Hole plug of paddle lifting hole and installation method

An installation method and hoisting hole technology are applied in the directions of rotating propellers, engine seals, rotary propellers, etc., to achieve the effect of improving service life and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

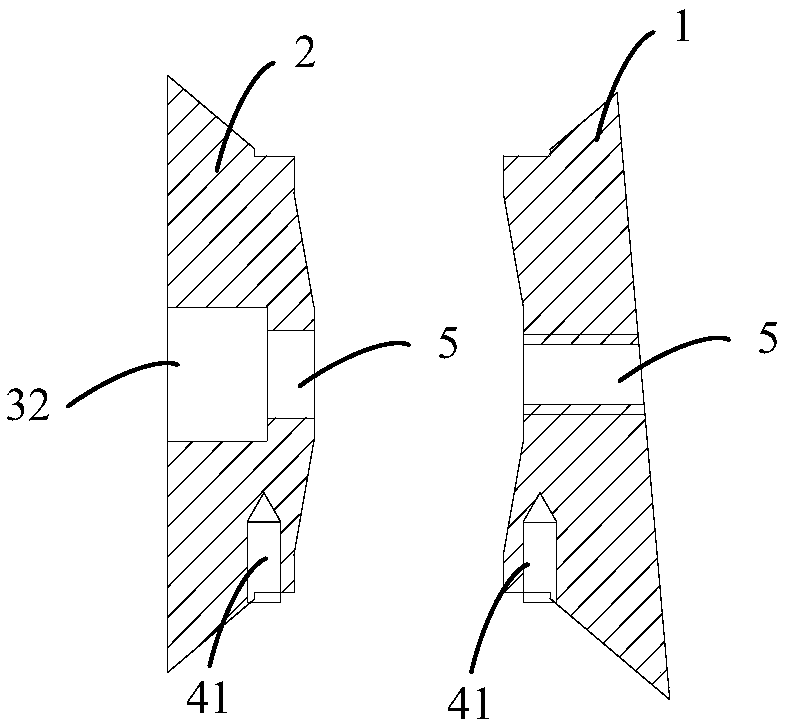

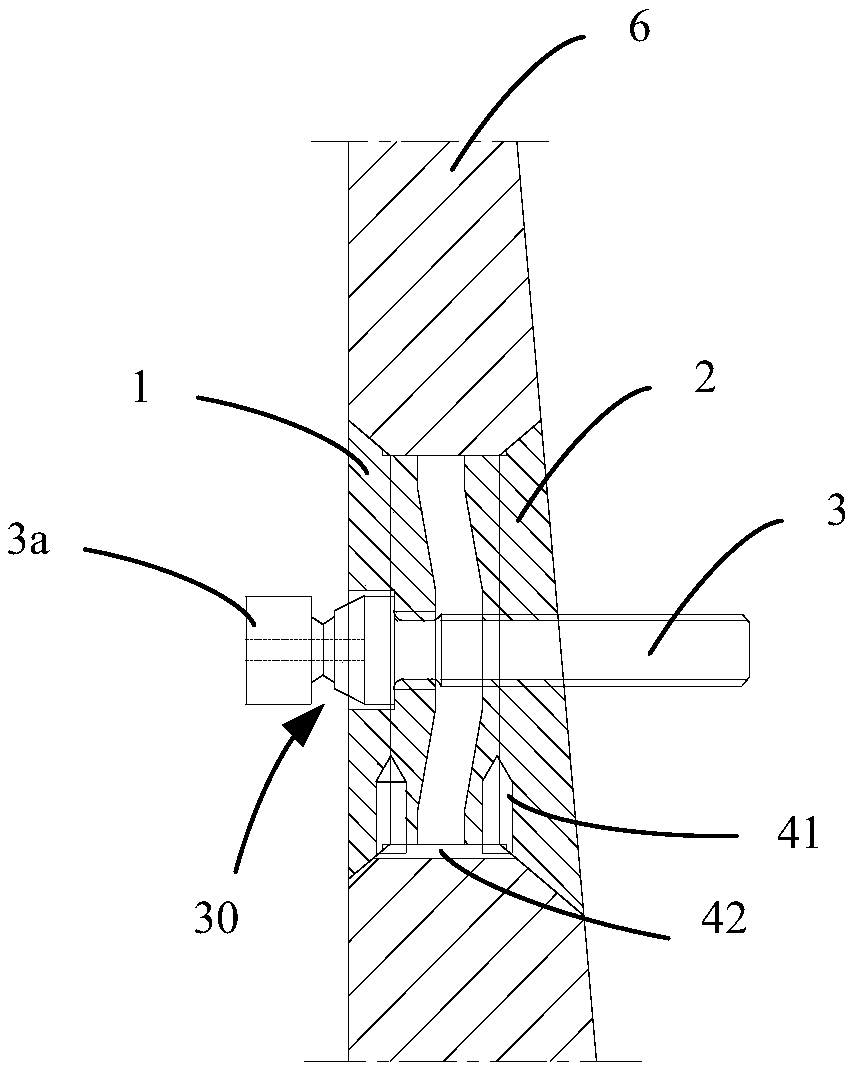

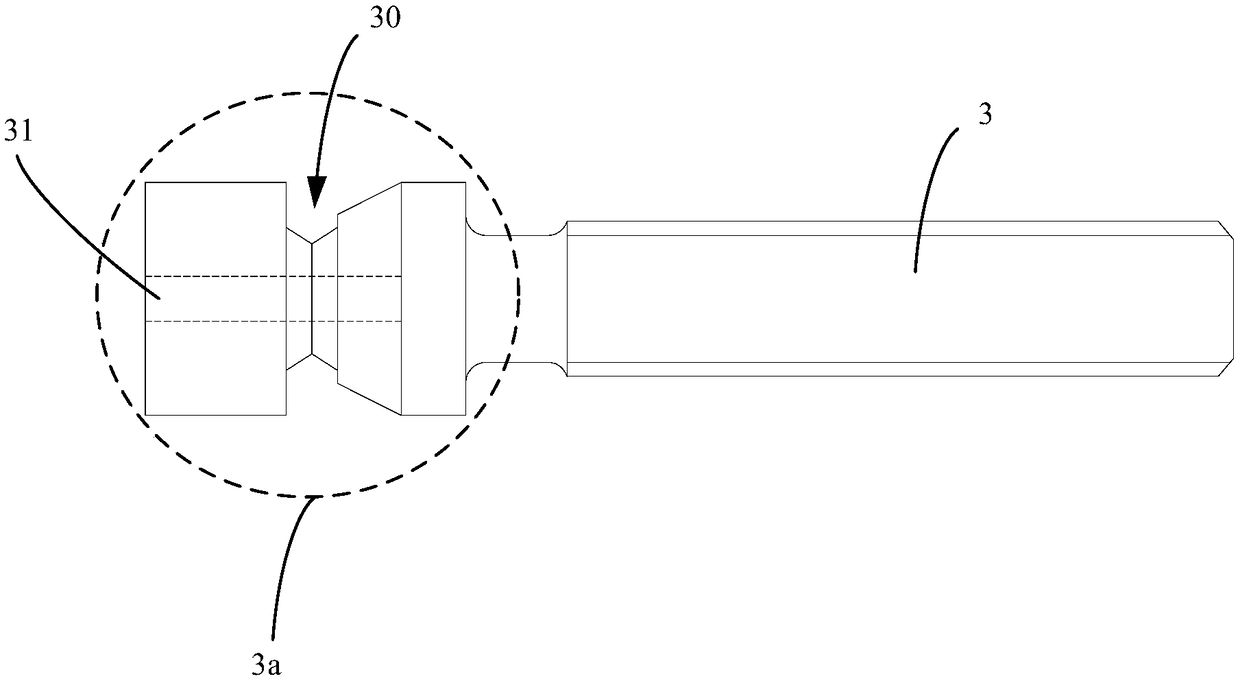

[0028] figure 1 It is a structural schematic diagram of a hole plug for a blade hoisting hole provided by an embodiment of the present invention. Such as figure 1 As shown, the hole plug includes: a first plug 1, a second plug 2 and a connecting piece, the first plug 1 is inserted at one end of the blade hoisting hole, the second plug 2 is inserted at the other end of the blade hoisting hole, The connecting piece is located in the blade lifting hole for connecting the first plug 1 and the second plug 2 .

[0029] In the embodiment of the present invention, when the hole plug is installed to block the blade hoisting hole, the blade hoisting hole is blocked respectively through the first plug and the second plug. Since the hole plug is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com