Punching cutter device specially for processing soft flat profile part

A punching knife and flat type technology, which is used in the field of punching cutter devices for processing soft flat profile parts, can solve problems such as adverse effects on the appearance of parts, meet the requirements of size and appearance, and the soft material needs to be punched in the middle of the surface. area smoothing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings.

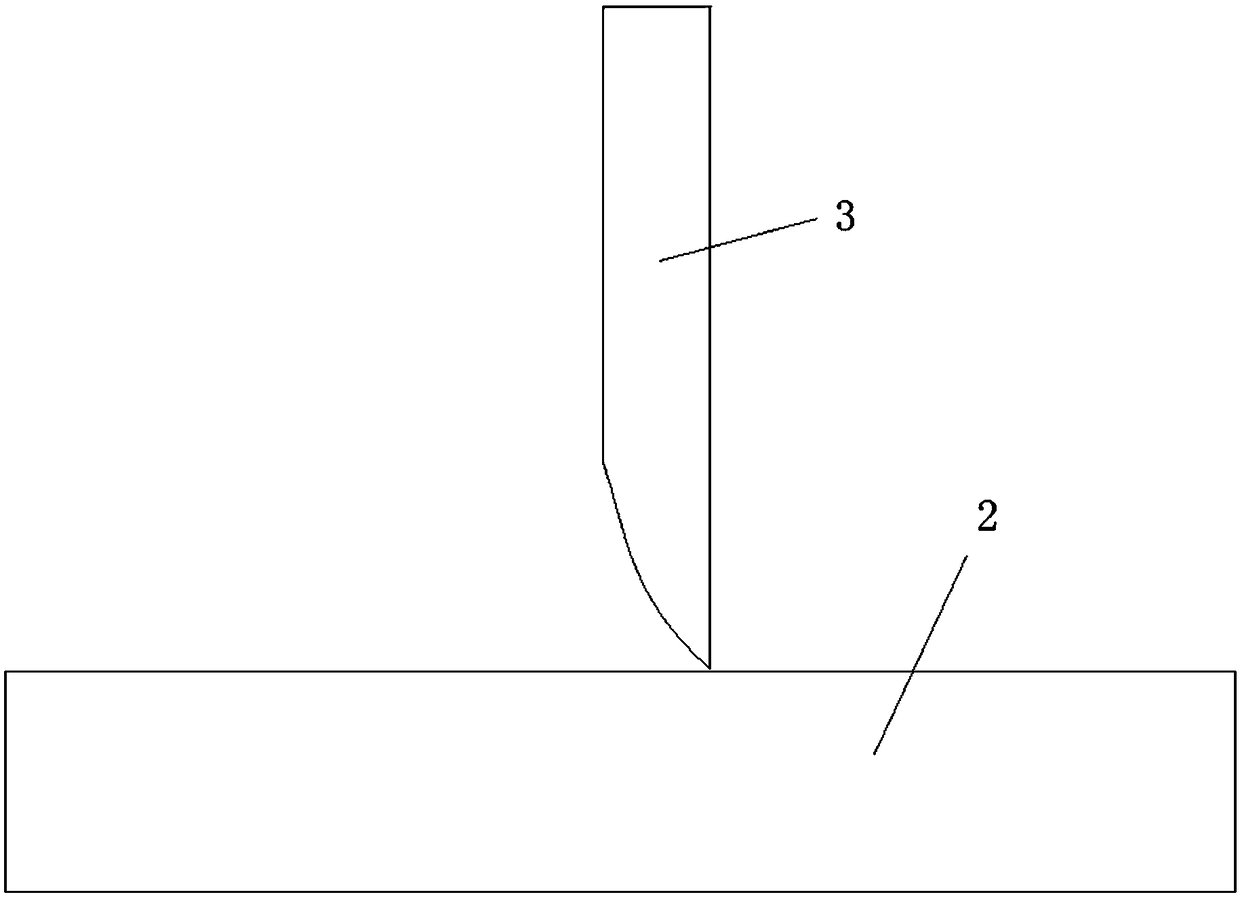

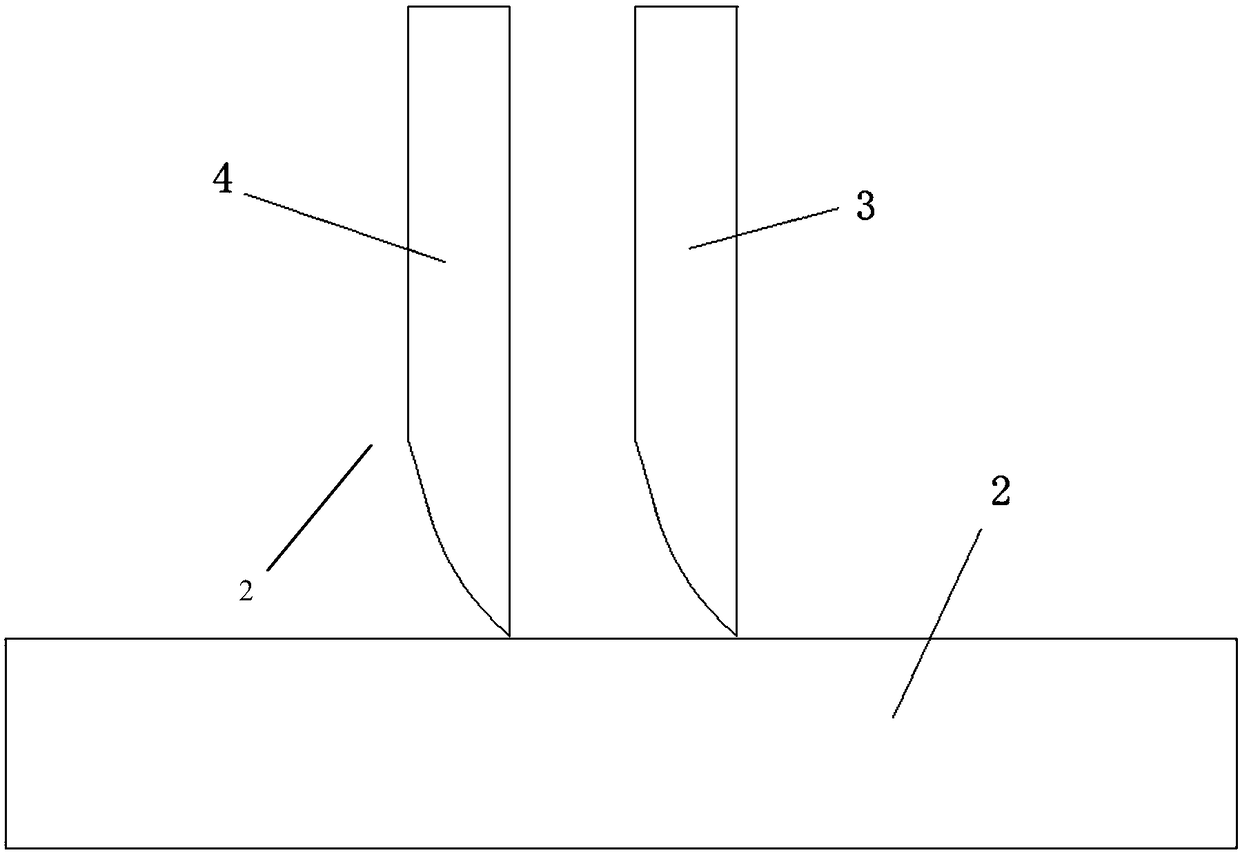

[0027] In the punching knife device specially used for processing soft flat surface parts proposed in an embodiment of the present invention, its structure can be found in Figure 5 and Figure 6 As shown, it mainly includes a knife seat and a punching knife unit 1 installed on the knife seat. The punching knife unit 1 is composed of two punching knife heads arranged in parallel at intervals. The two punching knife heads are respectively the first punching knife The cutting head 3 and the second punching head 4, the side of the punching head facing the soft flat surface part to be processed is in a vertical plane shape, and the corresponding other side is an arc surface that is inclined outward and has a smooth transition shape.

[0028] When the punching knife in the above-mentioned embodiment is punching the soft flat surface parts, such as when processing the PE...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com