Mask plate, display substrate and manufacturing method thereof, display panel

A technology for display substrates and masks, which is applied in the photolithographic process of patterned surfaces, semiconductor/solid-state device manufacturing, instruments, etc., and can solve the problem of strict masking process requirements at the edge of display substrates and a large number of film masks , high process cost and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0045] After repeated studies, the inventors of the present invention found that the reasons for the step effect at the edge of the display area of the existing display panel are as follows:

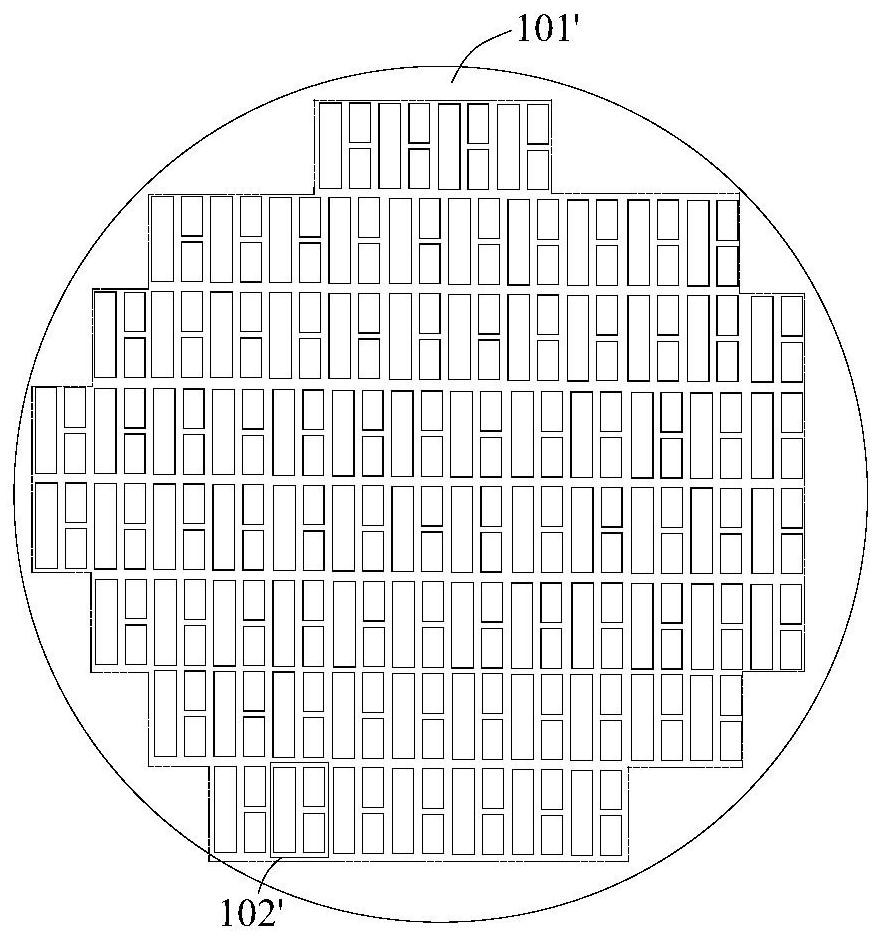

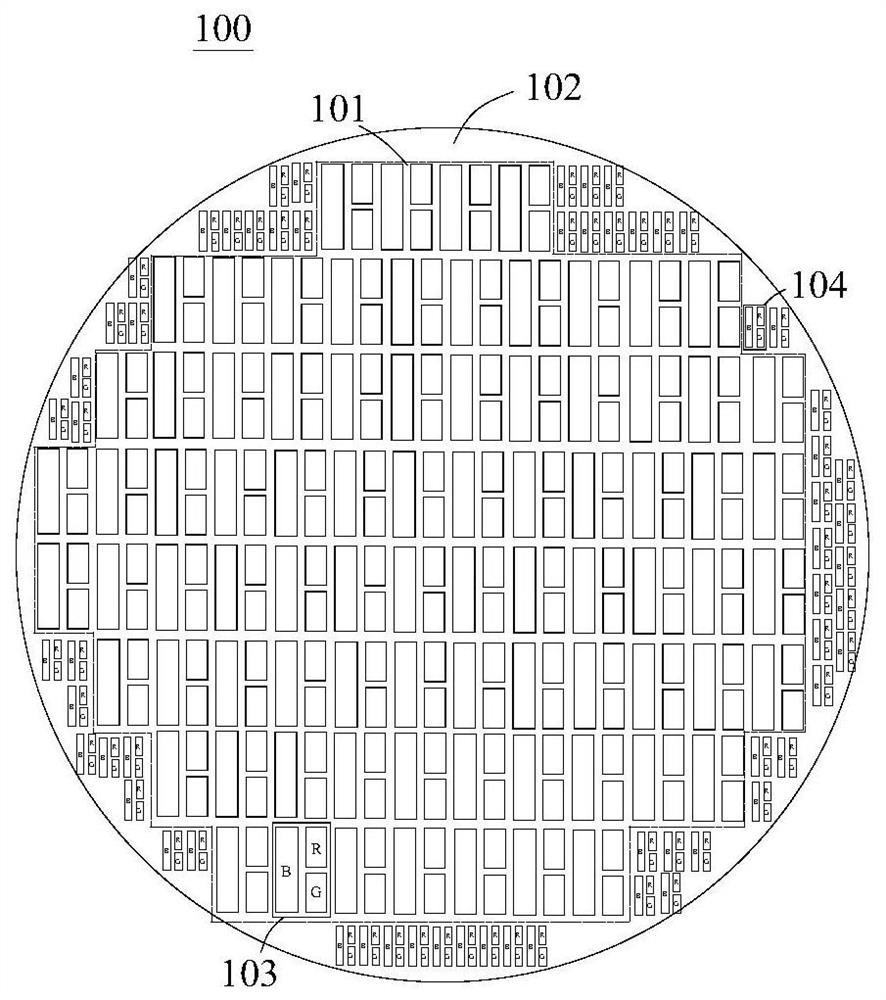

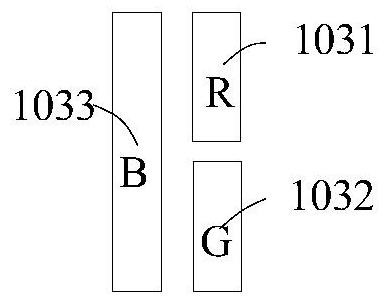

[0046] In the display panel in the prior art, the edges of the pixel units are mostly straight lines, such as figure 1 As shown, the edges of the pixel units 102' in each row are straight sides, and for a display panel with curved edges, there must be gaps between the pixel units whose edges are straight lines and the curved edges of the display panel without pixel units. The blank area 101 ′, which results in that when the display panel is displaying, the blank area 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com