Plate snapping machine and aerated concrete blank manufacturing device

A technology of trigger and body, which is applied in the field of aerated concrete body manufacturing equipment, and can solve the problems of high difficulty in overhaul and maintenance, and low breaking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

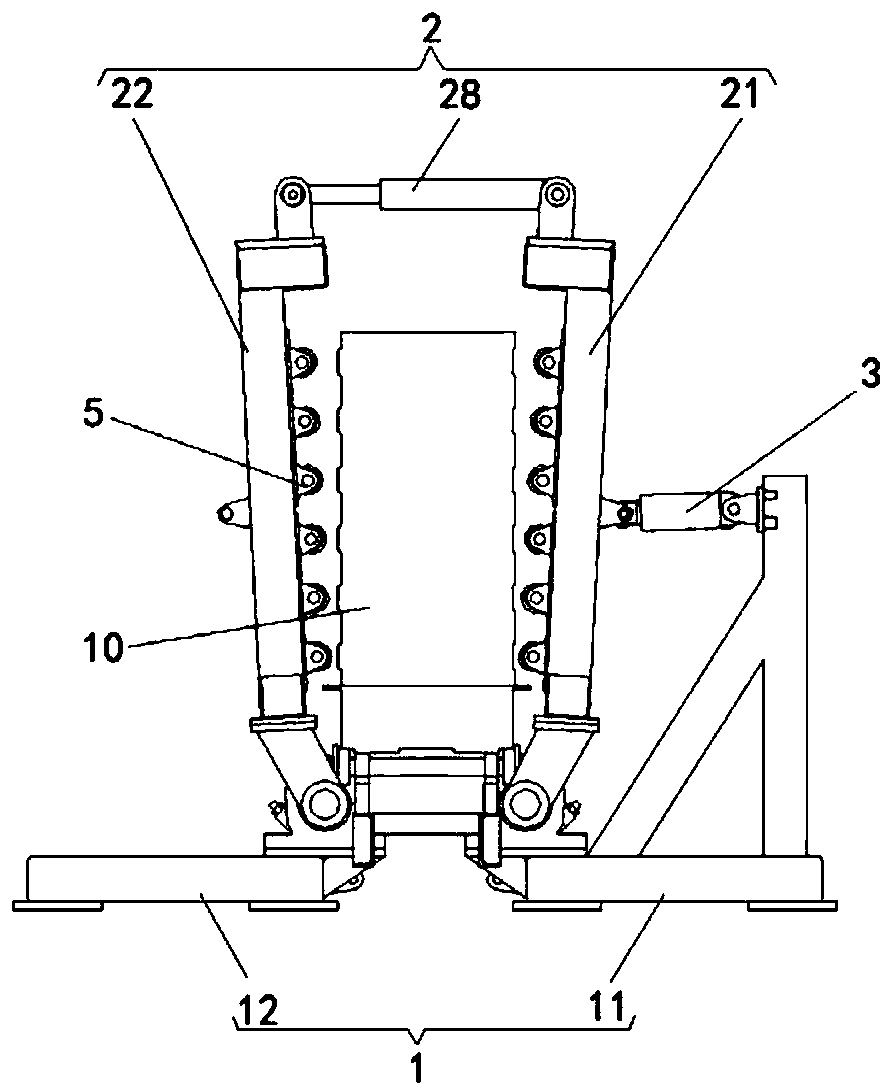

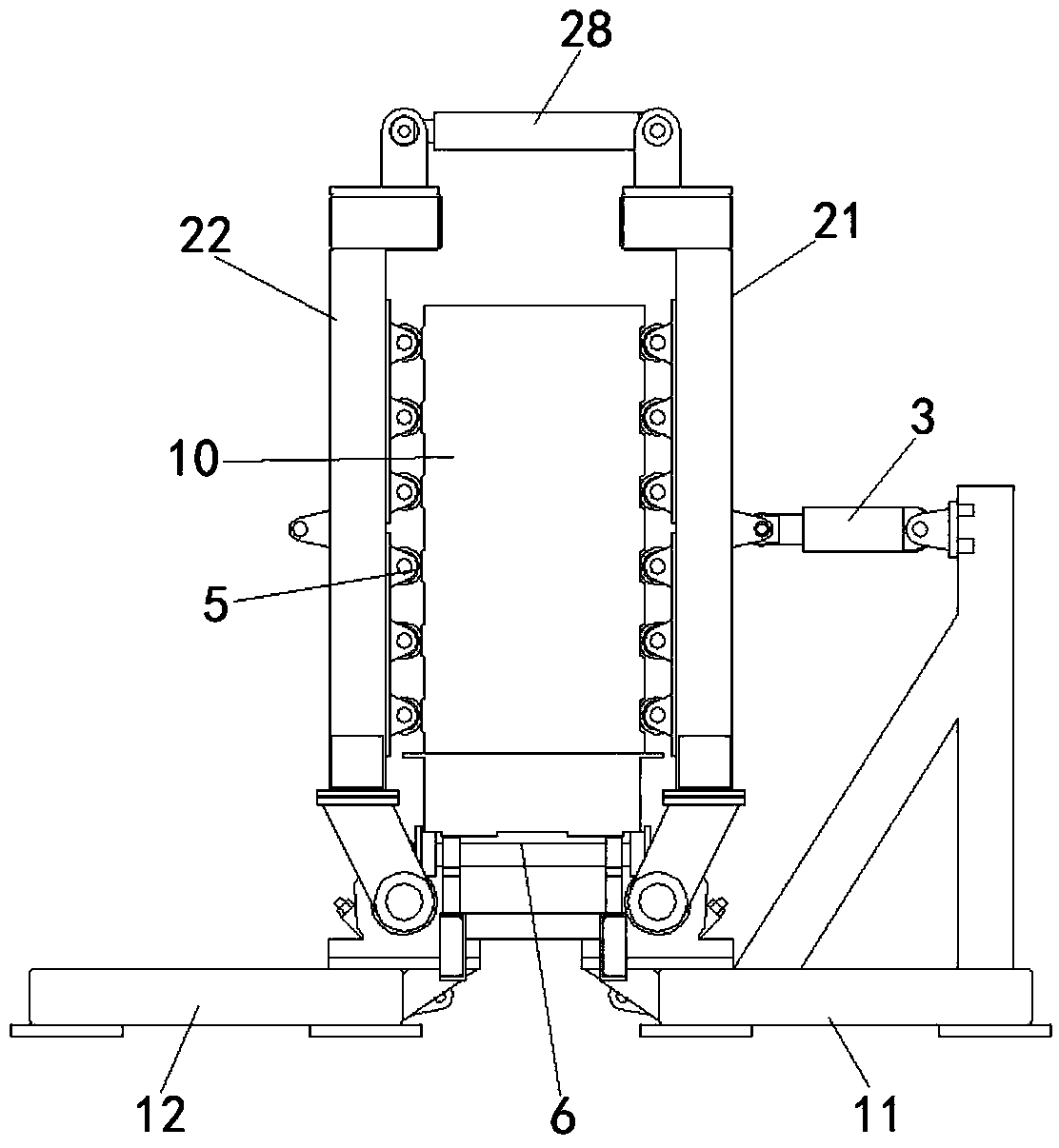

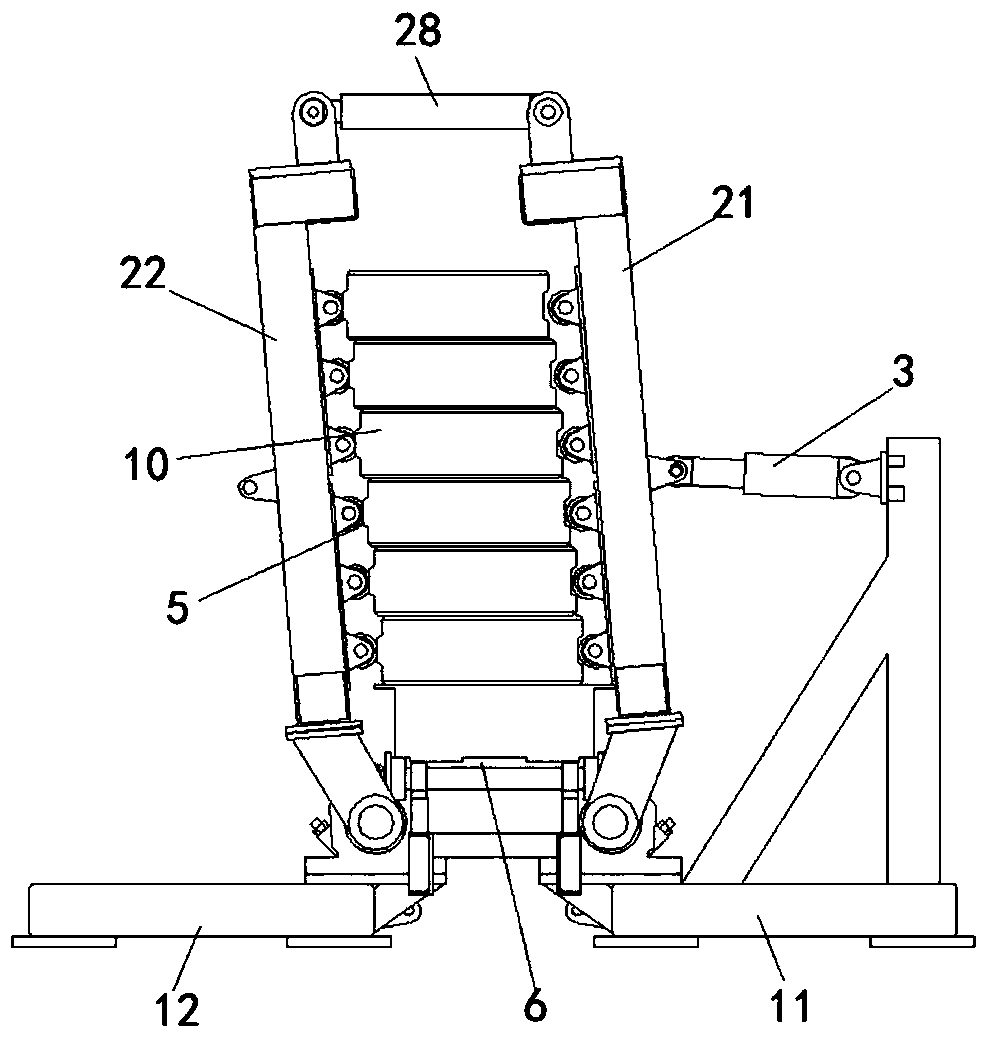

[0050] The board breaking machine provided in this embodiment, such as Figure 1 to Figure 11 As shown, it includes a breaking assembly 2, a driving assembly 3 and an installation structure 1; Components 22 are respectively movably connected with installation structure 1; drive assembly 3 is connected with split component 2, and is used to drive the first split component 21 and the second split component 22 to tilt in the same direction, so that the first split component 21 and the second split component The two breaking parts 22 cooperate to split a plurality of blanks 10 along the direction of the cutting surface of the blanks.

[0051] Wherein, the first breaking part 21 and the second breaking part 22 are rotationally connected with the installation structure 1 respectively, or the first breaking part 21 and the second breaking part 22 are respectively slidingly connected with the installation structure 1 . The installation structure 1 may be a base, or any suitable form ...

Embodiment 2

[0101] The device for manufacturing an aerated concrete body provided in this embodiment includes the board breaking machine provided in Embodiment 1. The first breaking part 21 and the second breaking part 22 are respectively arranged on both sides of a plurality of green bodies 10, and after the expansion and contraction drives the first breaking part 21 and the second breaking part 22 to tilt in the same direction, the first breaking part Part 21 presses one side of a plurality of green bodies 10, and the second splitting member 22 blocks the other side of a plurality of green bodies 10, so that adjacent green bodies 10 are staggered by a suitable distance in the horizontal direction, thereby breaking apart the stuck ones. Body 10. The aerated concrete body manufacturing device provided in this embodiment can separate a plurality of coherent green bodies 10 in one operation to improve the splitting efficiency, and a small amount of oil cylinders are required in the drive as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com