Fabric defect detection device

A detection device and fabric technology, applied in the direction of optical testing flaws/defects, etc., can solve the problems of easy existence of dead corners, fabric folds, and inability to tension fabrics, etc., to speed up the detection speed, reduce labor costs, and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with specific embodiment, further illustrate the present invention.

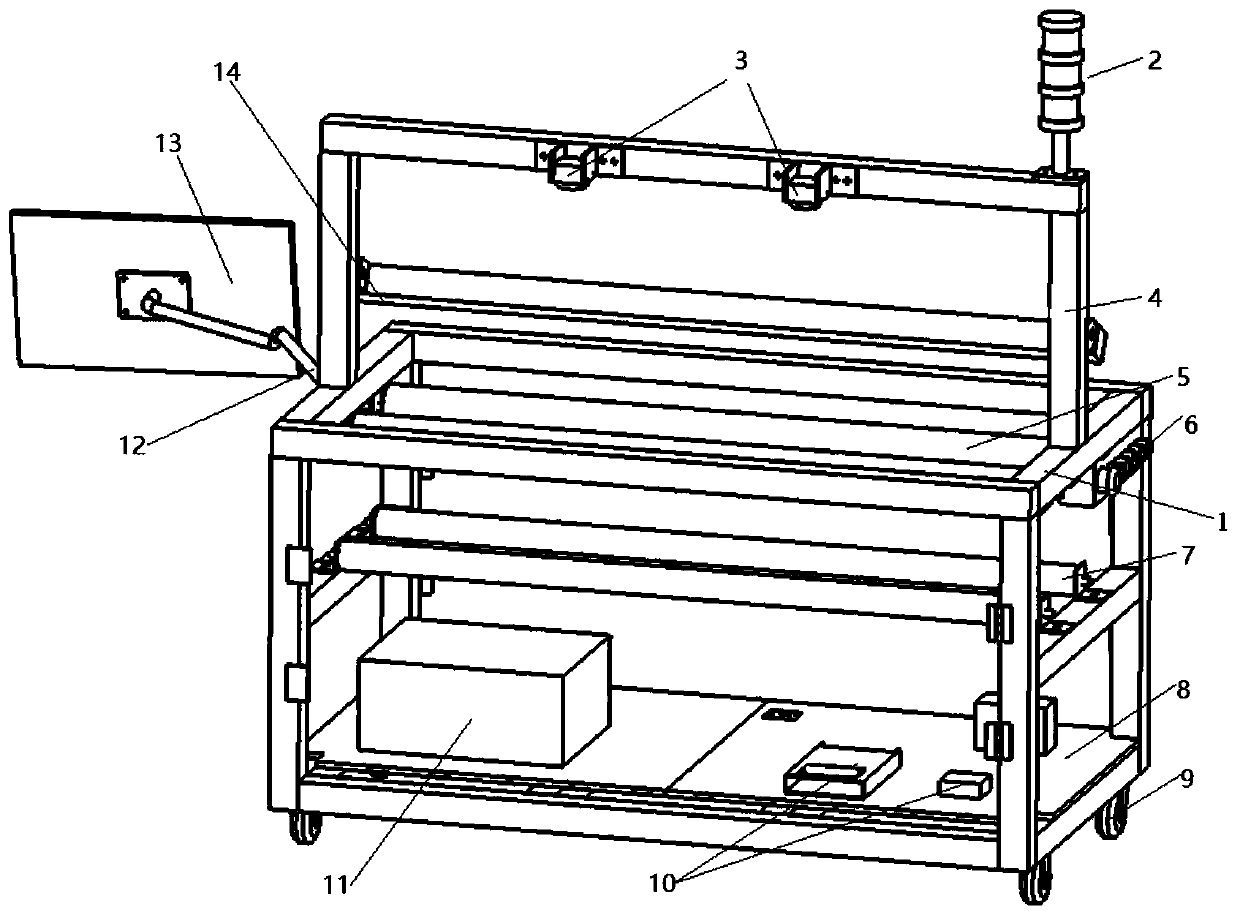

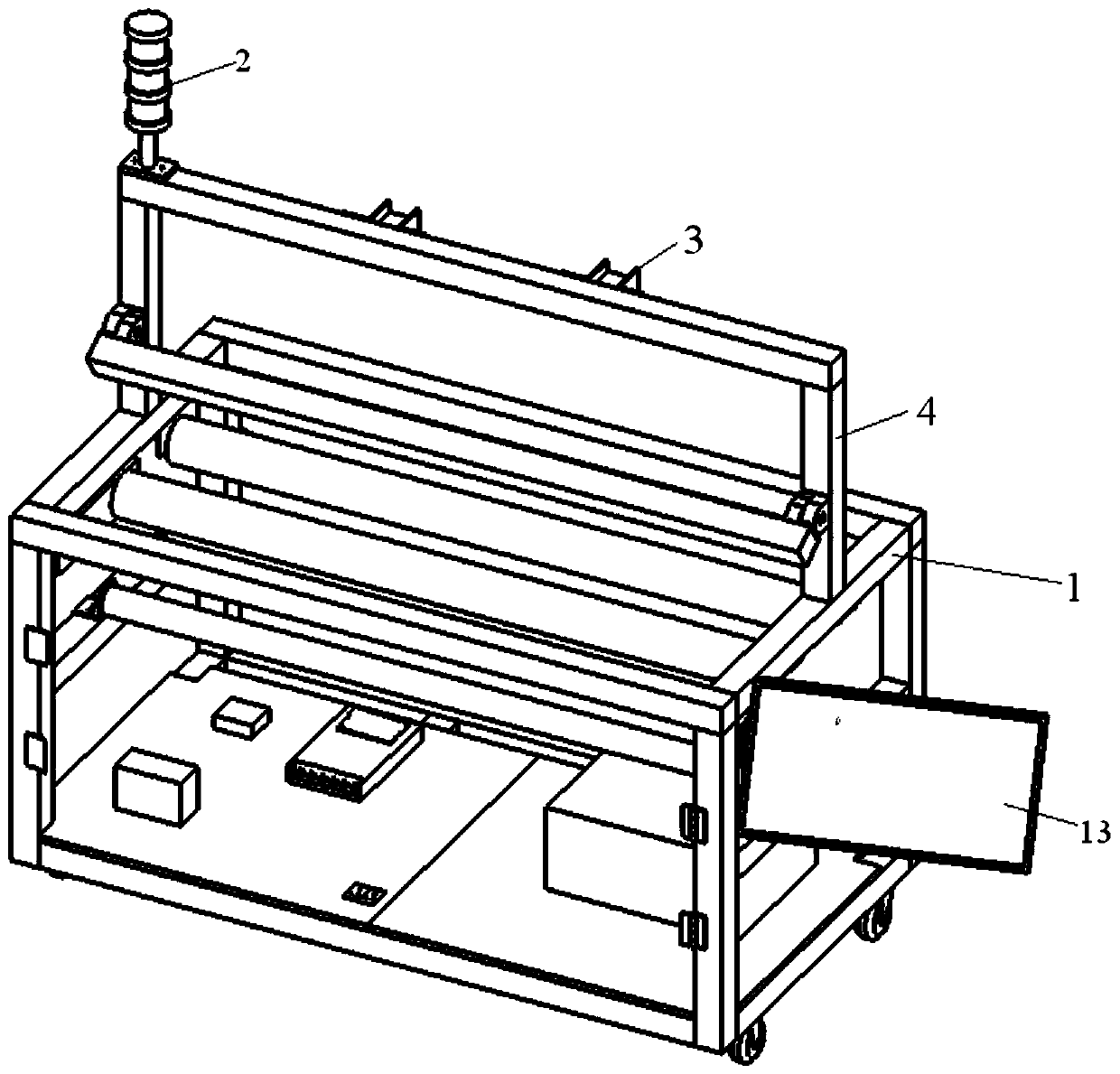

[0030] figure 1 with figure 2 The schematic diagram of the structure of the cloth defect detection device provided in this embodiment, the cloth defect detection device includes a detection platform 1, a camera bracket 4 is arranged above the detection platform 1, a line array camera 3 is installed on the upper part of the camera bracket 4, and a camera bracket 4 A three-color warning light 2 is installed on the top for displaying the working status of the machine.

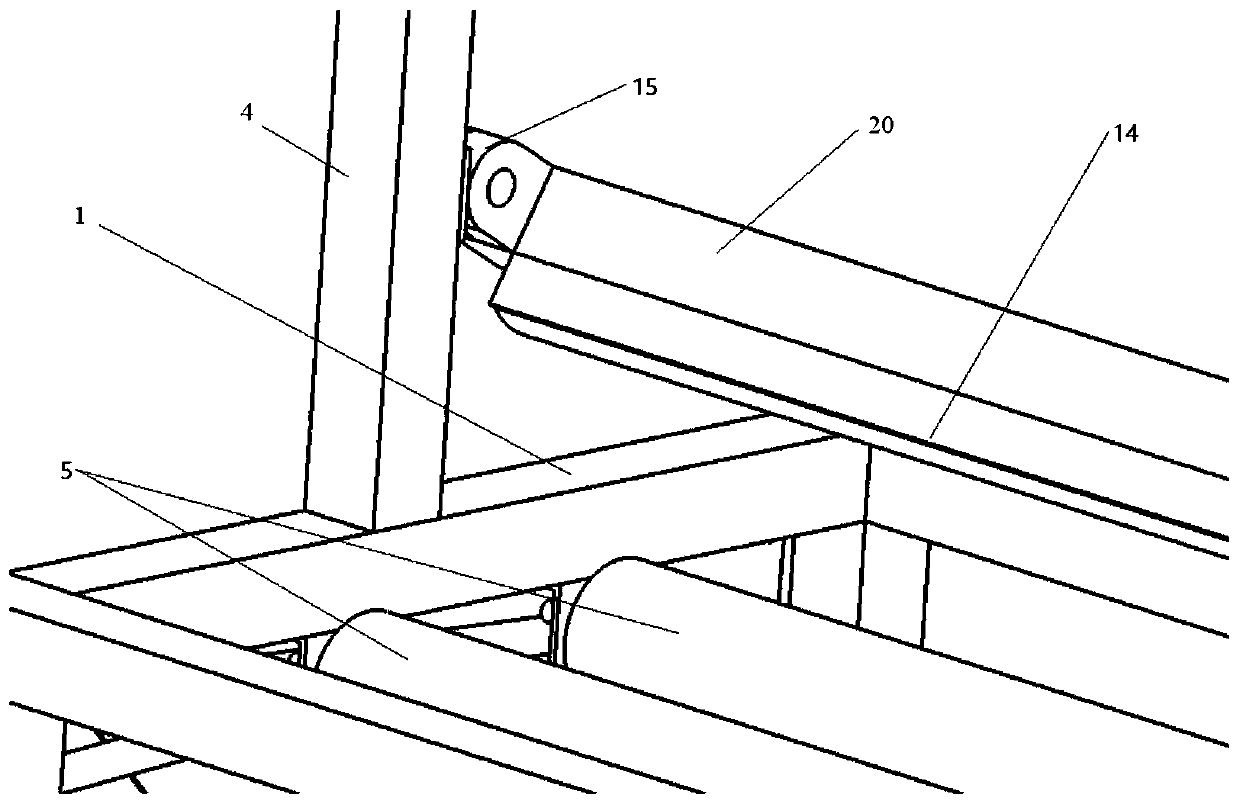

[0031] combine image 3 A pair of angle-adjustable hinges 15 are arranged on both sides of the middle and lower part of the camera bracket 4 , and the other end of the angle-adjustable hinge 15 is connected to a light source bracket 20 , and a linear light source 14 is provided on the light source bracket 20 . The angle between the camera bracket 4 and the light source bracket 20 can be adjusted. The position of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com