Transverse and longitudinal load loading mechanism based on special simulation axle device

A technology of loading mechanism and simulated vehicle, which is applied in the direction of measuring device, testing of mechanical components, testing of machine/structural components, etc. It can solve problems such as inability to simulate the state of axle rotation from the axis, inability to carry out loading tests, and inability to load simultaneously

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be described in further detail below in conjunction with the accompanying drawings.

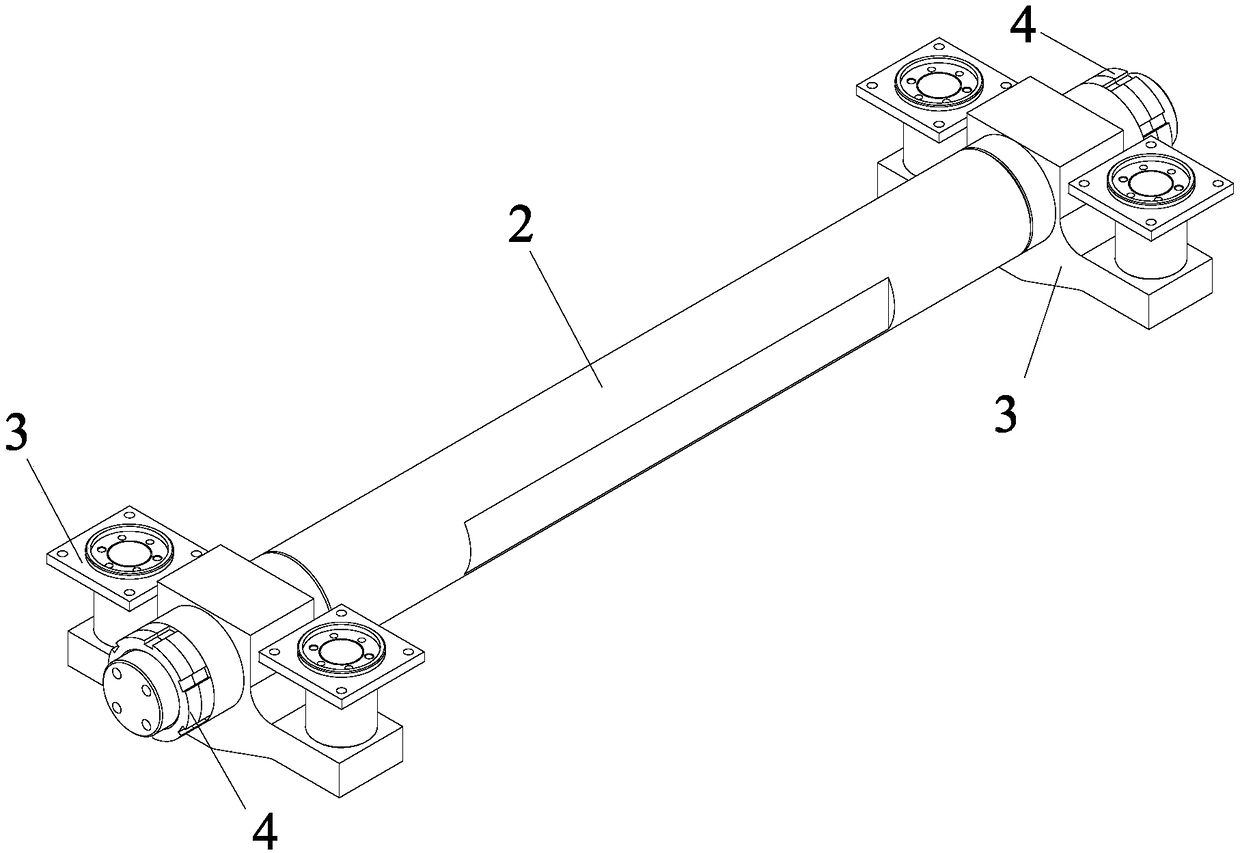

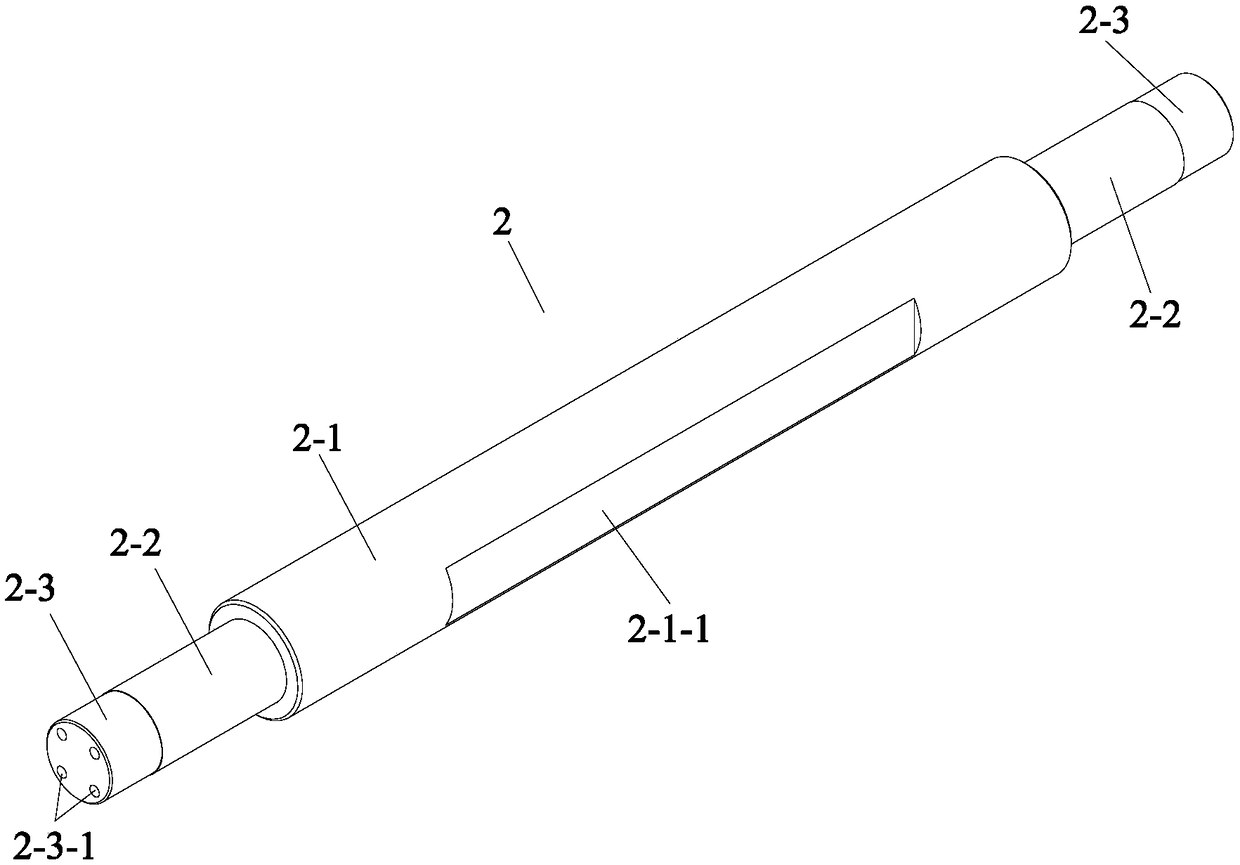

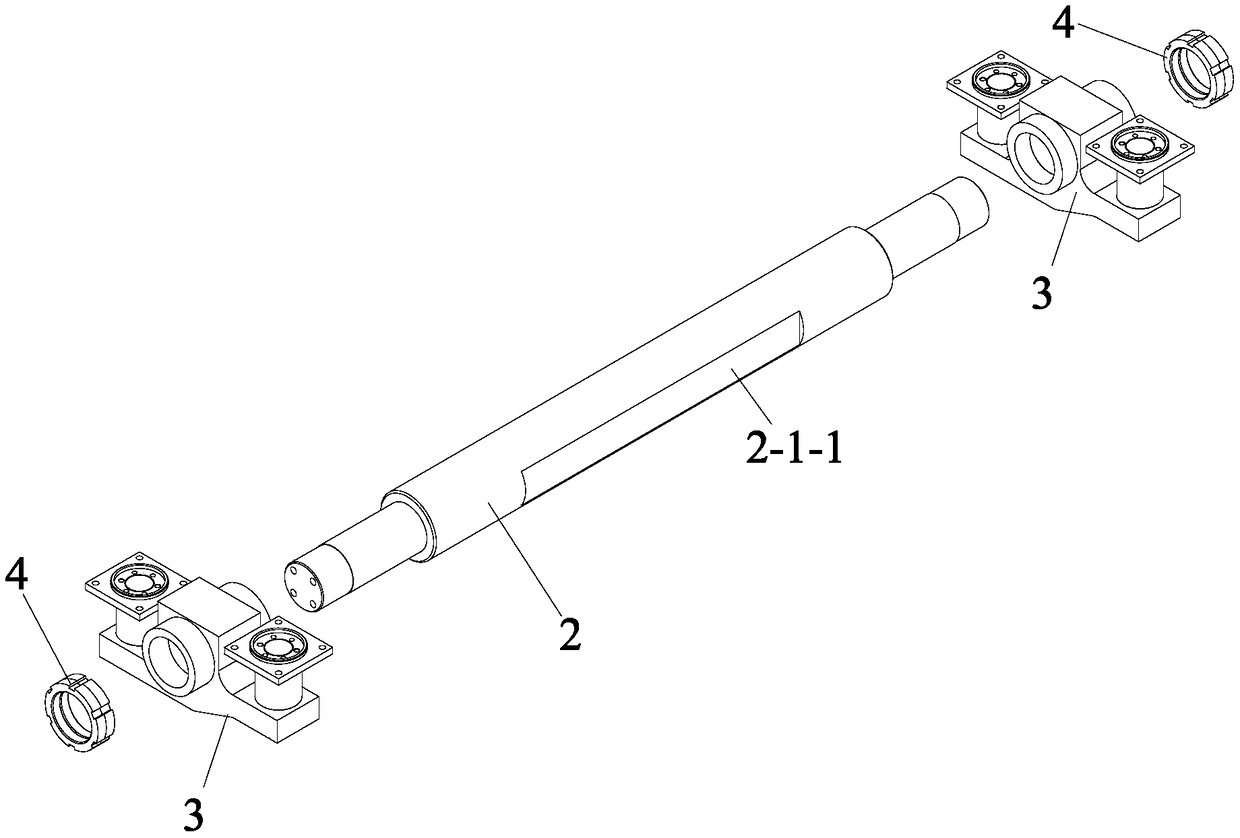

[0049] like Figure 9 to Figure 23 As shown, the transverse and longitudinal load loading mechanism based on the special simulated axle device of the present invention includes two sets of limit snap ring groups 4, axle box built-in axle 5, two conventional vertical loading cylinders C and two conventional transverse reaction cylinders. Force bar A, the load loading mechanism also includes two profiling simple herringbone axle box mechanisms 7, two horizontal and vertical two-way loading axle seat mechanisms 8, two lateral loading connecting blocks 9, two vertical loading connecting seats 10 and Two profiling axlebox spacing adjustment sleeves 11; two profiling simple herringbone axlebox mechanisms 7 are respectively coaxially connected with a corresponding new shaft diameter 5-2, and both of them are symmetrically attached to the new main shaft 5 -1 on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com