Underground garage sinking-type ventilation and exhaust vertical shaft and making method thereof

An underground garage, ventilation and exhaust technology, applied in vertical pipes, buildings where cars are parked, building components, etc., can solve problems such as breeding bacteria, poor drainage, and pollute the environment, to prevent water leakage and avoid drainage. unobstructed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

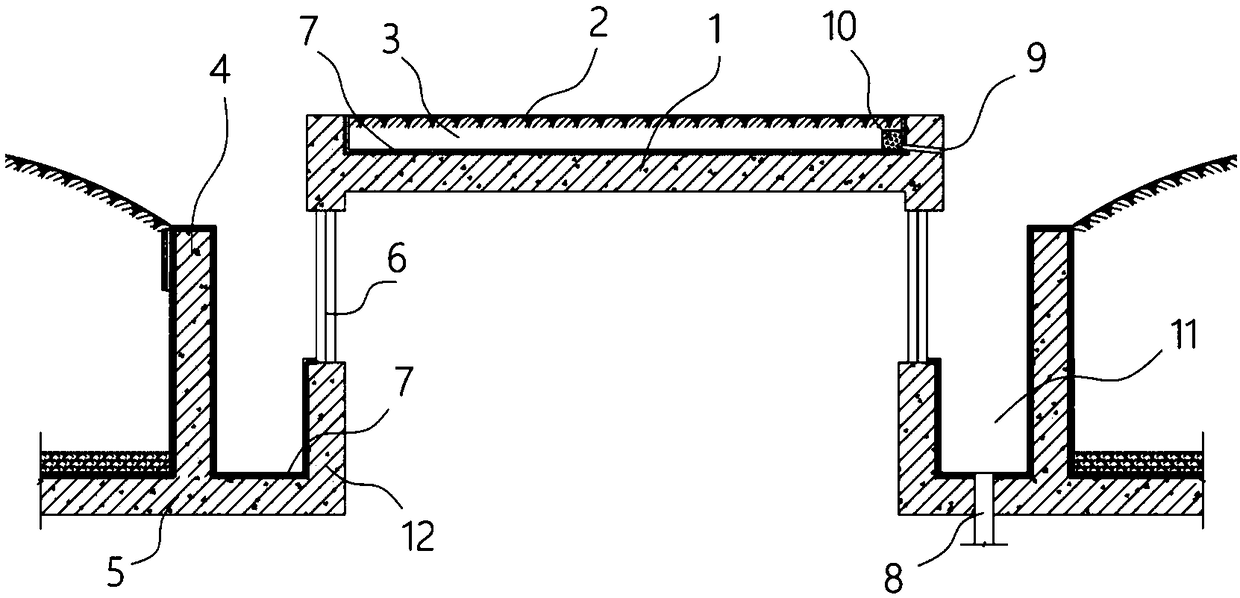

[0024] see figure 1 , a sunken ventilation and exhaust shaft for an underground garage, comprising a roof structure layer 5, a reinforced concrete retaining wall 4 is vertically arranged on the roof structure layer 5, a concrete anti-sill 12 is arranged on the roof structure layer 5, and a concrete anti-sill 12 The side wall is embedded with shutters 6, and the top of the concrete anti-sill 12 is equipped with a roof 1, and a grass mat 2 is laid on the roof 1. A drainpipe II9 runs through the wall obliquely downward.

[0025] The roof 1 is used as the top of the underground garage to keep out the rain. The rain falls on the straw mat 2 on the top of the roof 1 and can moisten the grass mat 2, so as to promote the growth of the grass mat 2 and prevent the air discharged from the shutters 6. The purification effect of rainwater flows out along the drainpipe II9 to realize the discharge of accumulated water on the roof 1.

[0026] Further, the diversion chamber 3 is provided wi...

Embodiment 2

[0029] On the basis of Embodiment 1, a method for manufacturing an underground garage sunken ventilation and exhaust shaft specifically includes the following steps:

[0030] Step 1: Build a reinforced concrete retaining wall 4 on the roof structure layer 5 of the underground garage. The height, thickness, reinforcement and concrete label of the reinforced concrete retaining wall 4 are determined according to the backfill height of the planting soil and the load on the roof structure layer 5 of the garage;

[0031] Step 2: Wrap the underground reinforced concrete retaining wall 4, the roof structure layer 5 and the concrete anti-sill 12 with SBS waterproof membrane, and turn it up to the bottom of the shutter 6 window to form a waterproof layer 7 to achieve a good waterproof effect and avoid the roof structure Layer 5 seepage of rainwater occurs.

[0032] Step 3: Prefabricate a drainage pipe I8 on the roof structure layer 5, connect the drainage pipe I8 with the basement compr...

Embodiment 3

[0035] On the basis of Embodiment 1, a method for manufacturing an underground garage sunken ventilation and exhaust shaft specifically includes the following steps:

[0036] Step 1: Build a reinforced concrete retaining wall 4 on the roof structure layer 5 of the underground garage. The height, thickness, reinforcement and concrete label of the reinforced concrete retaining wall 4 are determined according to the backfill height of the planting soil and the load on the roof structure layer 5 of the garage;

[0037] Step 2: Wrap the underground reinforced concrete retaining wall 4, the roof structure layer 5 and the concrete anti-sill 12 with SBS waterproof membrane, and turn it up to the bottom of the shutter 6 window to form a waterproof layer 7 to achieve a good waterproof effect and avoid the roof structure Layer 5 seepage of rainwater occurs.

[0038] Step 3: Prefabricate a drainage pipe I8 on the roof structure layer 5, connect the drainage pipe I8 with the basement compr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com