AOI detecting and discharging device

A technology for detecting components and material grasping, applied in the directions of transportation and packaging, conveyor objects, etc., can solve the problems of wrong detection, missed detection, restricting detection accuracy and detection efficiency, etc., to reduce uncertainty, improve production efficiency and product quality. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with specific drawings and embodiments.

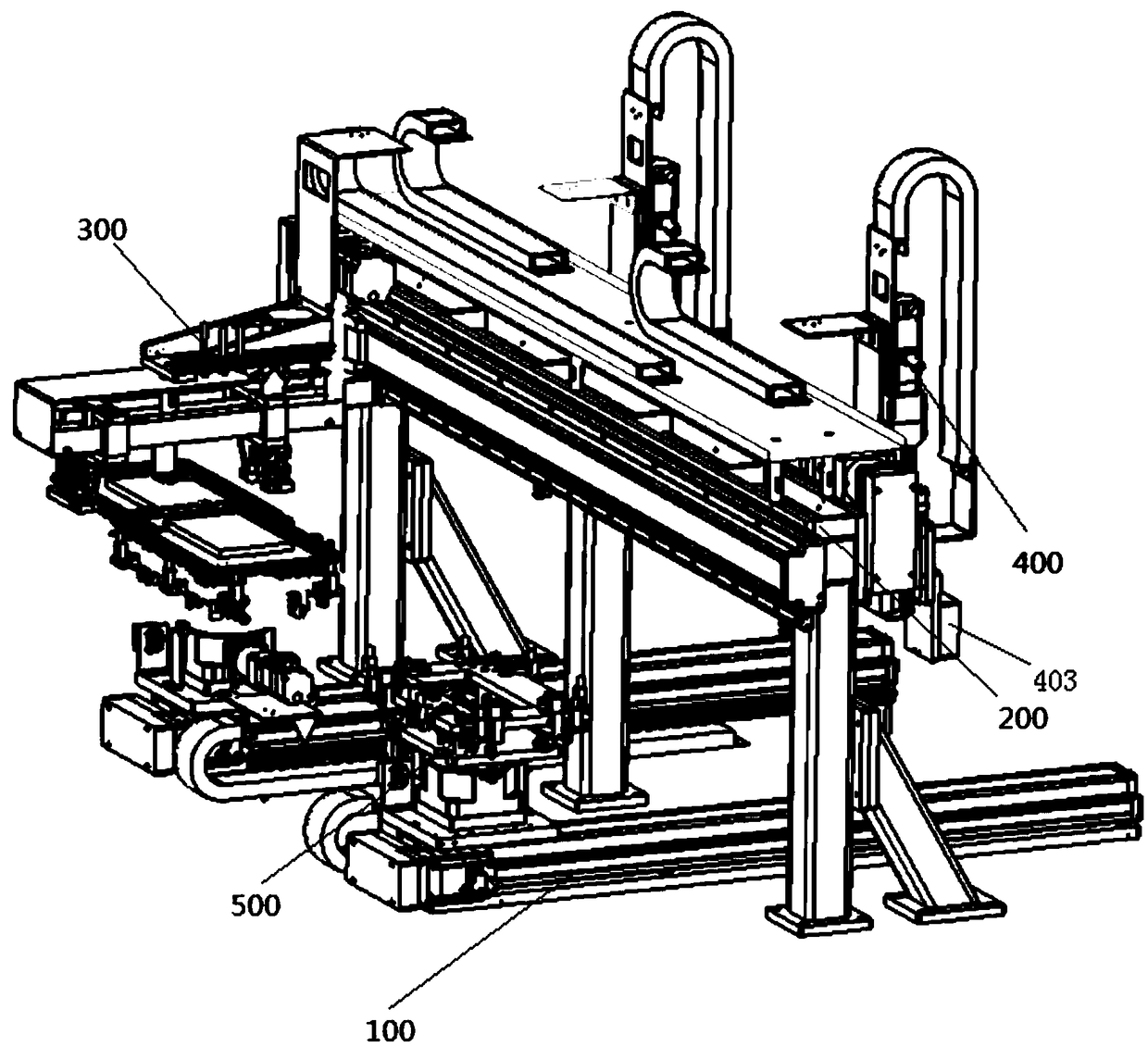

[0024] Such as Figure 1-7 Shown: an AOI detection and blanking device, the full name of AOI (Automated Optical Inspection) is automatic optical inspection, which is based on the optical principle to detect common defects encountered in welding production.

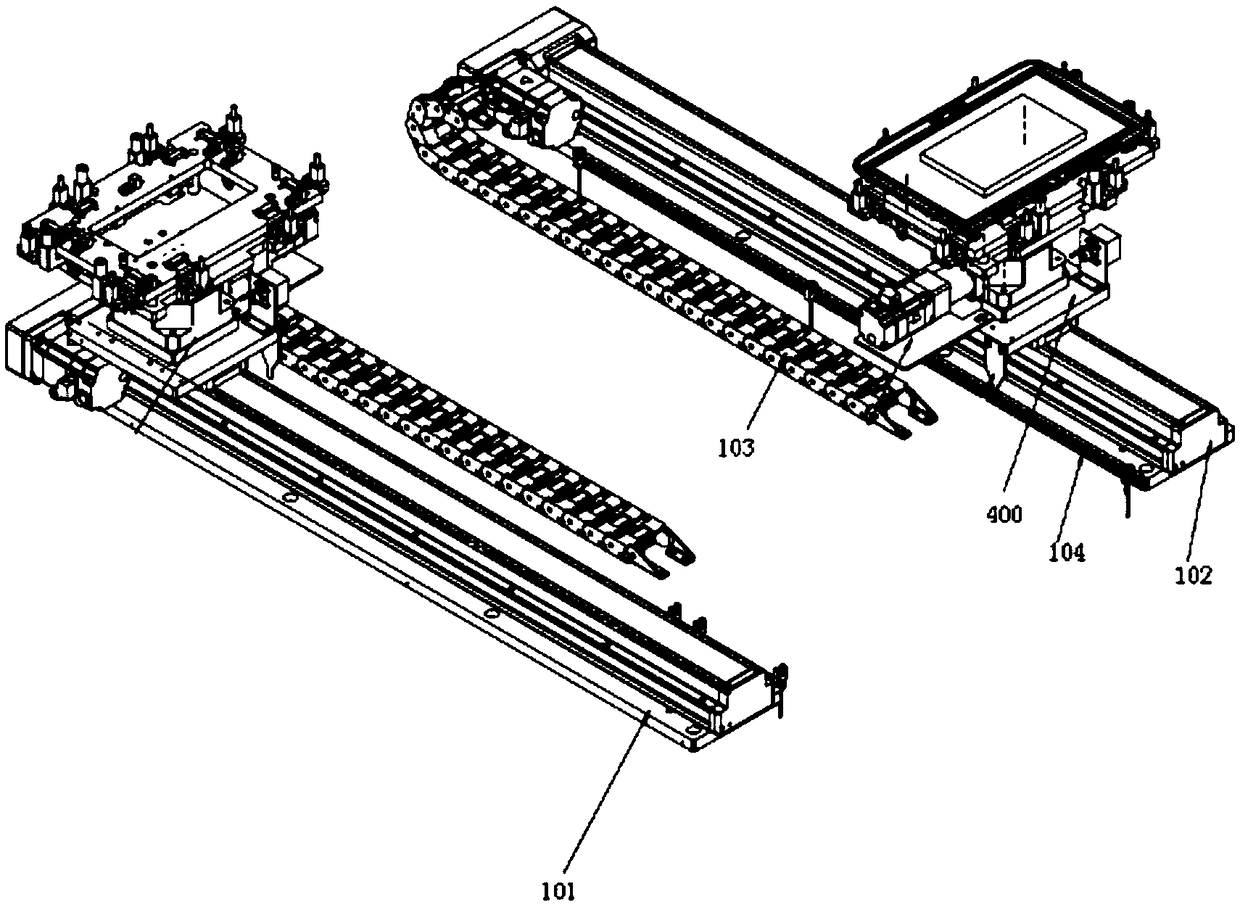

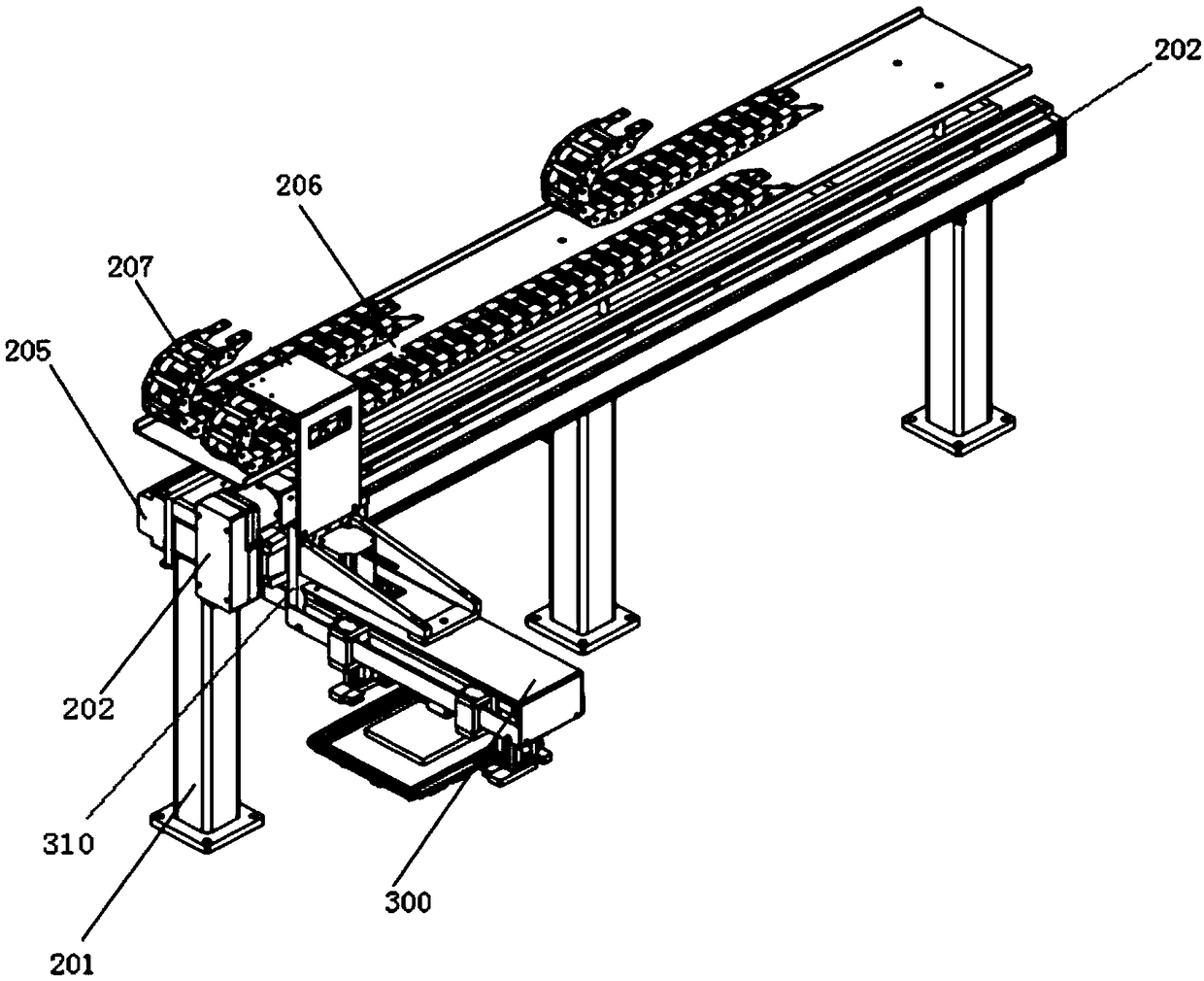

[0025] It is characterized in that it includes an X-axis detection component 100, a Y-axis detection component 200, a Z-axis component 400, a blanking gripper 300 and a θ-axis component 500;

[0026] The X-axis detection assembly 100 includes two X-axis bottom plates 101 arranged parallel to each other. The X-axis bottom plate is provided with an X-axis track 104 along the length direction. One end of the X-axis bottom plate is provided with an X-axis electric cylinder 102. 103 head end connection, the head end of the X-axis drag chain is wound and placed parallel to the X-axis bottom plate, and connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com