Drilling machine drill bit

A drill bit and drilling machine technology, applied in drilling/drilling equipment, components of boring machine/drilling machine, repairing drilling, etc. The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

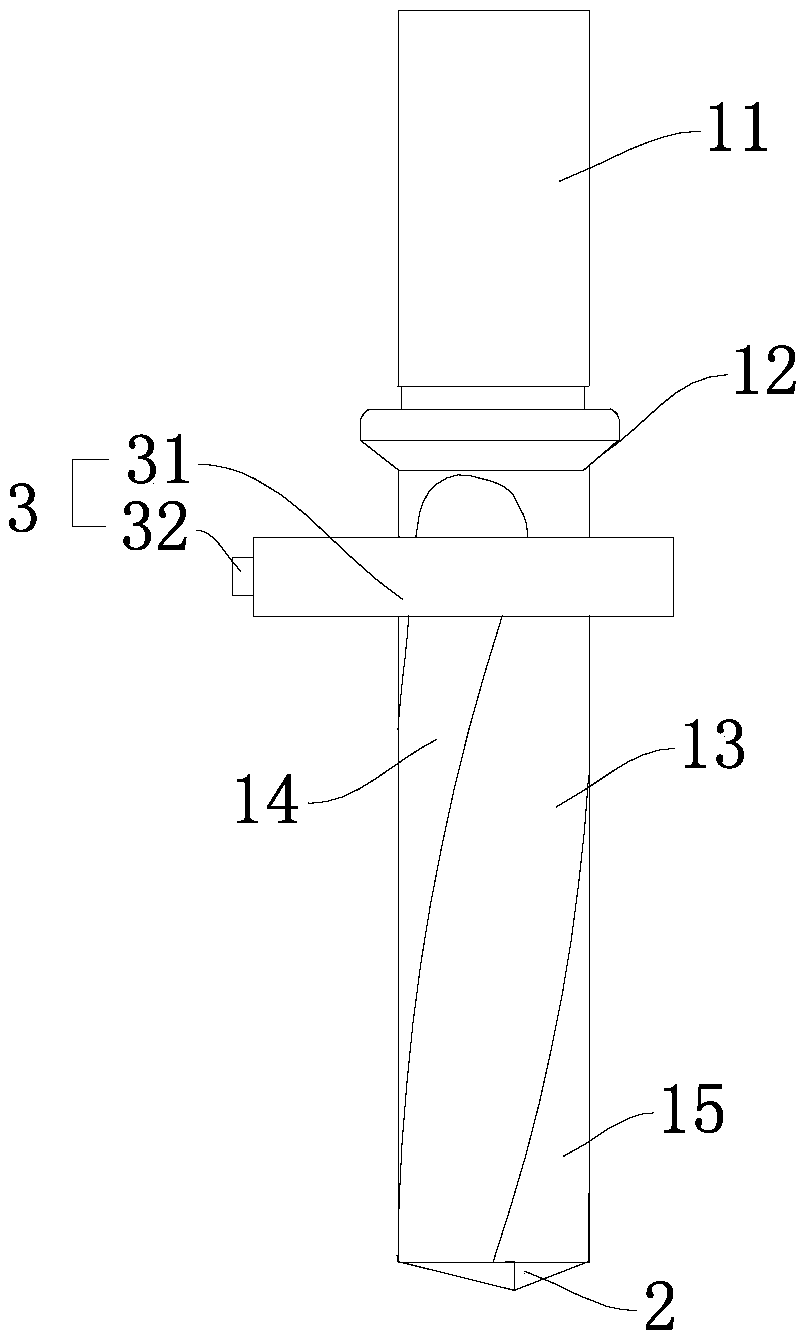

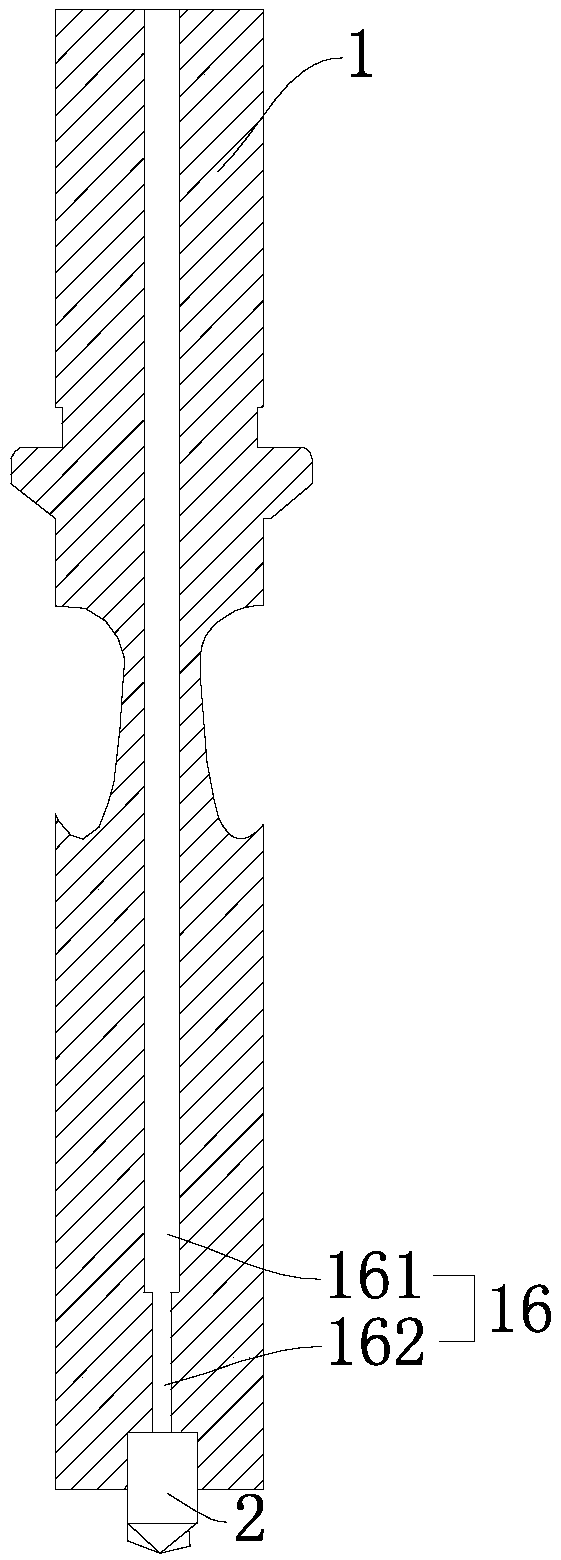

[0016] Such as Figure 1 to Figure 3 The shown drilling bit includes a cutter body, a drill 2 and a stopper 3. The cutter body is a connection part 11, a mounting part 12 and a cutter bar part 13 from top to bottom, and the drill cutter 2 is connected to the cutter bar part 13. lower end;

[0017] The first chip removal flute 14 and the second chip removal flute 15 opposite and spirally arranged are provided on the cutter bar part 13, and the first chip removal flute 14 and the second chip removal flute 15 extend from the end surface of the cutter bar part 13 to the mounting part 12;

[0018] When the drill bit is drilling, chips can be discharged outwards along the first chip flute and the second chip flute, thereby avoiding the generation of clogging caused by chips and improving the working efficiency of the present invention.

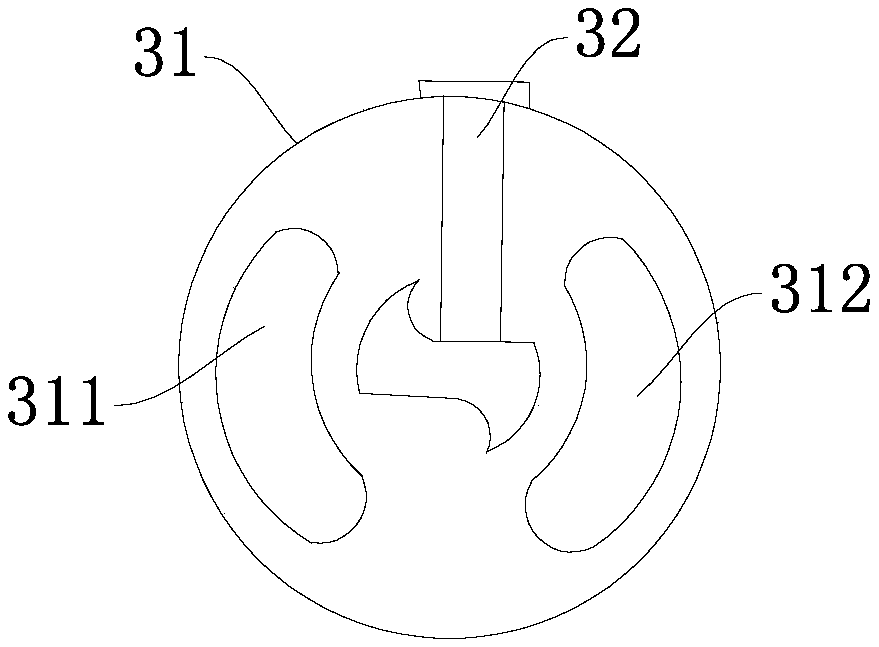

[0019] The limit device 3 comprises a limit sleeve 31 and a set screw 32, the limit cover 31 can be screwed on the knife bar portion 13, the limi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com