Turnover type automatic dispensing machine

An automatic point and flip technology, which is applied in the pretreatment surface, the device for applying liquid to the surface, the coating, etc., can solve problems such as low production efficiency, improve production efficiency, and reduce the process of machine adjustment and adjustment. time, the effect of reducing the risk of collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

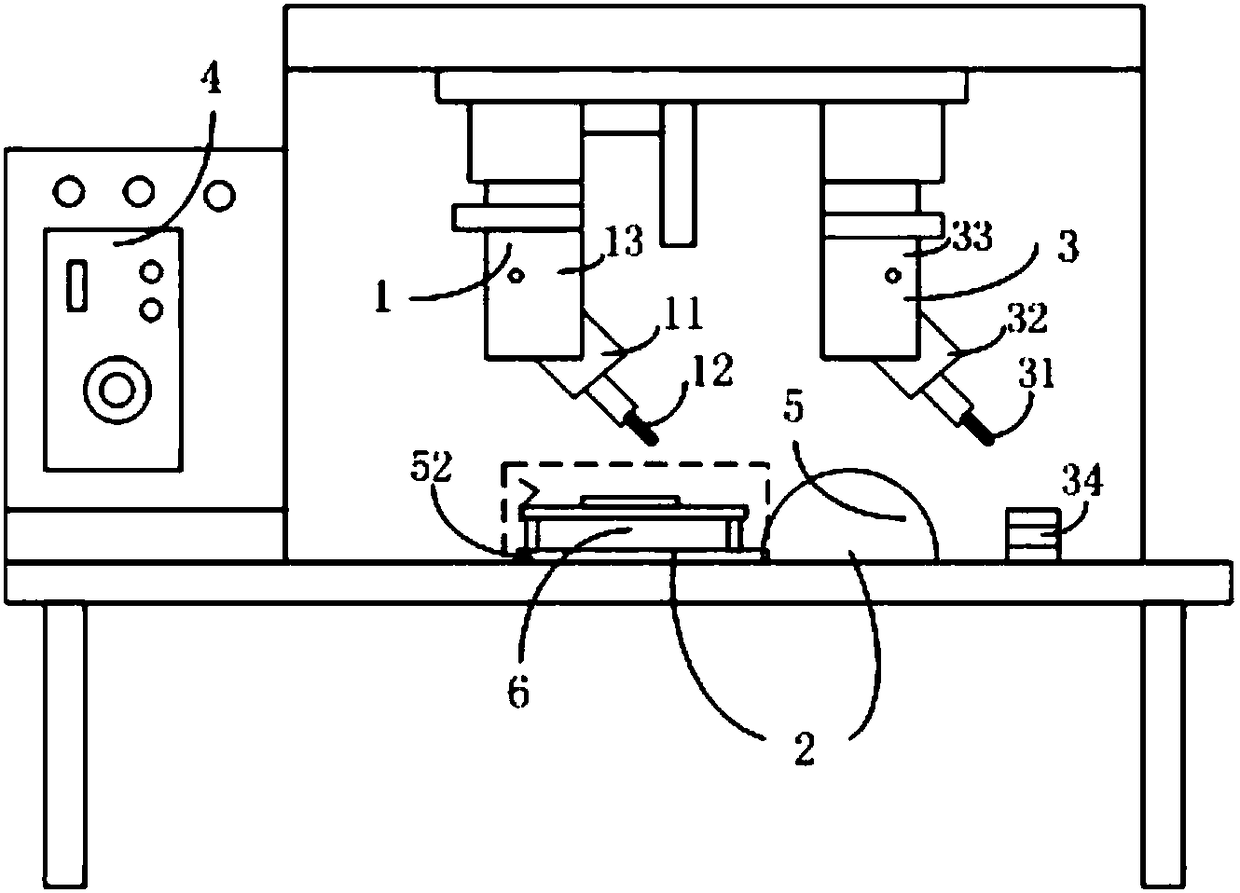

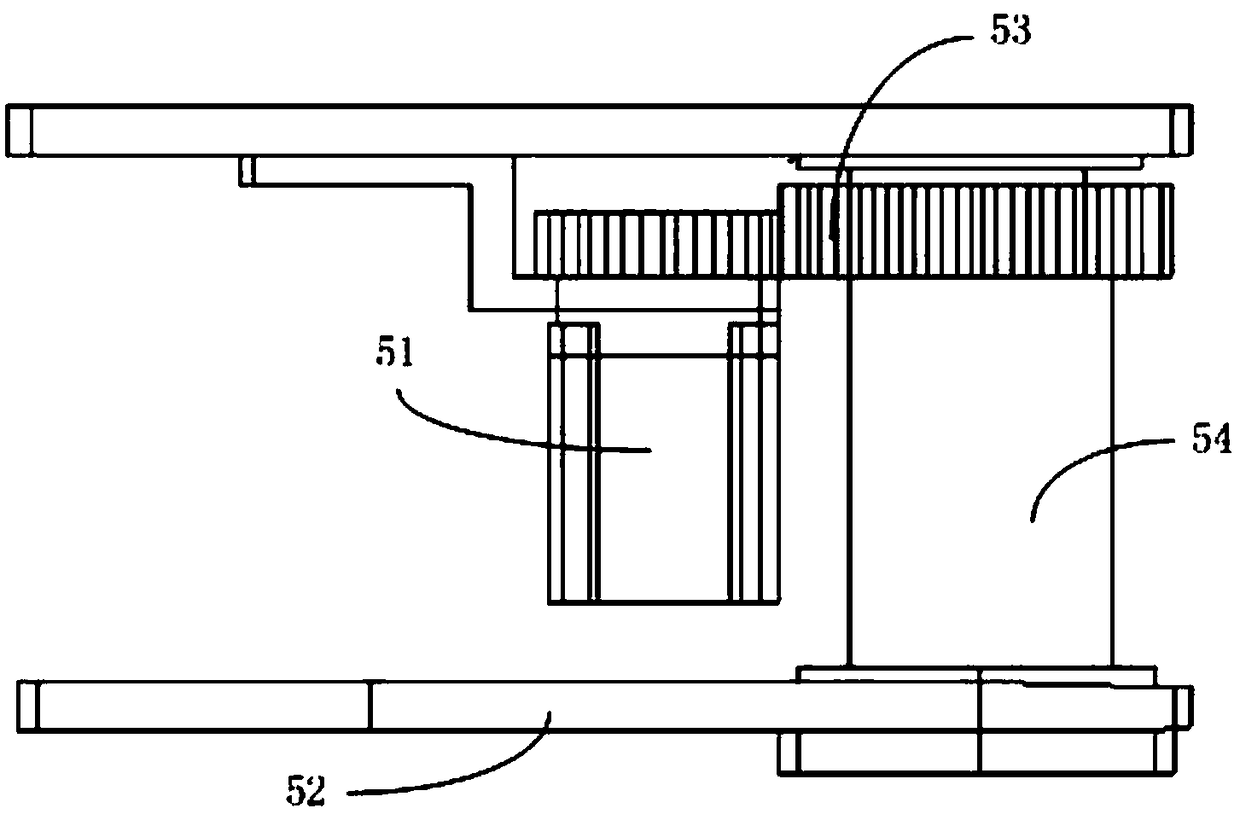

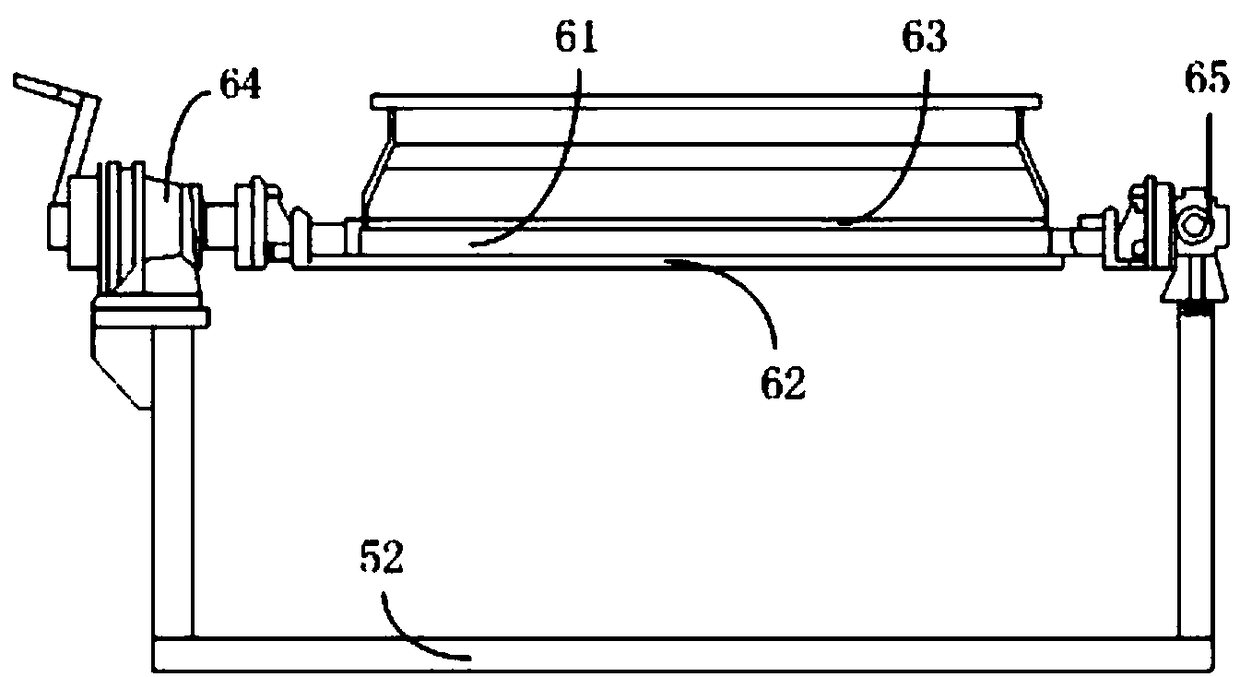

[0026] like figure 1 , as shown in 2 and 3, a reversible automatic dispensing machine includes a first dispensing mechanism 1, a reversing mechanism 2, a second dispensing mechanism 3, and a control module 4, and the reversing mechanism 2 includes a first reversing device 5 And the second flipper 6, the first flipper 5 includes a drive motor 51, a bracket 52, a gear 53 and a rotating track 54, the output shaft of the drive motor 51 is meshed with a gear 53 through a gear, and the gear 53 covers Connected on the rotating track 54, the rotating track 54 is connected with a bracket 52, the second flipper 6 is connected with the bracket 52 of the first flipper 5, and the second flipper 6 includes a turning shaft 61 and a rotating plate 62 , the rotating plate 62 is provided with a pressing plate 63 for positioning, one end of the turning shaft 61 is provided with a reducer 64 with a locking device, and the other end is connected with the support seat 65, and the rotating plate 62 ...

Embodiment 2

[0038] like figure 1 , as shown in 2 and 3, a reversible automatic dispensing machine includes a first dispensing mechanism 1, a reversing mechanism 2, a second dispensing mechanism 3, and a control module 4, and the reversing mechanism 2 includes a first reversing device 5 And the second flipper 6, the first flipper 5 includes a drive motor 51, a bracket 52, a gear 53 and a rotating track 54, the output shaft of the drive motor 51 is meshed with a gear 53 through a gear, and the gear 53 covers Connected on the rotating track 54, the rotating track 54 is connected with a bracket 52, the second flipper 6 is connected with the bracket 52 of the first flipper 5, and the second flipper 6 includes a turning shaft 61 and a rotating plate 62 , the rotating plate 62 is provided with a pressing plate 63 for positioning, one end of the turning shaft 61 is provided with a reducer 64 with a locking device, and the other end is connected with the support seat 65, and the rotating plate 62 ...

Embodiment 3

[0045] like figure 1 , as shown in 2 and 3, a reversible automatic dispensing machine includes a first dispensing mechanism 1, a reversing mechanism 2, a second dispensing mechanism 3, and a control module 4, and the reversing mechanism 2 includes a first reversing device 5 And the second flipper 6, the first flipper 5 includes a drive motor 51, a bracket 52, a gear 53 and a rotating track 54, the output shaft of the drive motor 51 is meshed with a gear 53 through a gear, and the gear 53 covers Connected on the rotating track 54, the rotating track 54 is connected with a bracket 52, the second flipper 6 is connected with the bracket 52 of the first flipper 5, and the second flipper 6 includes a turning shaft 61 and a rotating plate 62 , the rotating plate 62 is provided with a pressing plate 63 for positioning, one end of the turning shaft 61 is provided with a reducer 64 with a locking device, and the other end is connected with the support seat 65, and the rotating plate 62 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com