Cassava slicer capable of regulating size and shape of inlet

A slicing machine and cassava technology, applied in metal processing and other directions, can solve the problems of unfavorable packaging and finishing, the difference in thickness, shape and size of cassava chips, etc., and achieve the effect of accurate slicing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] as attached figure 1 to attach Figure 8 Shown:

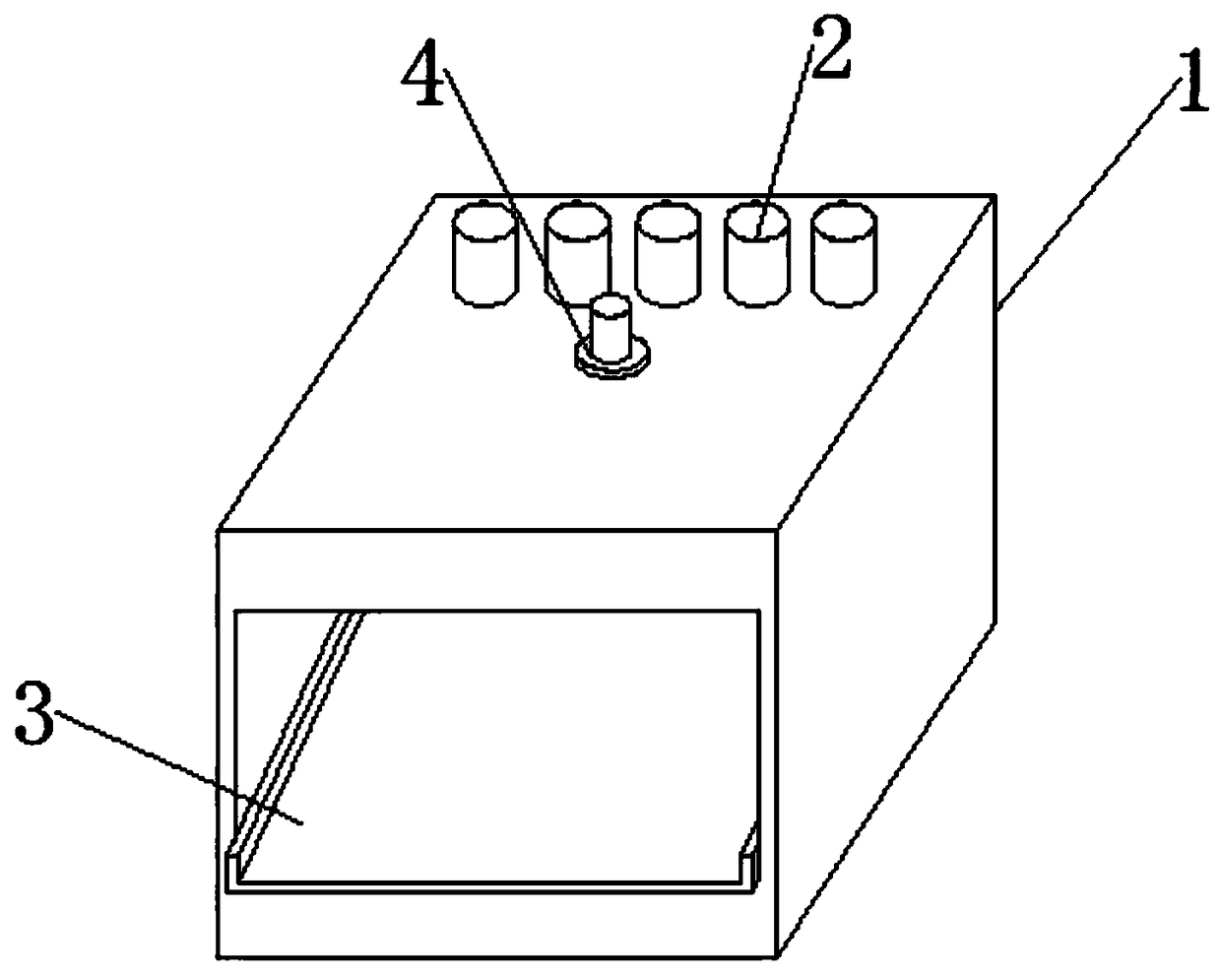

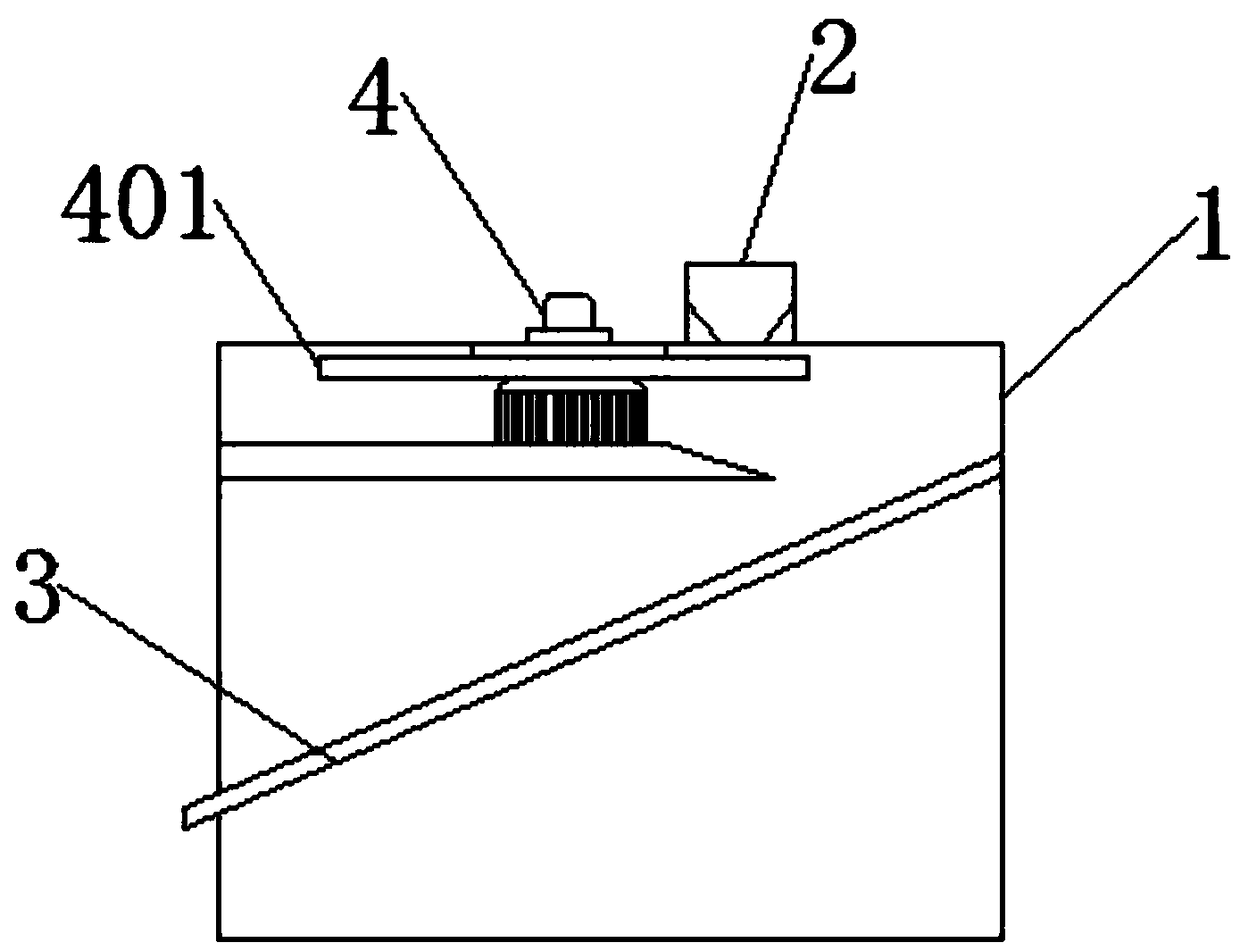

[0029] The invention provides a cassava slicer capable of adjusting the size and shape of the inlet, which includes a casing 1, an inlet 2, a discharge port 3 and a rotating shaft 4, the top opening of the casing 1 is provided with an inlet 2, and the front end of the casing 1 is fixedly connected with a discharge port 3. The top of the housing 1 is embedded with a rotating shaft 4, and the middle part of the rotating shaft 4 is connected with a cutting fan blade 401;

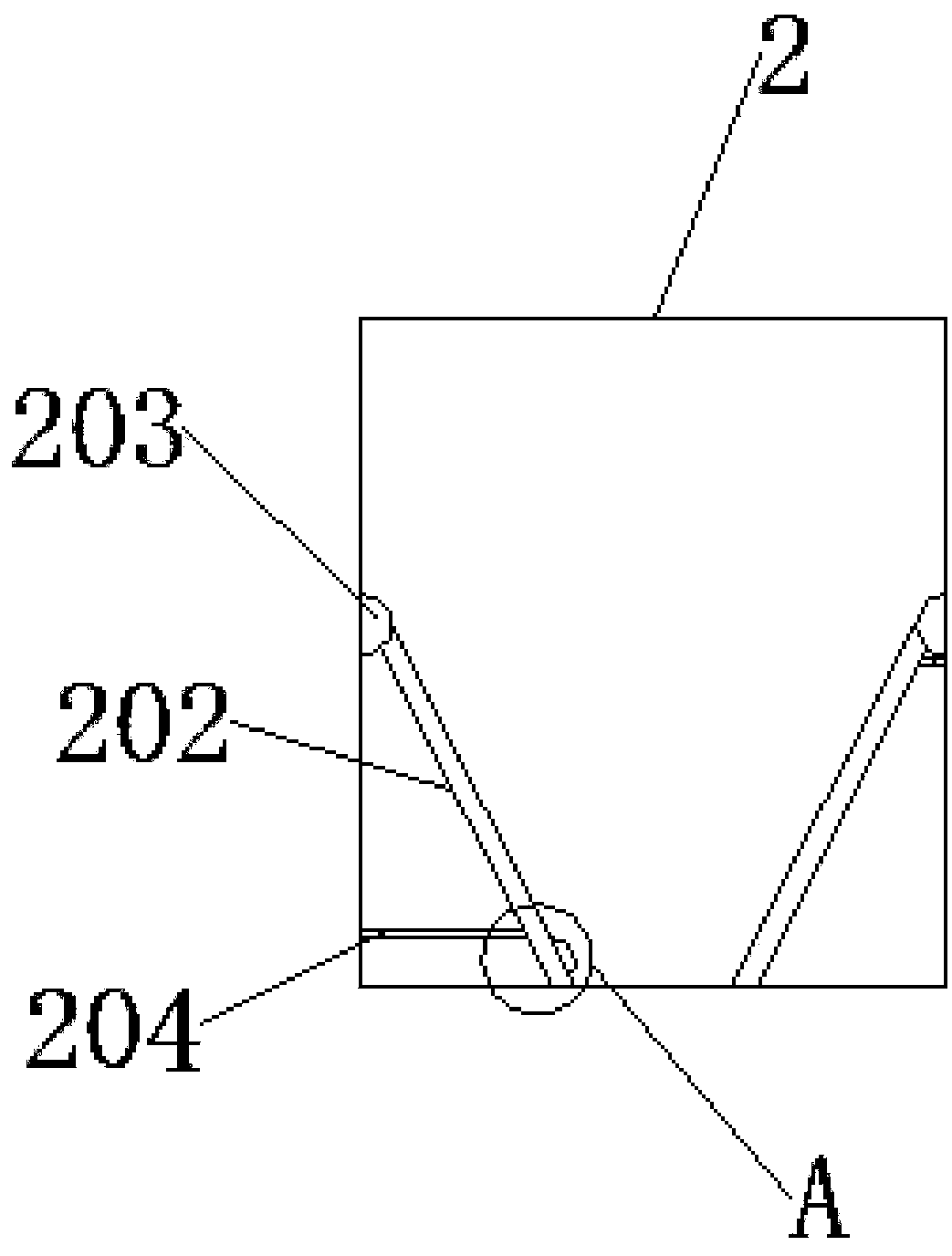

[0030] Inlet 2 includes swivel 201, socket rod 2011, expansion plate 202, pulley 2021, transmission gear 2022, fixed block 2023, collar 203, moving guide rod 204, return spring 2041 and sawtooth groove 2042, and swivel 201 is fixedly connected to In the middle of the inner wall of the entrance 2, the sleeve rod 2011 is fixedly connected to the middle of the swivel 201, the expansion plate 202 is embedded in the middle of the swivel 201 through the colla...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap