Welding conveying production line based on connecting transportation

A production line, sliding connection technology, applied in metal processing equipment, feeding devices, manufacturing tools, etc., can solve problems such as high cost and low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

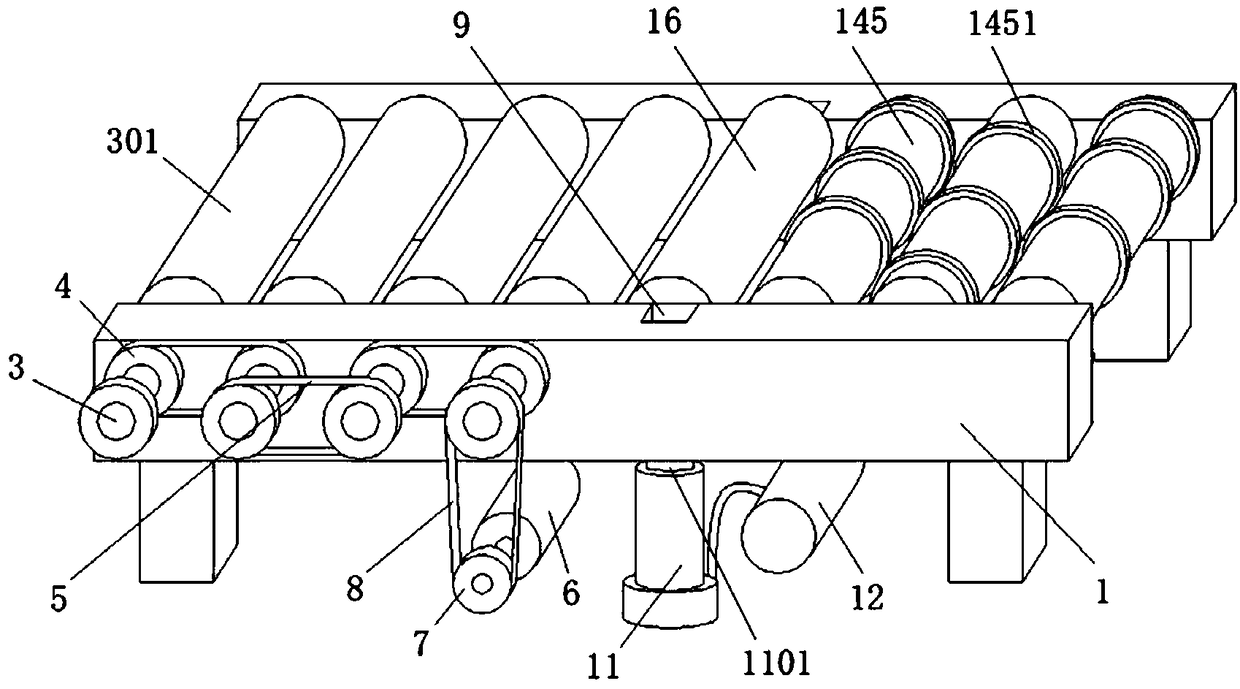

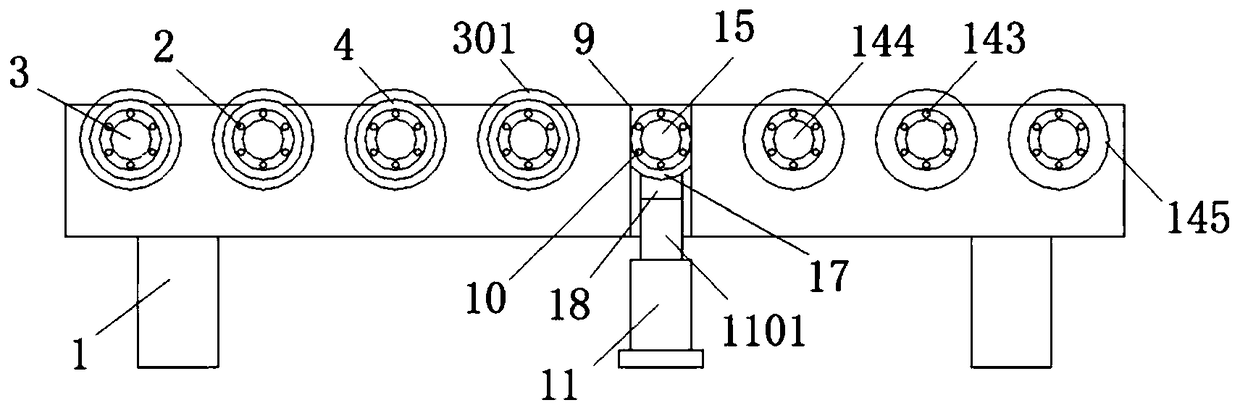

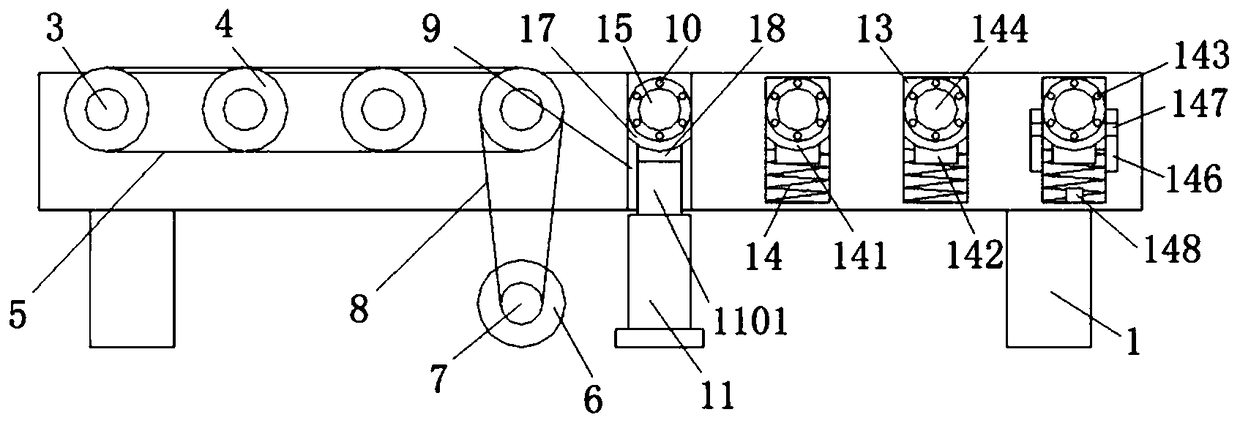

[0029] The following is attached Figure 1-7 The present invention is described in further detail.

[0030] A welding conveying line based on connection transportation, such as Figure 1-2 As shown, including the mounting frame 1, the surface of the mounting frame 1 is fixedly installed with a fixed bearing 2, a plurality of fixed bearings 2 are evenly distributed on the surface of the mounting frame 1, the inner ring of the fixed bearing 2 is fixedly connected with a power shaft 3, and the power shaft 3 The surface of the power shaft 3 is fixedly connected with a power roller 301, one end of the power shaft 3 runs through and extends to the surface of the installation frame 1, and one end of the power shaft 3 is fixedly connected with a pulley group 4, and a plurality of pulley groups 4 are connected through transmission belts 5. There is a power motor 6 under the frame 1. The model of the power motor 6 includes YE2-80M1-2. The output shaft of the power motor 6 is fixedly co...

Embodiment 1

[0036] A welding conveying line based on connection transportation, such as Figure 1-2 As shown, including the mounting frame 1, the surface of the mounting frame 1 is fixedly installed with a fixed bearing 2, a plurality of fixed bearings 2 are evenly distributed on the surface of the mounting frame 1, the inner ring of the fixed bearing 2 is fixedly connected with a power shaft 3, and the power shaft 3 The surface of the power shaft 3 is fixedly connected with a power roller 301, one end of the power shaft 3 runs through and extends to the surface of the installation frame 1, and one end of the power shaft 3 is fixedly connected with a pulley group 4, and a plurality of pulley groups 4 are connected through transmission belts 5. There is a power motor 6 under the frame 1. The model of the power motor 6 includes YE2-80M1-2. The output shaft of the power motor 6 is fixedly connected with the driving wheel 7 through a coupling, and the driving wheel 7 is connected to one of the...

Embodiment 2

[0042] A welding conveying line based on connection transportation, such as Figure 1-2As shown, including the mounting frame 1, the surface of the mounting frame 1 is fixedly installed with a fixed bearing 2, a plurality of fixed bearings 2 are evenly distributed on the surface of the mounting frame 1, the inner ring of the fixed bearing 2 is fixedly connected with a power shaft 3, and the power shaft 3 The surface of the power shaft 3 is fixedly connected with a power roller 301, one end of the power shaft 3 runs through and extends to the surface of the installation frame 1, and one end of the power shaft 3 is fixedly connected with a pulley group 4, and a plurality of pulley groups 4 are connected through transmission belts 5. There is a power motor 6 under the frame 1. The model of the power motor 6 includes YE2-80M1-2. The output shaft of the power motor 6 is fixedly connected with the driving wheel 7 through a coupling, and the driving wheel 7 is connected to one of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com