A multi-axis ball-jointed 3D printing carrier for a variable-forming model

A technology of 3D printing and carrying platform, which is applied in the direction of processing platform/substrate, additive processing, etc., to achieve the effect of improving line speed, saving materials, and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

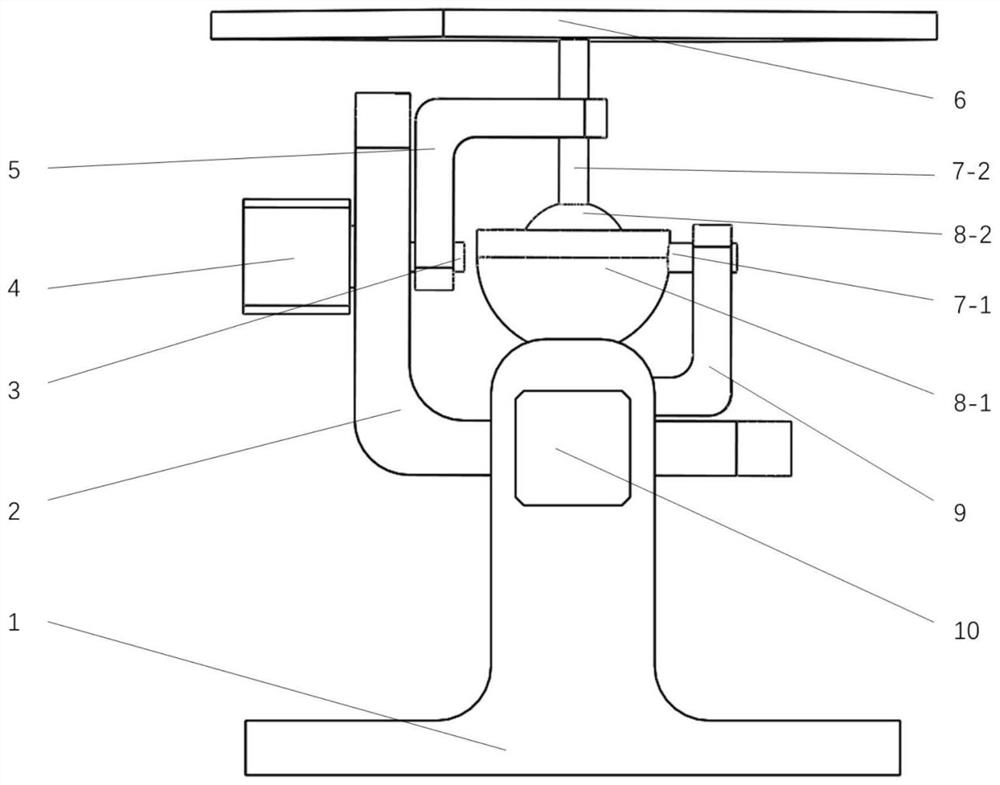

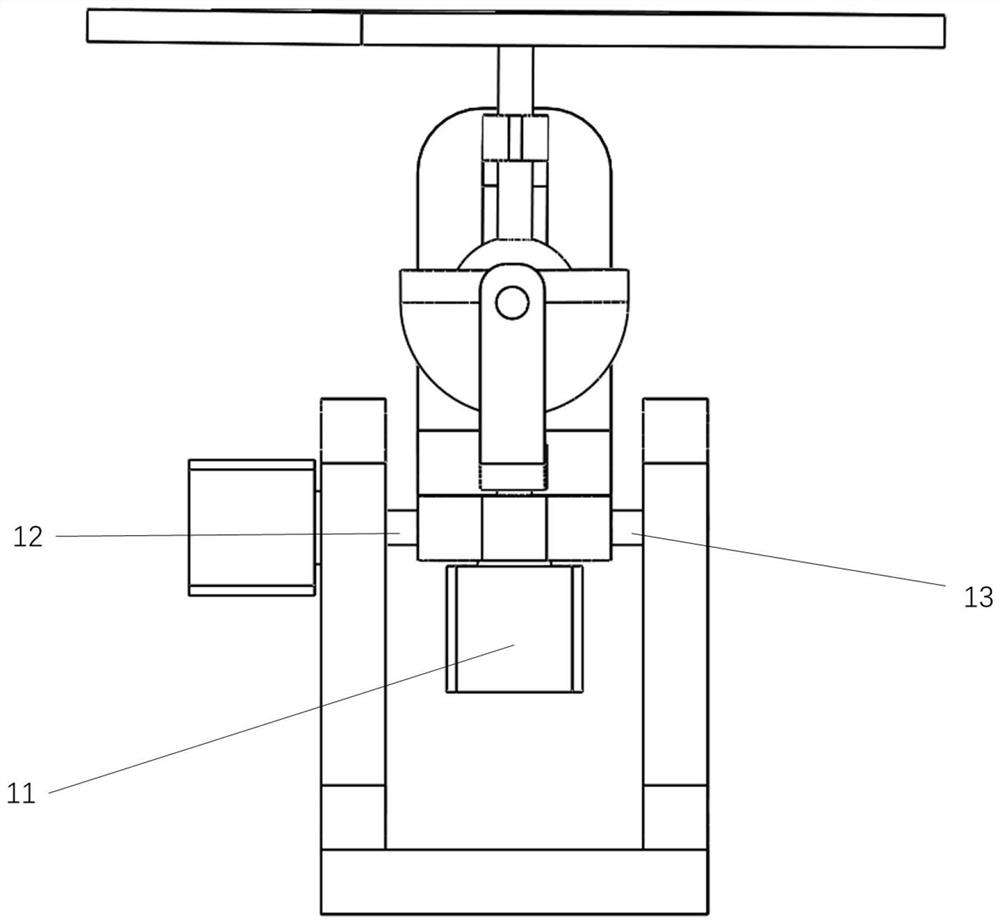

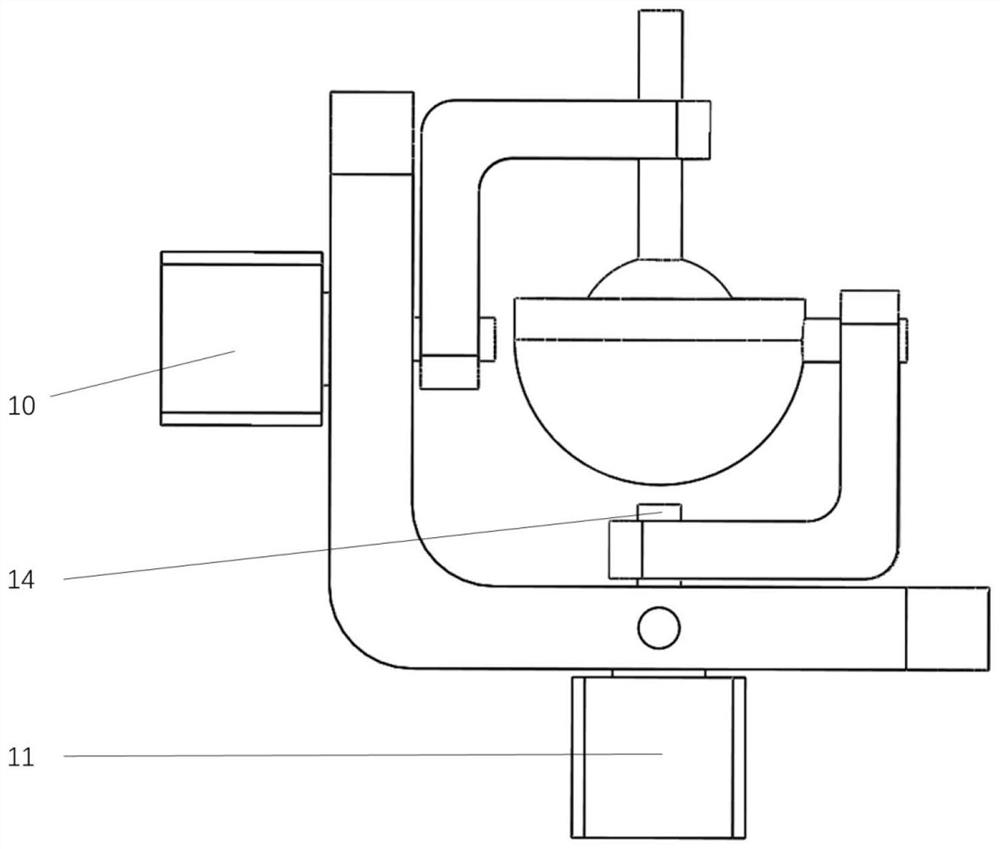

[0023] Below in conjunction with each accompanying drawing, present embodiment is described in detail:

[0024] The specific implementation of the printing platform system includes a pose feedback system, a printing platform and a multi-axis ball-articulated three-dimensional printing platform device.

[0025] The pose feedback system includes a gravity sensor fixed on the printing platform for judging the horizontal direction and a photoelectric sensor fixed on the multi-axis ball-jointed 3D printing platform device for judging the rotation angle; the printing platform is installed on the multi-axis ball joint On the three-dimensional printing platform device, the three-dimensional printing platform device is hinged by a multi-axis ball to adjust the spatial position of the printing platform.

[0026] Such as Figure 1-Figure 3 As shown, the multi-axis ball-articulated three-dimensional printing platform device includes a frame 1, an L-shaped fixed frame 2, a second motor sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com