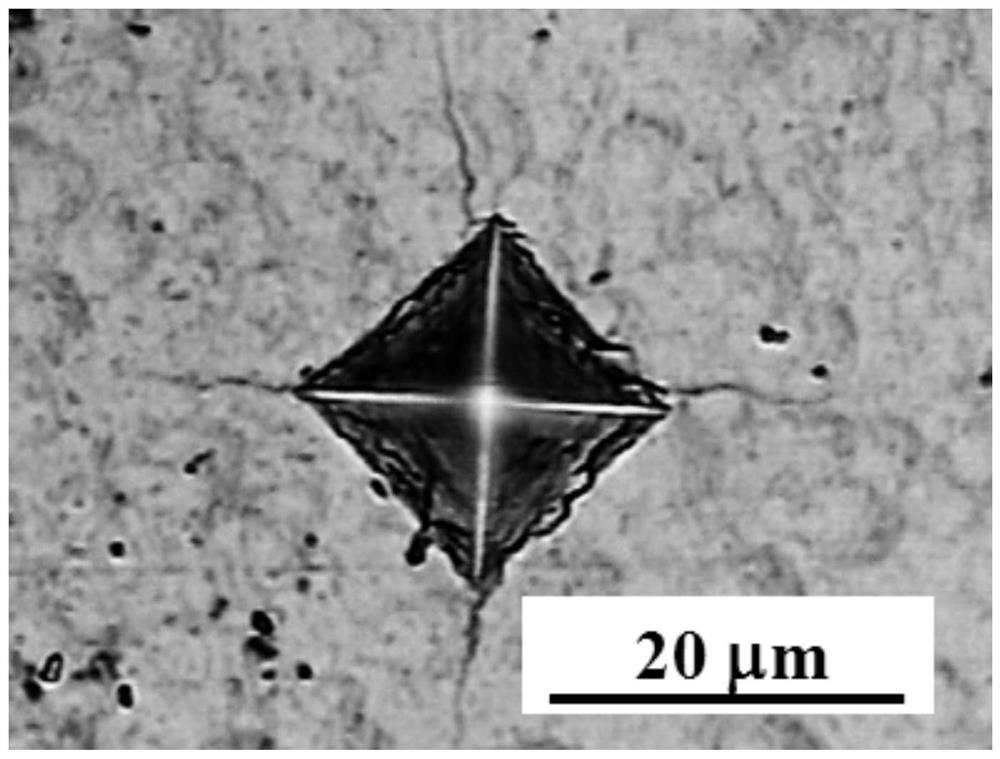

[0051] Step 3. Carry out a small load loading test on the TiN film vapor deposited on the surface of M2 high speed steel placed on the stage in step 2. The specific process is: first, the TiN film vapor deposited on the surface of M2 high speed steel is subjected to a preset load Carry out loading and holding in sequence, and t...

Embodiment 2

[0075] The method of the present embodiment comprises the following steps:

[0076] Step 1, the Vickers indenter is installed on the microhardness tester, and then the TiN film vapor deposited on the surface of the M2 high speed steel is placed on the stage of the microhardness tester; the vapor deposition on the surface of the M2 high speed steel is The thickness of the TiN film is 25.6 μm;

[0077] Step 2. Adjust the position of the stage until the surface morphology of the TiN film vapor deposited on the surface of the M2 high-speed steel can be clearly observed from the eyepiece of the microhardness tester, and then fix the position of the stage;

[0078]Step 3. Carry out a small load loading test on the TiN film vapor deposited on the surface of M2 high speed steel placed on the stage in step 2. The specific process is: first, the TiN film vapor deposited on the surface of M2 high speed steel is subjected to a preset load Carry out loading and holding in sequence, and th...

Embodiment 3

[0089] The method of the present embodiment comprises the following steps:

[0090] Step 1, the Vickers indenter is installed on the microhardness tester, and then the CrN film deposited on the surface of the M2 high speed steel is placed on the stage of the microhardness tester; the vapor deposition on the surface of the M2 high speed steel is The thickness of the CrN film is 15.5 μm;

[0091] Step 2. Adjust the position of the stage until the surface morphology of the CrN film vapor deposited on the surface of the M2 high-speed steel can be clearly observed from the eyepiece of the microhardness tester, and then fix the position of the stage;

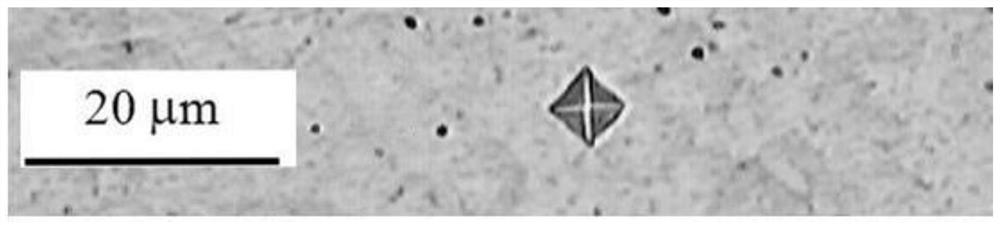

[0092] Step 3. Carry out a small load loading test on the CrN film vapor deposited on the surface of M2 high speed steel placed on the stage in step 2. The specific process is: first, according to the preset load, the CrN film vapor deposited on the surface of M2 high speed steel Carry out loading and holding in sequence, and then co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com