Detection and evaluation method for anti-adhesion property of tipping paper for cigarettes

A technology of cigarette tipping paper and evaluation method, which is applied in the direction of using mechanical devices, measuring devices, instruments, etc., can solve the problems of lack of detection means and corresponding evaluation methods, and no relevant reports on the anti-adhesion performance of cigarette tipping paper.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A method for detecting and evaluating the anti-blocking performance of tipping paper for cigarettes, comprising the following steps:

[0019] (1) Balance the tipping paper to be tested for 24 hours at a temperature of 25°C and a humidity of 65%;

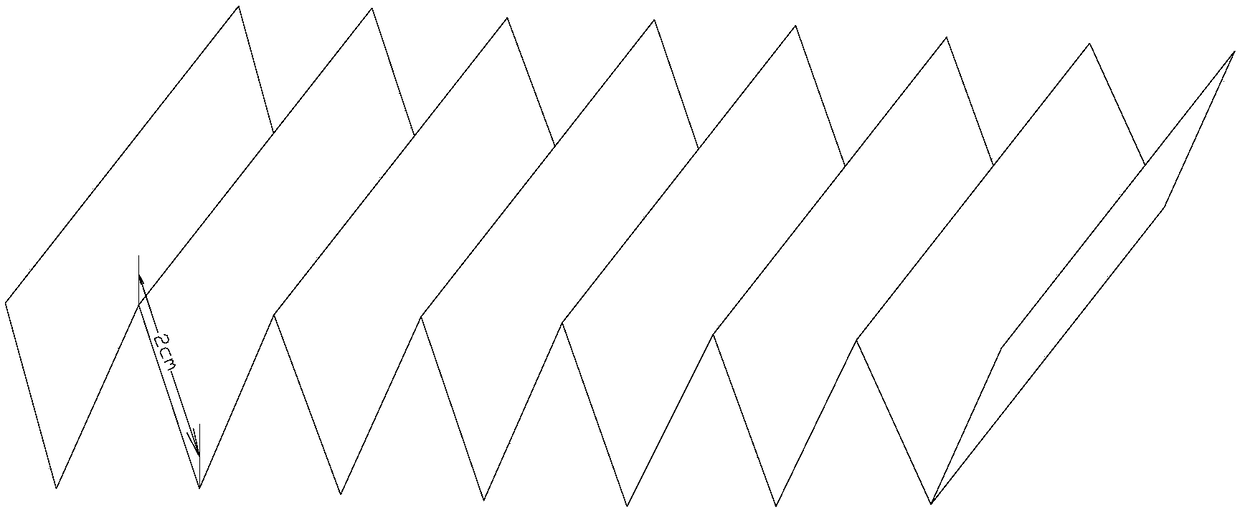

[0020] (2) Cut the 24 cm long tipping paper for pretreatment. Sampling should not take the outermost 3 circles of paper samples. figure 1 Fold back and forth in the same way, the number of folds is 11 times, and a total of 5 groups of samples are taken;

[0021] (3) Place the above-mentioned single paper pattern between two 100mm*100mm glass plates or smooth metal plates, place a 1000g weight on top, and place the whole in an oven that has been preheated for 30 minutes at a temperature of 100°C for 20 After 10 minutes, the samples were taken out and cooled naturally at room temperature;

[0022] (4) Fix the upper and lower sides of the pretreated sample to be tested on the base of the texture analyzer and the probe respectiv...

Embodiment 2

[0030] A method for detecting and evaluating the anti-blocking performance of tipping paper for cigarettes, comprising the following steps:

[0031] (1) Balance the tipping paper to be tested for 48 hours at a temperature of 30°C and a humidity of 60%;

[0032] (2) Cut the 24 cm long tipping paper for pretreatment. Sampling should not take the outermost 3 circles of paper samples. figure 1 Fold back and forth in the same way, the number of folds is 9 times, and a total of 5 groups of samples are taken;

[0033] (3) Place the above-mentioned single paper pattern between two 100mm*100mm glass plates or smooth metal plates, place a 1000g weight on top, and place the whole in an oven that has been preheated for 30 minutes at a temperature of 105°C. After 10 minutes, the samples were taken out and cooled naturally at room temperature;

[0034] (4) Fix the upper and lower sides of the pretreated sample to be tested on the base of the texture analyzer and the probe respectively wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com