Aluminum pharmaceutical ointment tube inner coating performance detecting device and method

A detection device and inner coating technology, applied in the direction of measuring devices, mechanical devices, instruments, etc., can solve the problems of uneven deformation of the inner coating of the ointment tube, no published patent documents, affecting performance detection, etc., and improve the performance. The effect of landing stability, ease of operation, and ease of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

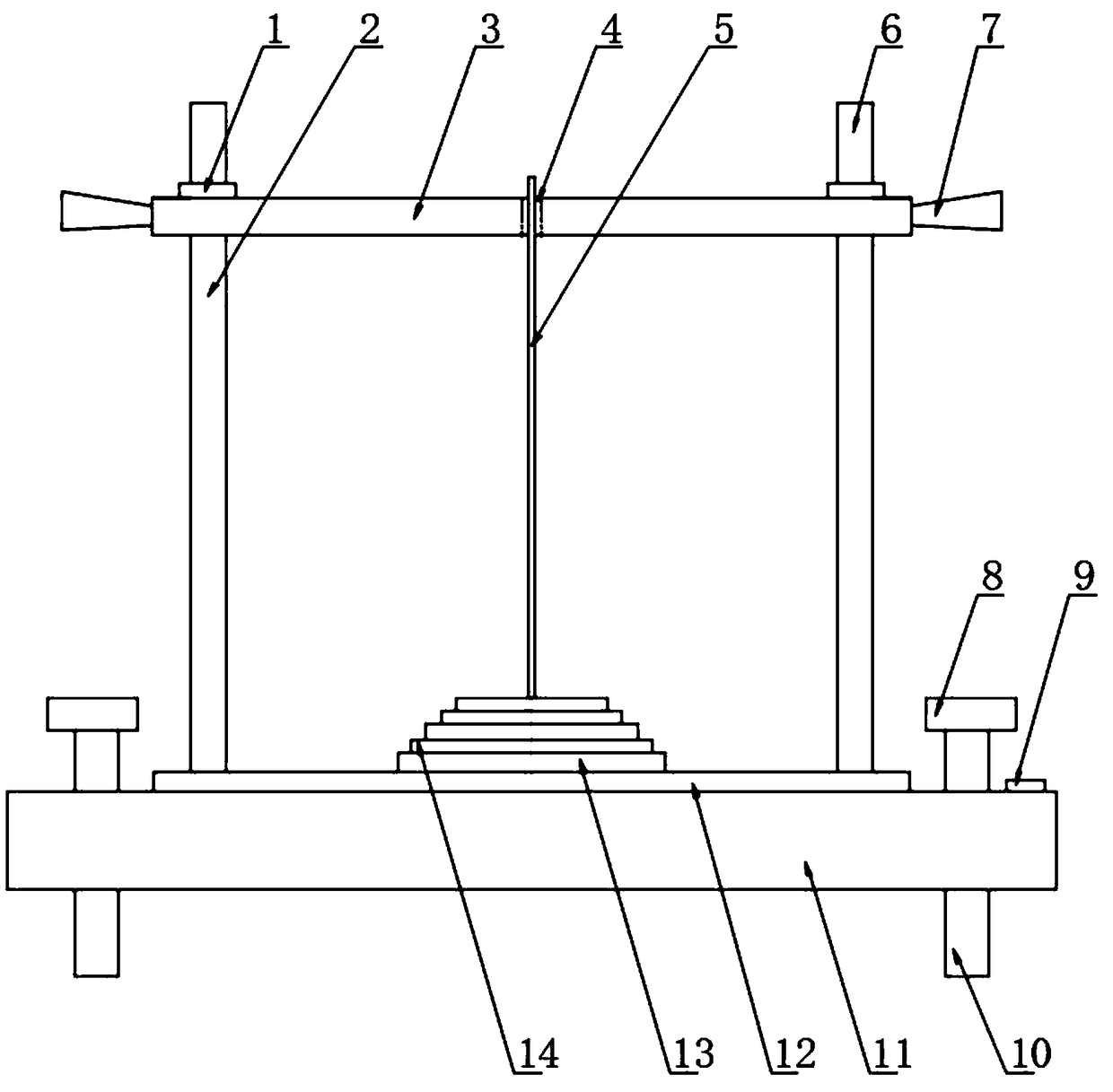

[0033] An aluminum pharmaceutical ointment tube inner coating performance testing device, the innovation of which is that it includes a base plate 11, a support stud 10, a left guide rod 2, a right guide rod 6, and a weight block 3, and the support screw is fixedly installed at the bottom of the base plate. The column, the left guide rod and the right guide rod are fixedly installed on the base plate, the left guide rod and the right guide rod are equipped with a weight block, the linear bearing 1 is installed on the weight block, and a storage platform 13 is arranged at the center of the base plate. A guide post 5 is coaxially installed, and a guide post piercing hole 4 is set at the position corresponding to the guide post of the weight blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com