Stationary blow molding machine and method for forming plastic parisons

一种塑料型坯、吹塑模具的技术,应用在生产塑料瓶的设备领域

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

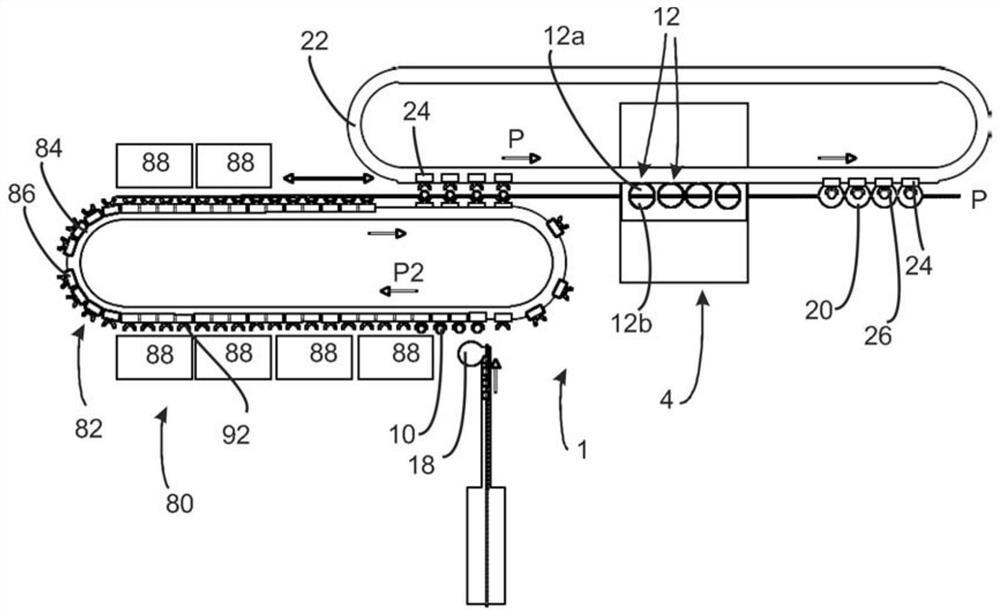

[0085] FIG. 1 shows a schematic diagram of an apparatus 1 according to the invention for processing containers. In this case, the plastic parisons 10 are first conveyed to a heating device, which is generally designated by the reference numeral 80 . Here, the heating device has a plurality of fixedly arranged heating elements or heating elements 88 , past which the plastic parisons are transported along the transport path P2 . For this purpose, the heating device has a circumferential carrier 84 on which a plurality of transport elements 86 are arranged such that they can be transported independently of one another. Reference numeral 82 designates the entire transport device. Reference numeral 18 designates a conveying device, for example a conveying star wheel for conveying the plastic parisons to the heating device 80 . Reference numeral 92 designates a holding device for holding plastic parisons.

[0086] After the plastic parisons 10 have passed the heating device 80 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com