Tube head cutter for heat exchanger

A technology of cutters and heat exchangers, which is applied in the field of cutting tools and cutters, can solve the problems of large loss of grinding wheels, increased processing costs, and injury to people, and achieves the effects of fast and convenient replacement, improved work efficiency, and fast cutting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

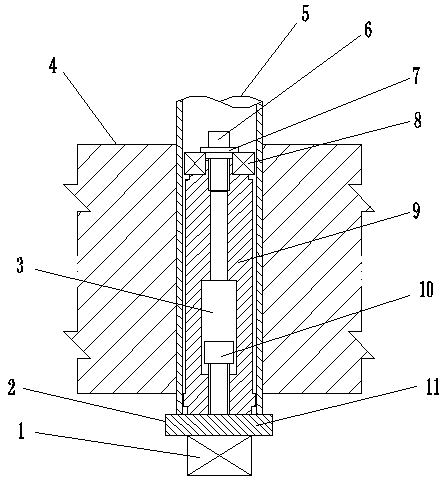

[0015] The technical solutions of the present invention will be further clearly and completely described below in conjunction with the accompanying drawings.

[0016] See attached figure 1 First, in the blade screw position 3 in the cutter body 9, use the blade fixing screw 10 to connect the blade 11 and the power connector 1, install the gasket 7 and the bearing 8 on the other end of the cutter body 9, and fix it with the bearing Bolt 6 is tightened. After the cutter body 9 is inserted into the heat exchange tube 5 mounted on the tube sheet 4, the power connector 1 drives the cutter to rotate through an external power source, so that the blade cutting edge 2 on the blade 11 extends out of excess to the heat exchange tube 5 The part is cut, and the alloy blade is used for cutting instead of grinding. The long cutter body 9 provided by the cutter is used to prevent the blade 11 from swinging, and the bearing 8 provided at the end of the cutter body 9 is used to reduce damage ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap