Defect detection imaging system of railway overhead contact system supporting mechanism

A technology for support mechanism and defect detection, which is applied in railway vehicle shape measuring instruments, testing of machine/structural components, railway car body components, etc., can solve problems such as insufficient comprehensiveness, low imaging resolution, redundant data detection information, etc. Achieve the effect of fewer devices, strong system stability, and avoidance of strong light interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

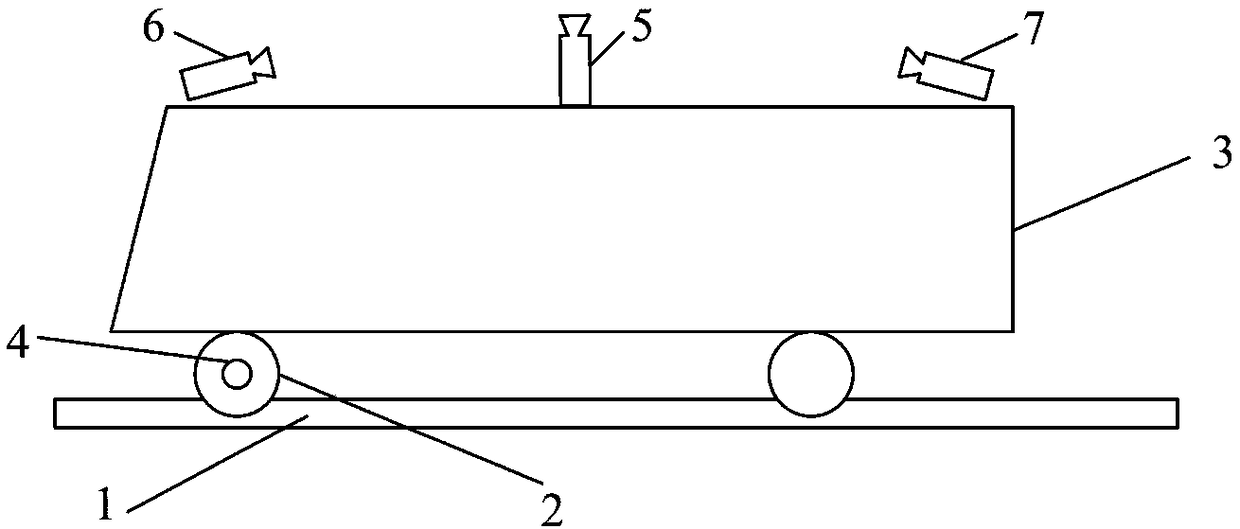

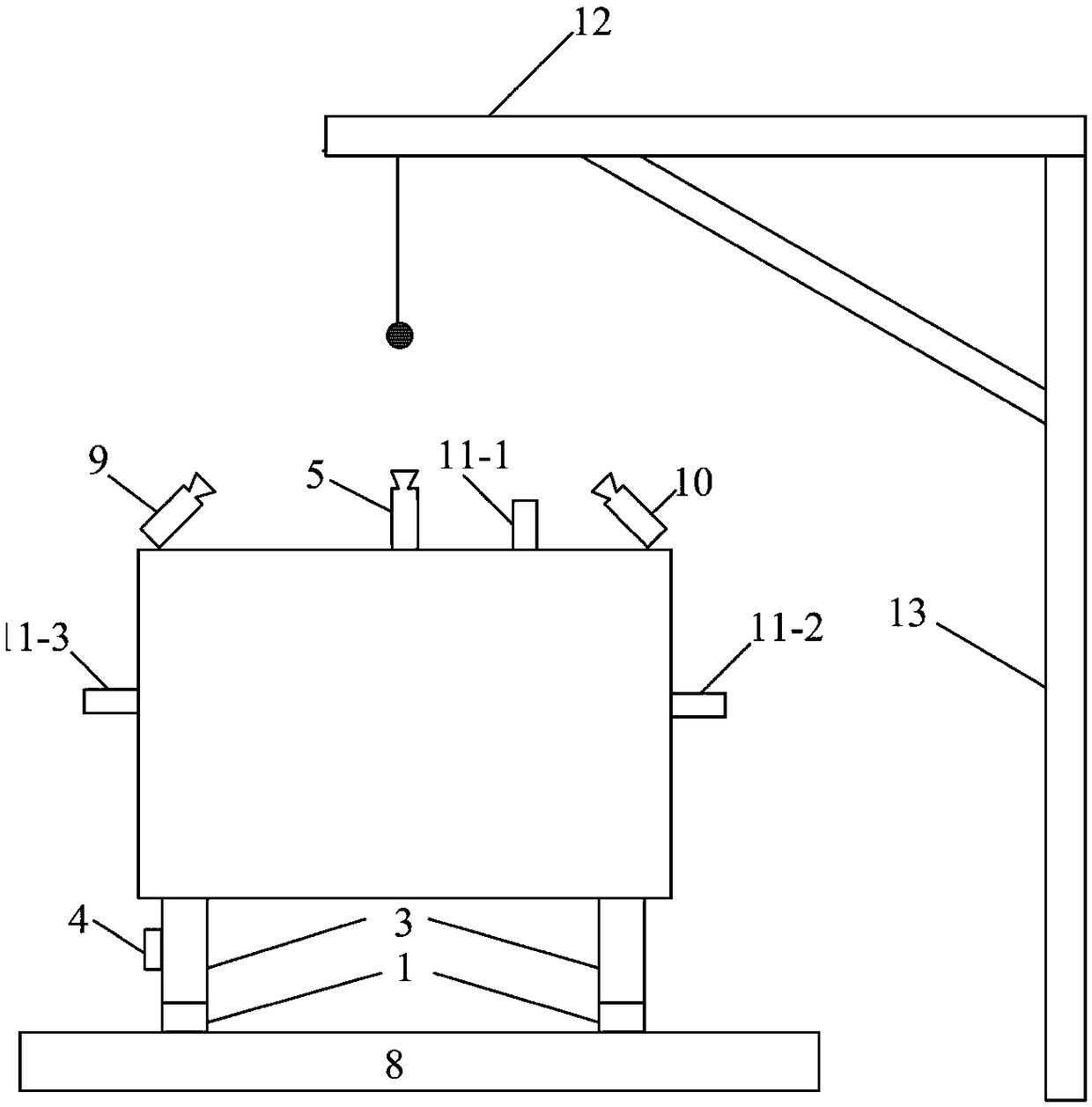

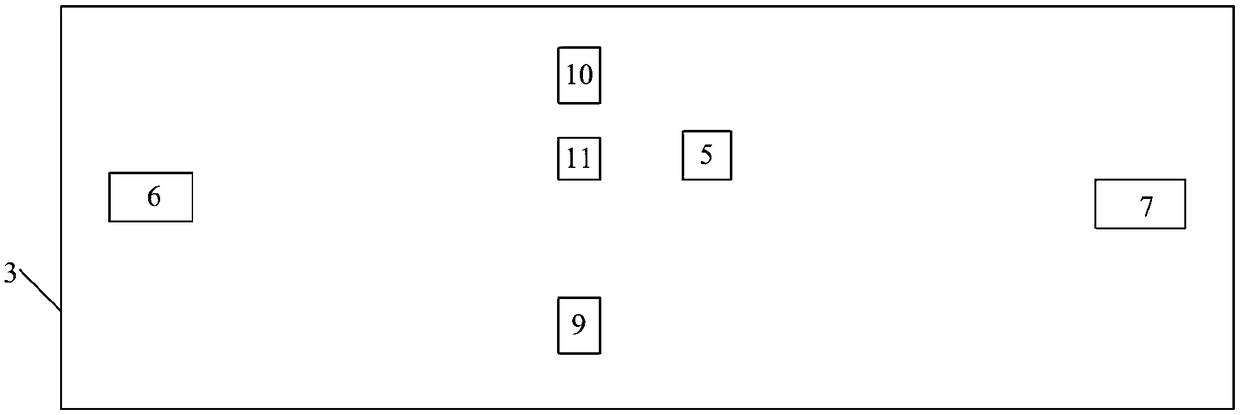

[0042] as attached figure 1 Shown is a longitudinal view of the imaging system of the present invention, with figure 2 Shown is the lateral view of the imaging system of the present invention, with image 3 Shown is the top view of the imaging device of the present invention, the railway catenary support mechanism defect detection imaging system designed by the present invention, by the imaging trigger module, four area array cameras A1 (9), A2 (10), A3 (6), A4 ( 7), composed of a line array camera 5, four surface light sources, line light source, industrial computer and power supply interface,

[0043]The imaging trigger module is composed of three photoelectric proximity switches 11, a photoelectric code disc 4 and a signal processing module. The three photoelectric proximity switches 11 are respectively located on the top and both sides of the detection platform, and are used to sense the approaching objects in the areas above the compartment 3 and on both sides. , when ...

Embodiment 2

[0065] In embodiment 2, four area array cameras A1 (9), A2 (10), A3 (6), A4 (7) and line array cameras 5 are monochromatic image sensors, and in area array cameras A1 (9), A2(10), A3(6), A4(7) and line array cameras 5 are equipped with a narrow band-pass filter with a wavelength b at the front end, the surface light source and line light source are monochromatic light sources with a wavelength b, and the wavelength b is 808nm .

[0066] All the other devices are the same as in Example 1.

Embodiment 3

[0068] In embodiment 3, four area array cameras A1 (9), A2 (10), A3 (6), A4 (7) and line array cameras 5 are monochrome image sensors, and the surface light source and line light source are monochrome light sources, The wavelength of the surface light source that provides illumination for the area array camera A1 (9) is e1, the wavelength of the surface light source that provides illumination for the area array camera A2 (10) is e2, and the wavelength of the surface light source that provides illumination for the area array camera A3 (6) is e3 , the wavelength of the surface light source that provides illumination for the area array camera A4 (7) is e4, the wavelength of the line light source that provides illumination for the line array camera 5 is e5, and the wavelength ranges of e1 to e5 do not overlap. , A2 (10), A3 (6), A4 (7) and line array camera 5 front ends are respectively provided with the narrow band pass filter that wavelength is e1~e5, wherein e1=400nm, e2=500nm, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com