Split type cylinder body

A split type, cylinder block technology, applied in the direction of cylinder, cylinder head, engine components, etc., can solve the problems of poor design inheritance and difficult maintenance, and achieve the effect of solving difficult maintenance, accurate design, and solving poor design inheritance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

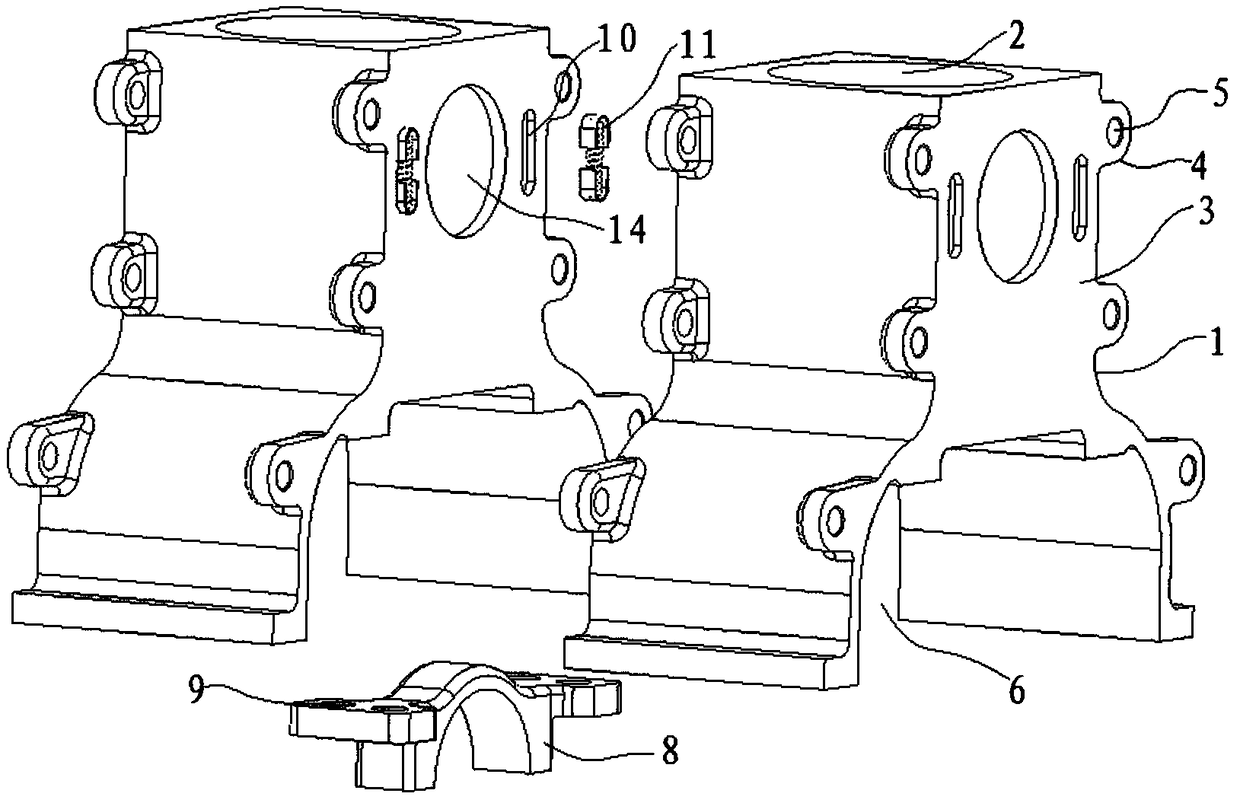

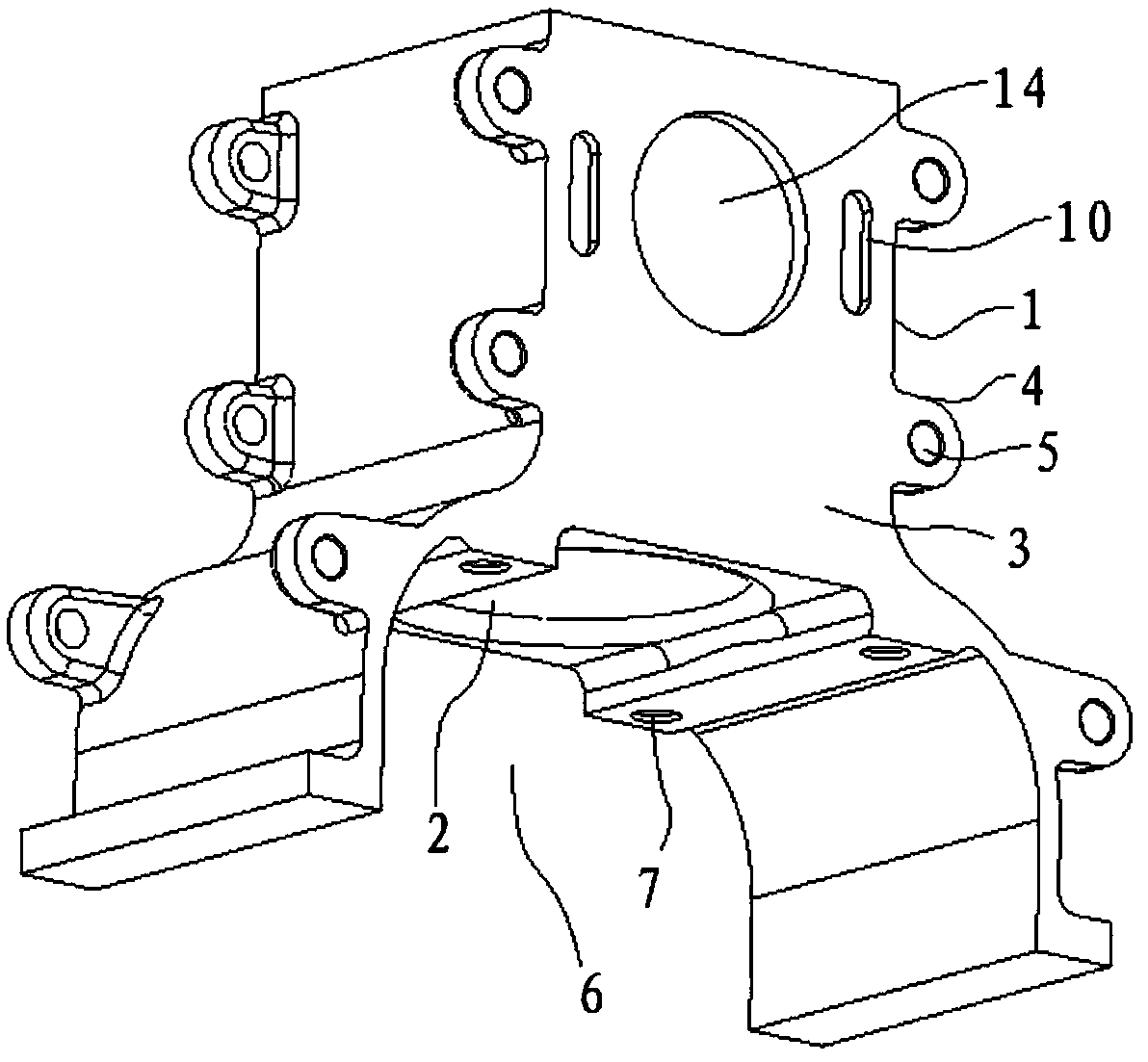

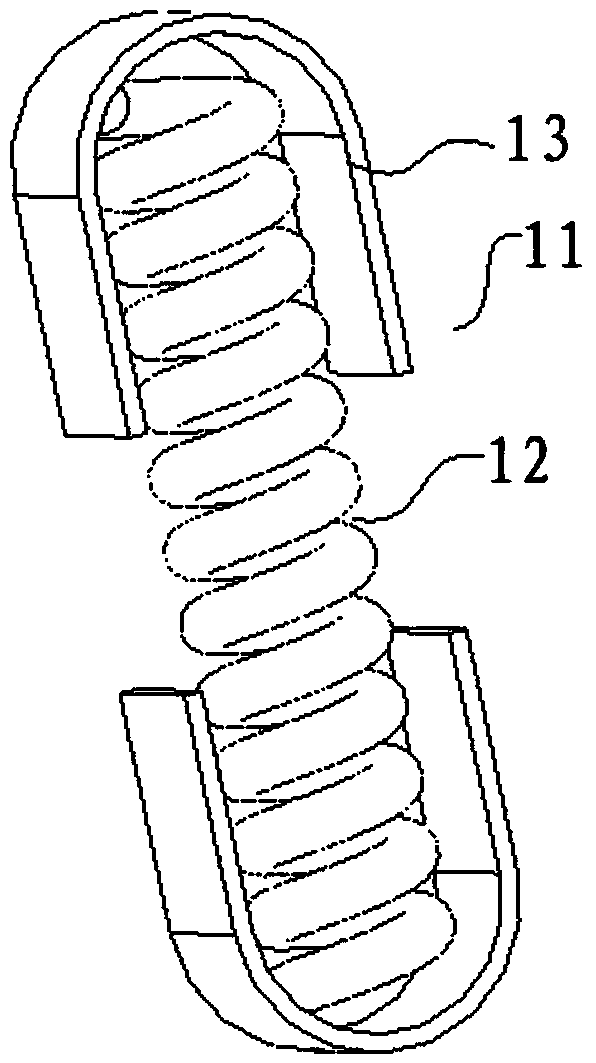

[0021] Such as Figure 1 to Figure 4 As shown, the embodiment of the present invention provides a split cylinder block, which is formed by bonding and fixing a plurality of cylinder bore bodies 1 arranged side by side in sequence, and the adjacent cylinder bore bodies 1 are combined by applying glue and rubber rings. Each cylinder bore body 1 is provided with a piston movement passage 2 and a cooling passage, each cylinder bore main body 1 is provided with a piston movement passage 2, and the two adjacent cylinder bore bodies 1 joints are formed with a fitting fixing surface 3, the opposite sides of the fitting fixing surface 3 are provided with a plurality of lugs 4 protruding outward, the number and position of the lugs 4 are determined according to actual needs, here Without limitation, e...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap