Protective structure of a highway bridge

A technology for protective structures and highway bridges, applied in bridges, bridge construction, bridge parts, etc., can solve the problems of large temperature difference, uneven road surface of highway bridges, and enlarged gaps, so as to avoid weathering, prolong service life, and achieve better protection effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

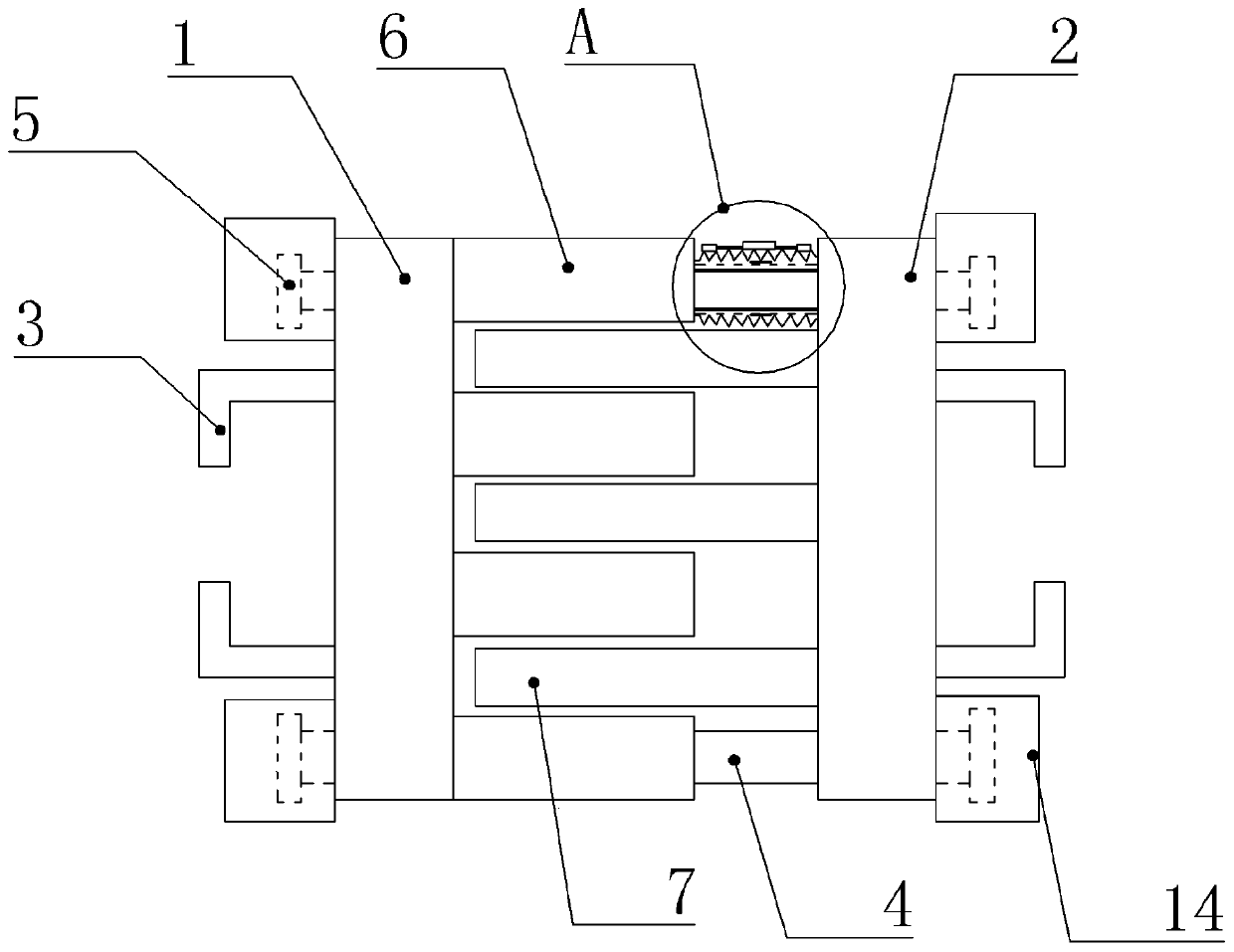

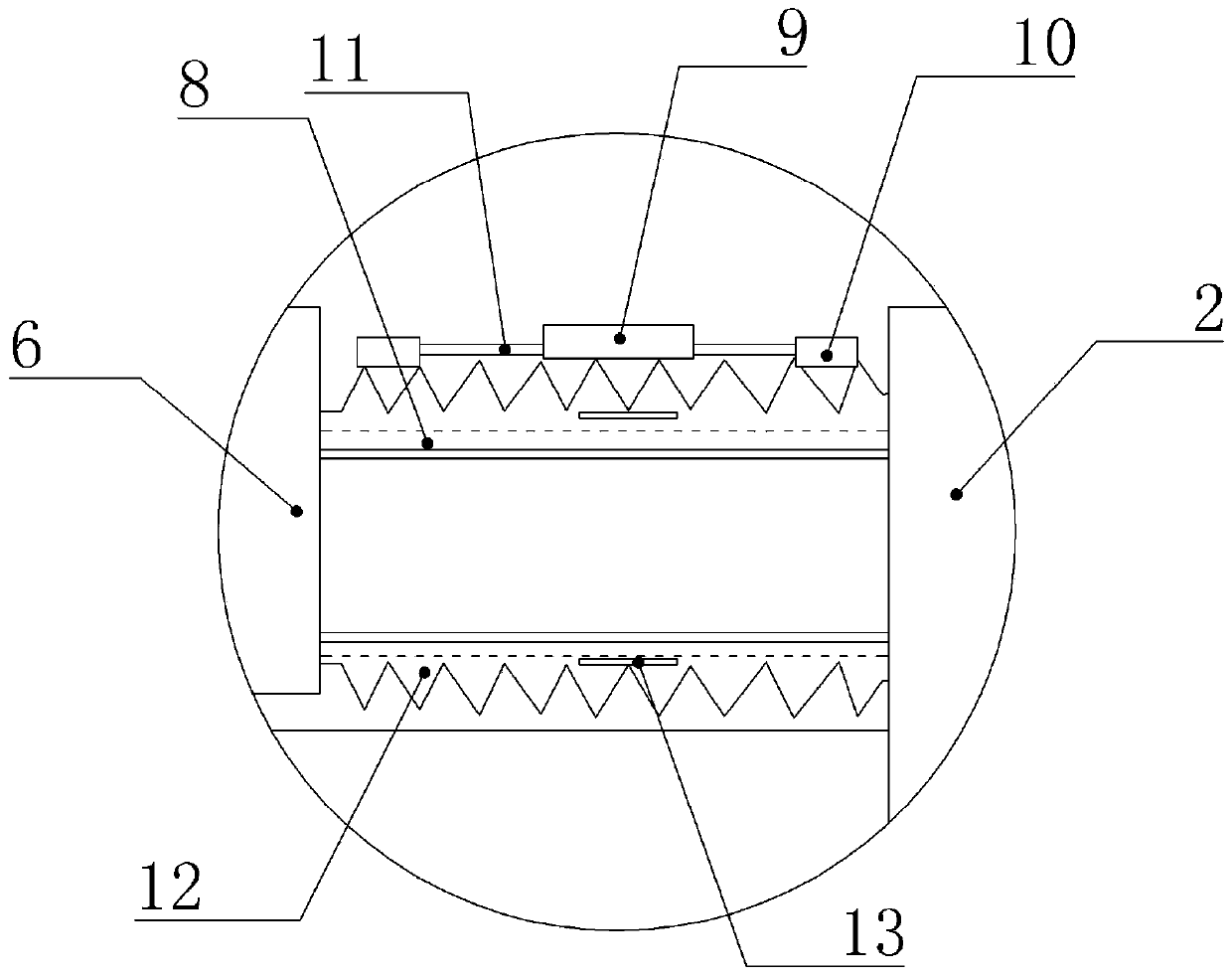

[0019] Such as figure 1 with figure 2 Shown: a protective structure of a highway bridge, including a first base 1 and a second base 2, the first base 1 and the second base 2 are vertically arranged, the first base 1 and the second base The upper ends of the bases 2 are flush, and the outer sides of the first base 1 and the second base 2 are provided with connecting parts. The connection part includes two L-shaped steel plates 3 , and the two L-shaped steel plates 3 are arranged symmetrically along the horizontal central axis of the first base 1 . The first base 1 and the second base 2 are slidably connected by a support rod 4, the upper end and the lower end of the first base 1 are provided with a first mounting hole, and the upper end and the lower end of the second base 2 are provided with a second mounting hole, The first installation hole and the second installation hole are oppositely arranged, the support rod 4 passes through the first installation hole and the second...

Embodiment 2

[0022] The difference between Embodiment 2 and Embodiment 1 is that the distance between the upper end surface of the elastic sleeve 8 and the upper end surface of the first base 1 is 2.3 cm, and this distance setting is suitable for roads where tourist vehicles in the field often travel. bridge pavement.

Embodiment 3

[0024] The difference between embodiment 3 and embodiment 1 is that the distance between the upper end surface of the elastic sleeve 8 and the upper end surface of the first base 1 is 3 cm, and this distance setting is suitable for highway bridge road surfaces where heavy-duty vehicles travel more. .

[0025] The specific implementation process is as follows: first, during the construction of the highway bridge, the L-shaped steel plate 3 and the bridge plate are fixed together, and the entire protective structure is placed at the gap between the two bridge plates. When the weather in the north becomes cold, the first base 1, the second base 2, the first splicing block 6 and the second splicing block 7 are all contracted by the cold, and the space between the first splicing block 6 and the second splicing block 7 Gap becomes bigger, and the length of elastic sleeve 8 becomes longer. Now, block 9 is also contracted by cold, because the degree of contraction of block 9 by cold ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com