Device and method for simultaneously measuring multi coal seams gas pressure based on downward penetrating drilling

A gas pressure and pressure measurement device technology, applied in the direction of measurement, earthwork drilling, wellbore/well components, etc., to achieve the effects of simple and easy construction technology, saving measurement costs, and easy acquisition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

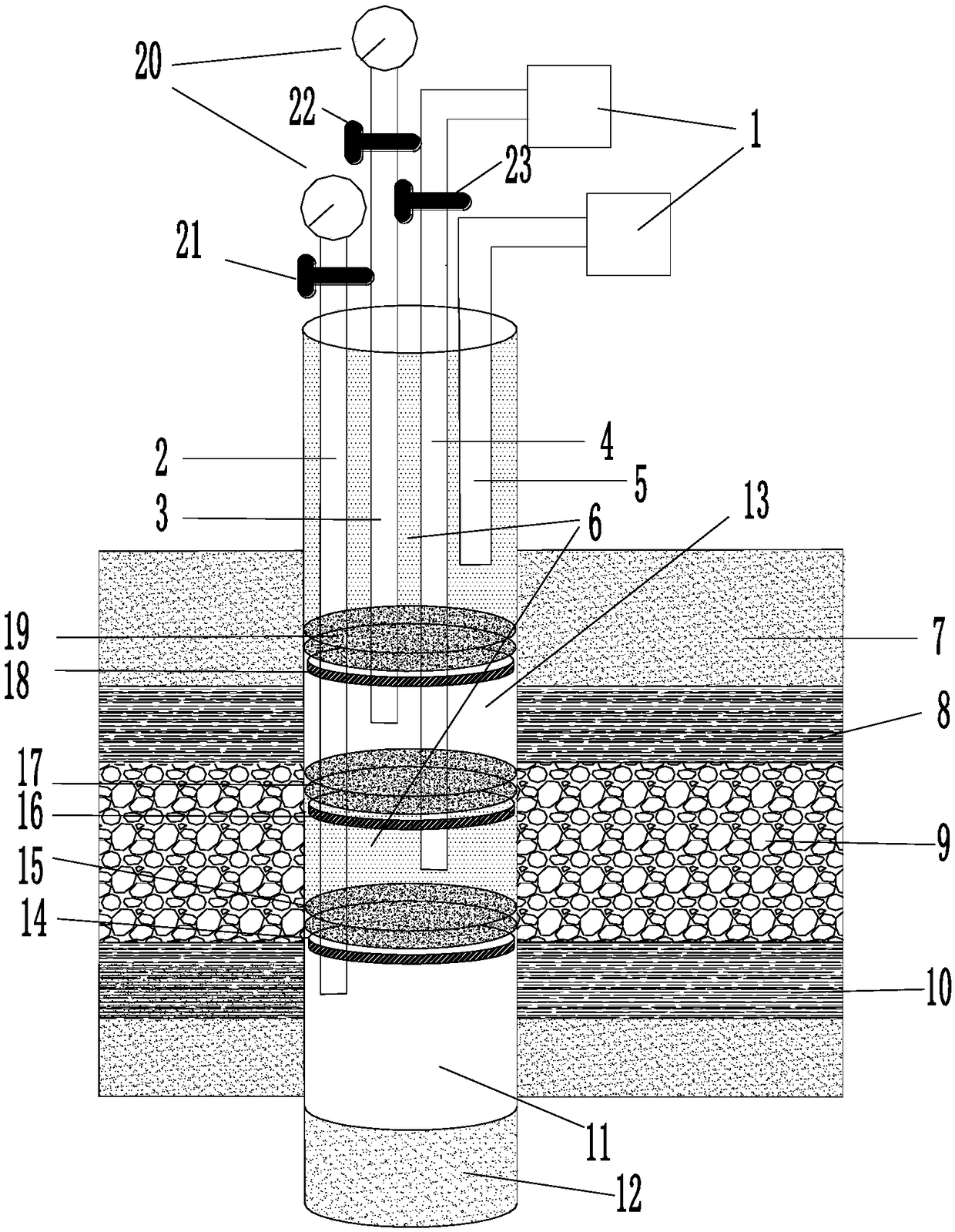

[0021] combined with figure 1 As shown, a device for simultaneously measuring the gas pressure of multiple coal seams based on downhole drilling includes a casing placed in the borehole and leading to multiple coal seams 8, 10 and rock formations 7, 9. The casing consists of piezometric tubes 2, 3. The grouting pipes 4 and 5 are composed of flanges 14, 16 and 18 corresponding to the positions of the top and bottom plates of the coal seams 8 and 10, and the pipes are respectively fixed with isolation plates adjacent to the flanges 14, 16 and 18. The bladders 15, 17, 19, and the isolation bladders 15, 17, 19 are used to isolate the air chambers 11, 13 and the cement mortar filling chamber 6, so as to prevent the cement mortar from flowing into the air chambers 11, 13. Each tube in the casing is divided into two types of purposes: grouting and pressure measurement. The space isolated between adjacent isolation bladders and the orifice are respectively connected through the grouti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com