Preparation method and application of doubly-physically-crosslinked self-healing polymer elastomer

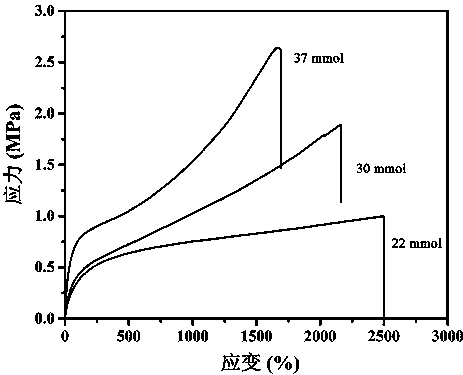

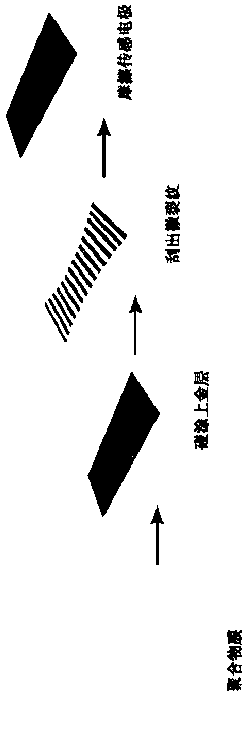

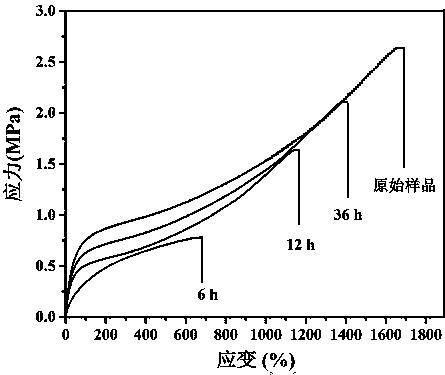

A physical cross-linking, polymer technology, applied in the field of polymer materials, can solve the problem of not being able to improve the mechanical strength, tensile properties and self-healing ability of polymers at the same time High-performance electronic skin, weak hydrogen bonds, unable to improve the mechanical strength of polymers improvement and other issues, to achieve excellent sensing and self-healing performance, simple preparation process, insensitivity to notch and good self-healing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1 A preparation method of dual physical cross-linked self-healing polymer elastomer includes the following steps:

[0029] ⑴ Dissolve 4 g of poly(dimethylsiloxane)-terminated bis(3-aminopropyl) and 2 mL of triphenylamine in 36 mL of chloroform, and stir in an ice bath under the protection of nitrogen for 1 h , Get a mixed solution.

[0030] (2) Add 2 mL of 0.1 g / mL chloroform solution with 2,4-toluene diisocyanate dissolved in 36 mL of mixed solution dropwise, after the addition is complete, stir and react for 1 h to obtain a viscous shape Gel.

[0031] ⑶ Dissolve aluminum trichloride in tetrahydrofuran to obtain solution I with a concentration of 0.5 g / mL;

[0032] ⑷ Completely dissolve 5 g of gel in 60 mL of tetrahydrofuran to obtain solution II;

[0033] ⑸ Pour 2 mL of solution I into 45 mL of solution II and stir at 60°C for 24 hours to obtain a viscous gel;

[0034] ⑹10 mL of colloid was spread on a glass plate treated with octadecyltrichlorosilane, dried at room te...

Embodiment 2

[0035] Example 2 A preparation method of dual physical cross-linked self-healing polymer elastomer includes the following steps:

[0036] ⑴ Dissolve 5 g of poly(dimethylsiloxane)-terminated bis(3-aminopropyl) and 3 mL of triphenylamine in 36 mL of chloroform, and stir in an ice bath under the protection of nitrogen for 3 h , Get a mixed solution.

[0037] ⑵ Add 3 mL of 0.1 g / mL chloroform solution with 2,6-toluene diisocyanate dissolved in 36 mL of mixed solution dropwise, after the addition is complete, stir and react for 2 hours to obtain a viscous shape Gel.

[0038] ⑶ Dissolve ferric nitrate in tetrahydrofuran to obtain solution I with a concentration of 0.6 g / mL;

[0039] ⑷ Completely dissolve 7 g of gel in 60 mL of tetrahydrofuran to obtain solution II;

[0040] ⑸ Pour 3 mL of solution I into 45 mL of solution II and stir at 80°C for 36 h to obtain a viscous colloid;

[0041] ⑹10 mL of colloid was spread on a glass plate treated with octadecyltrichlorosilane, dried at room temper...

Embodiment 3

[0042] Example 3 A preparation method of dual physical cross-linked self-healing polymer elastomer includes the following steps:

[0043] ⑴ Dissolve 6 g of poly(dimethylsiloxane)-terminated bis(3-aminopropyl) and 4 mL of triphenylamine in 36 mL of chloroform, and stir in an ice bath under nitrogen protection for 2 h , Get a mixed solution.

[0044] ⑵Add 4 mL of 0.1 g / mL chloroform solution with 4,4-methyl bis(phenyl isocyanate) dissolved in 36 mL of mixed solution dropwise. After the addition is complete, stir and react for 1.5 h , To get a viscous gel.

[0045] ⑶ Dissolve copper chloride in tetrahydrofuran to obtain a solution I with a concentration of 0.8 g / mL;

[0046] ⑷ Completely dissolve 8 g of gel in 60 mL of tetrahydrofuran to obtain solution II;

[0047] ⑸ Pour 4 mL of solution I into 45 mL of solution II and stir at 70°C for 30 hours to obtain a viscous colloid;

[0048] ⑹10 mL of colloid was spread on a glass plate treated with octadecyltrichlorosilane, dried at room tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap