Machine oil filler cap machining equipment

A technology for oil filler caps and processing equipment, applied in metal processing equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of reduced production efficiency, long time, troublesome operation, etc., to achieve improved efficiency, simple operation, and guaranteed processing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

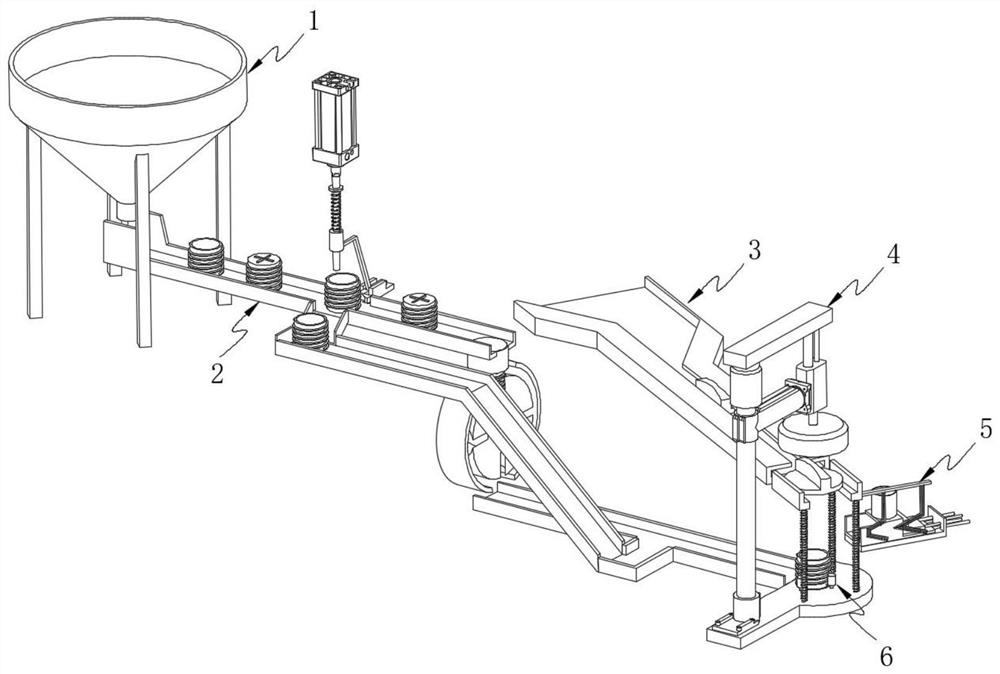

[0047] like figure 1 As shown, the present invention provides a fuel filler cap processing equipment, comprising: a vibrating funnel 1;

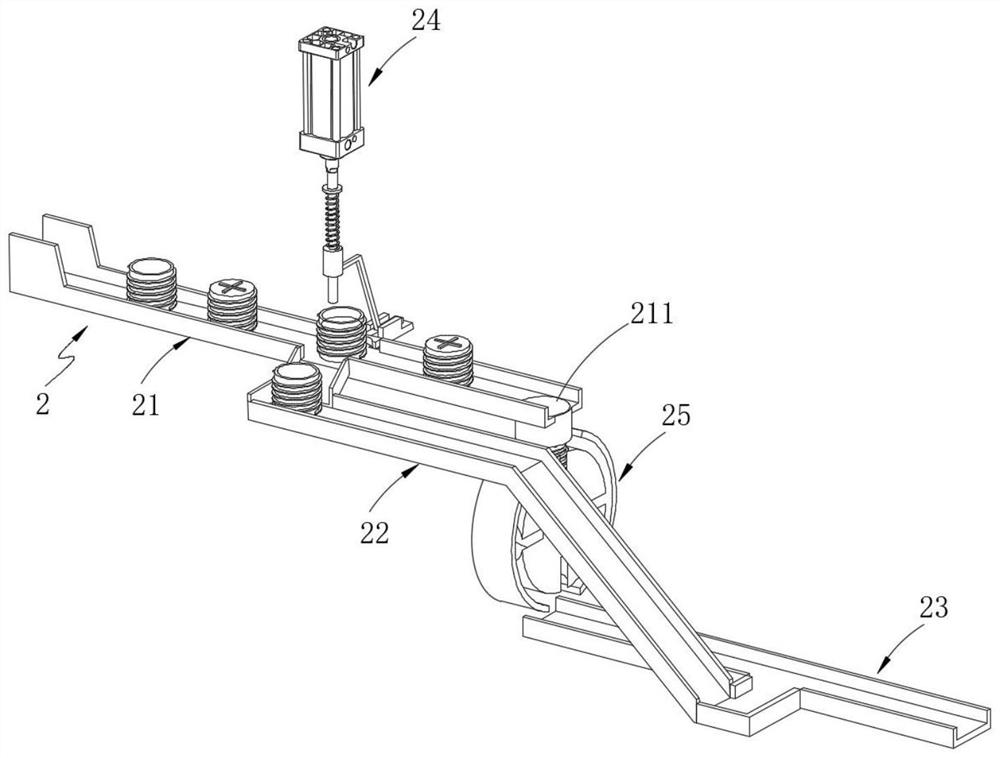

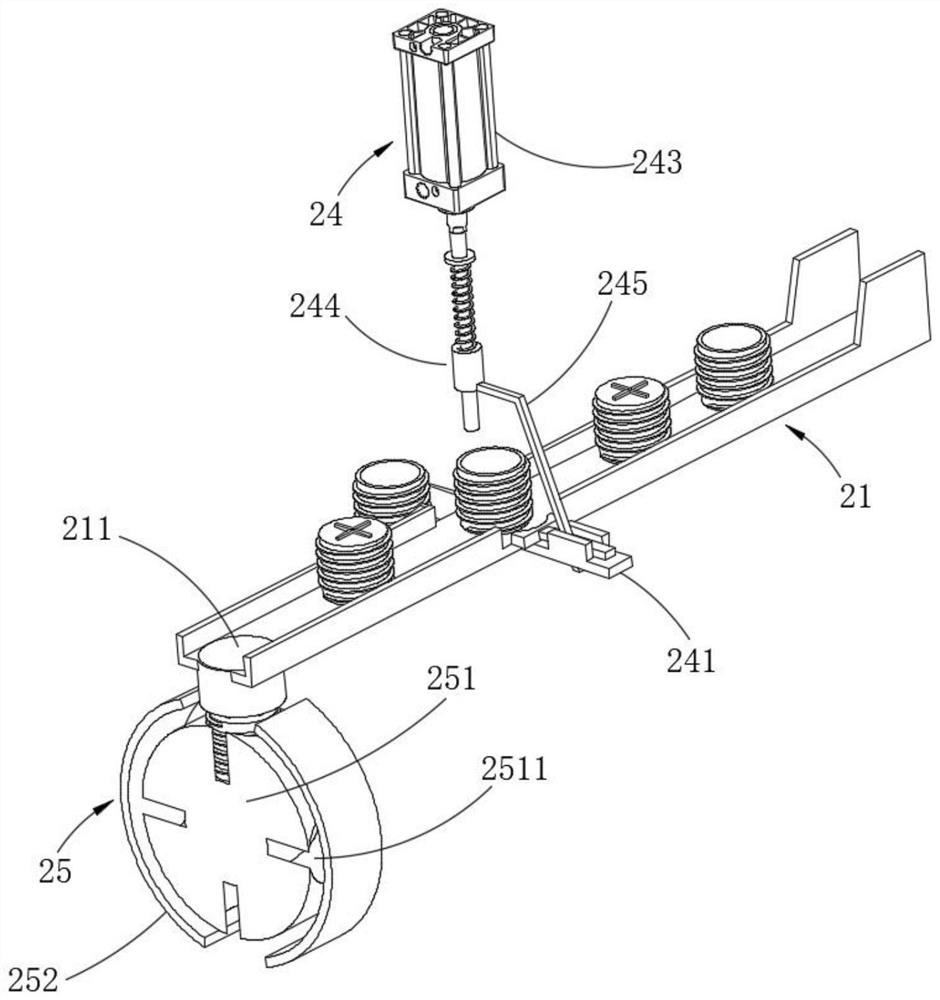

[0048] The first transmission part 2, the first transmission part 2 is arranged on one side of the vibration funnel 1 to transmit the lower casing;

[0049] The second transmission part 3, the second transmission part 3 is arranged on one side of the first transmission part 2 to transmit the upper casing;

[0050] The spin welding processing part 4, the spin welding processing part 4 is arranged at the output end of the first transmission part 2 to assemble the lower casing and the upper casing together by a rotating welding process;

[0051] Pushing member 5, the pushing member 5 is arranged on one side of the second transmission member 3 to push the sponge ball into the lower casing.

[0052] In the present invention, the lower casing is put into the vibrating funnel 1, the first transmission part 2 transmits the lower casing, the secon...

Embodiment 2

[0087] like Figure 10 As shown, the same or corresponding components as those in the first embodiment are given the corresponding reference numerals as in the first embodiment. For the sake of brevity, only the points of difference from the first embodiment are described below. The difference between the second embodiment and the first embodiment is:

[0088] This embodiment also includes a positioning member 6, which is arranged on the spin welding processing member 4 to position the lower casing.

[0089] further, as Figure 10 and Figure 11 As shown, the positioning member 6 includes: a cross groove 421, which is opened on the worktable 42; a transmission shaft 61, a plurality of sets of transmission shafts 61 are arranged beside the cross groove 421 to rotate the lower casing; a connecting rod 62, a connecting rod 62 is installed at the bottom of the transmission shaft 61; gear a63, gear a63 is installed at the bottom of the connecting rod 62; drive assembly 64, one e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com