Capacitor welding and clamping apparatus and welding signal processing method

A signal processing and welding device technology, applied in capacitors, auxiliary devices, welding equipment, etc., can solve problems such as high cost, welding needle system interference, inaccurate control, etc., to reduce labor costs, reduce manual operations, and improve work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

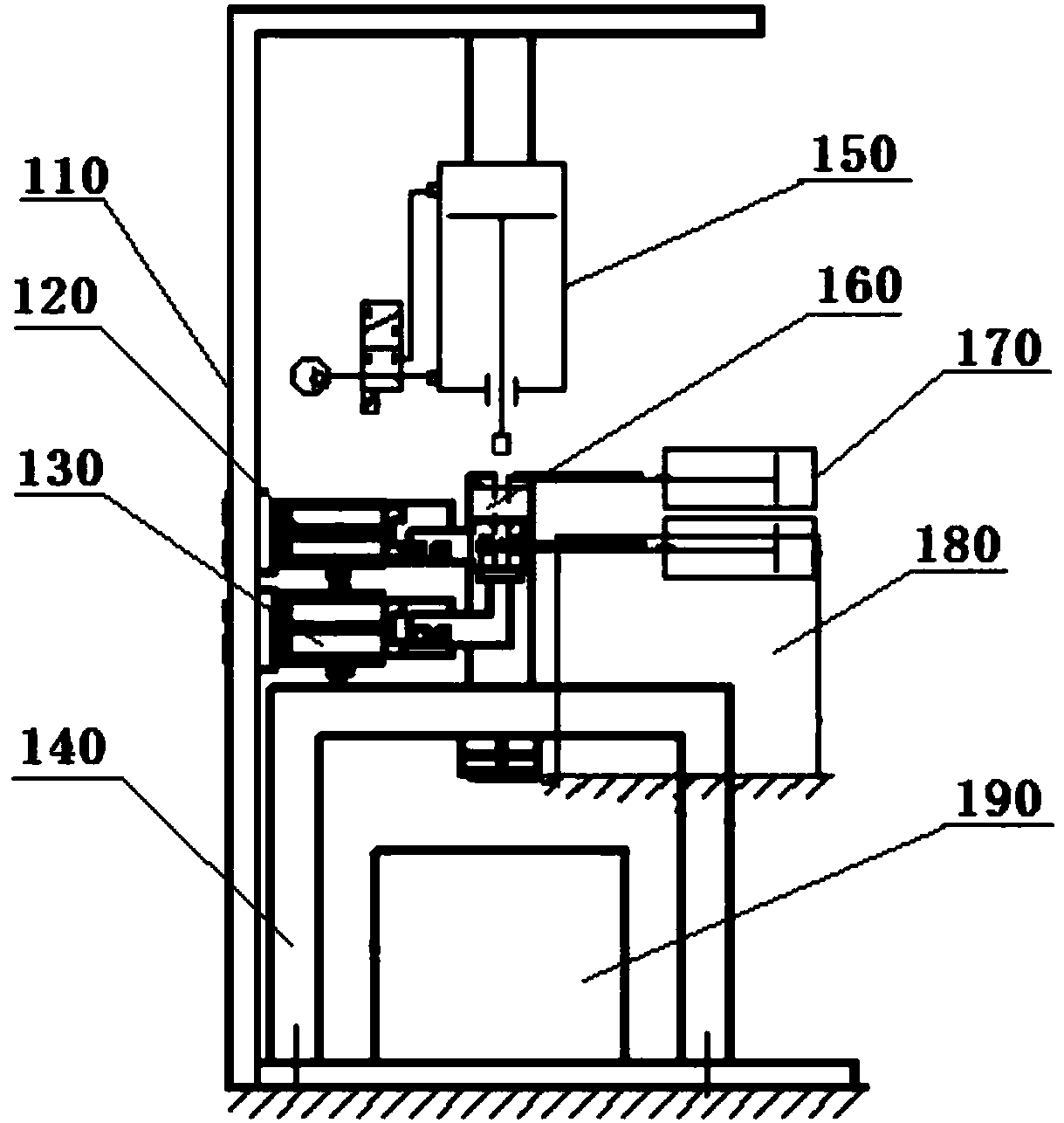

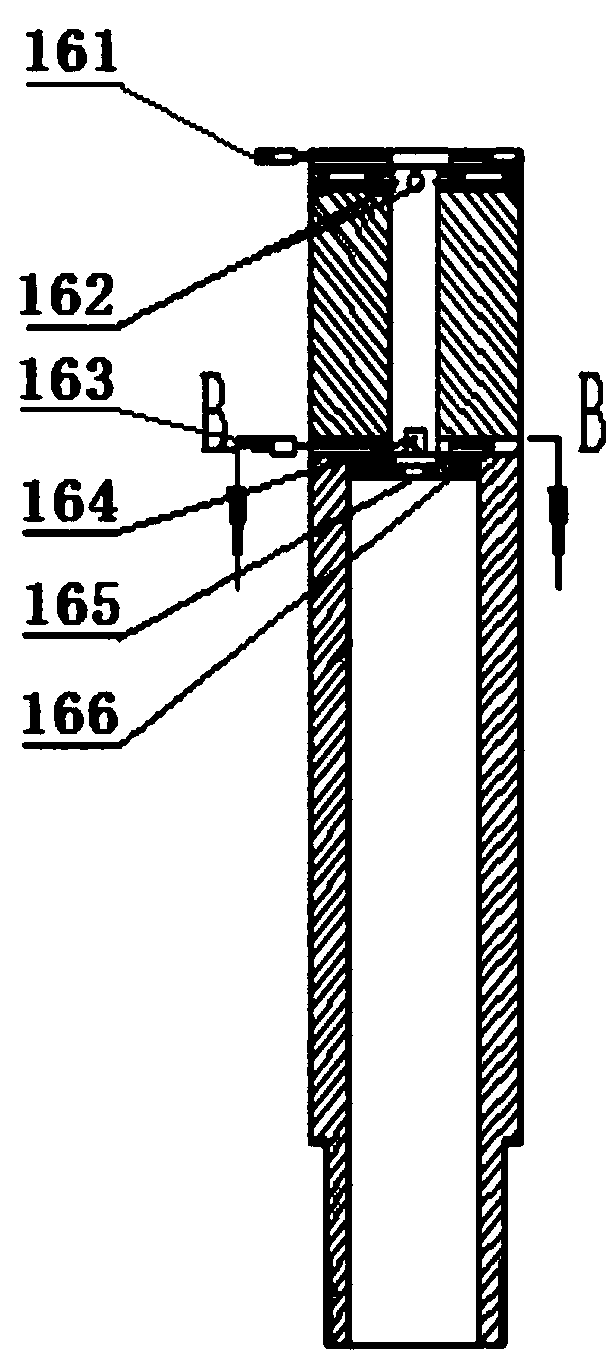

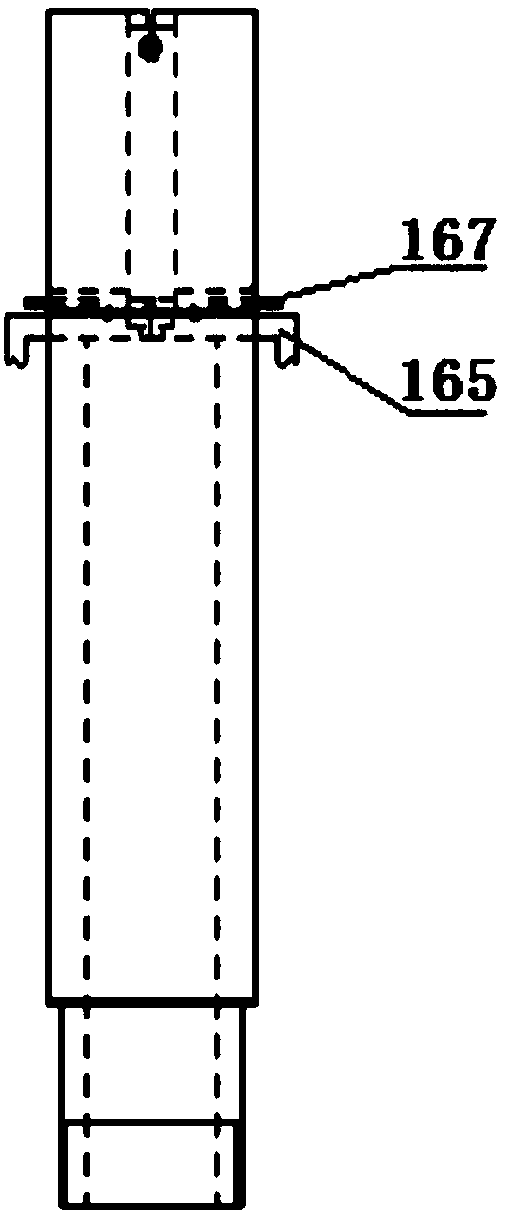

[0041] Such as figure 1 As shown, the present invention provides a capacitor welding clamping device, including: a load-bearing frame 110, a push-down mechanism 150, a welding device 120, a clamping device 130, a support shell 140, a receiving box 190, a set-up mold 160, Capacitor monomer feeding device 170 and assembly feeding device 180 .

[0042] The load-bearing frame 110 includes an upper horizontal plate, vertically connected columns and a lower horizontal plate; the load-bearing frame 110 is a cuboid structure with an opening on one side; the push-down mechanism 150 is arranged inside the load-bearing frame, and one end is connected to the upper horizontal plate The bottom of the push-down mechanism 150 is provided with a push-down block, which is driven by the push-d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com