Tire and method for manufacturing tire

A technology for tires and solid tires, applied to tire treads/tread patterns, tire parts, tires, etc., can solve the problems of charge flow obstruction, material waste, harmfulness, etc., and achieve the effect of improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

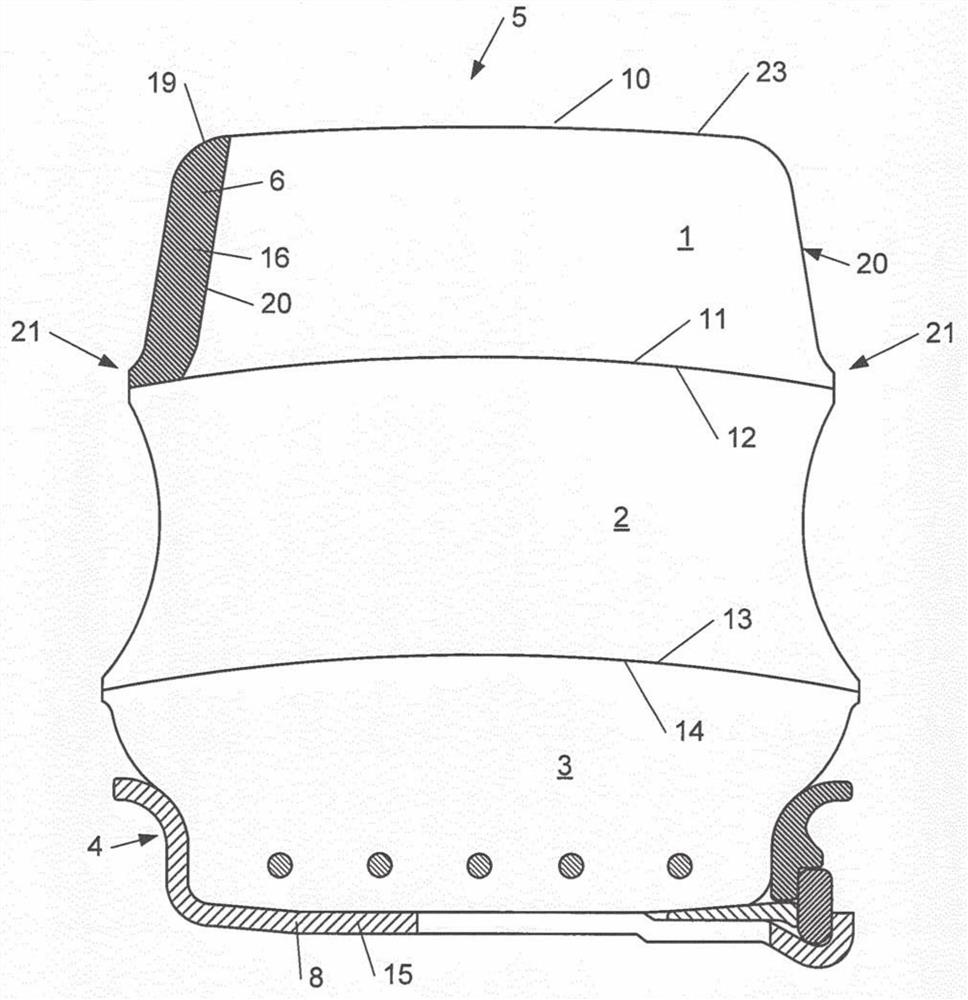

[0148] The invention relates to a method for the manufacture of a tire 5 for a wheel 4 of a vehicle comprising an electrically conductive means 15, such as figure 1 shown in . Especially when the tires are solid tyres, the wheels 4 are suitable for use with any vehicle known to those skilled in the art, such as fork lift trucks.

[0149] According to this invention, there is provided a method for manufacturing a tire 5 of a vehicle wheel 4 comprising electrically conductive means 15 , the tire 5 comprising a tread surface 23 delimited by two opposite sidewalls 21 . The method comprises the sequential steps of:

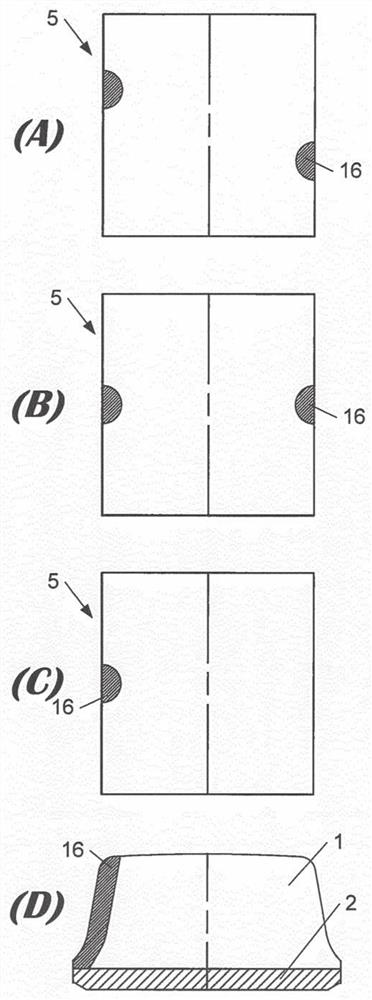

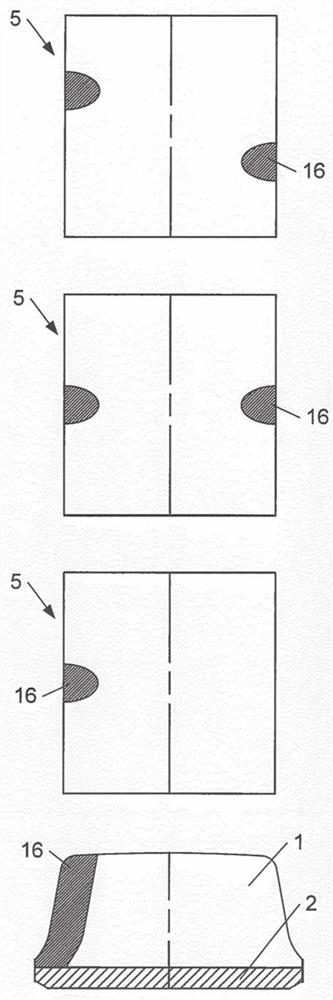

[0150] - manufacture of a spare tire comprising a first layer 1 extending in the circumferential direction of the tyre. The first layer 1 comprises an outer circumferential surface 10 and an inner circumferential surface 11 interconnected by opposing first layer side walls 20 which together delimit the first layer 1 . The first layer is made of a first material comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com