An RFID-based Automatic Test Management System for Distribution Line Fault Indicators

A fault indicator and management system technology, applied in the direction of instruments, data processing applications, collaborative work devices, etc., can solve the problems of high distance and location requirements, non-writeable information, poor reliability of labels, etc., to reduce the cost of manpower and material resources , improve the effect of low efficiency and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

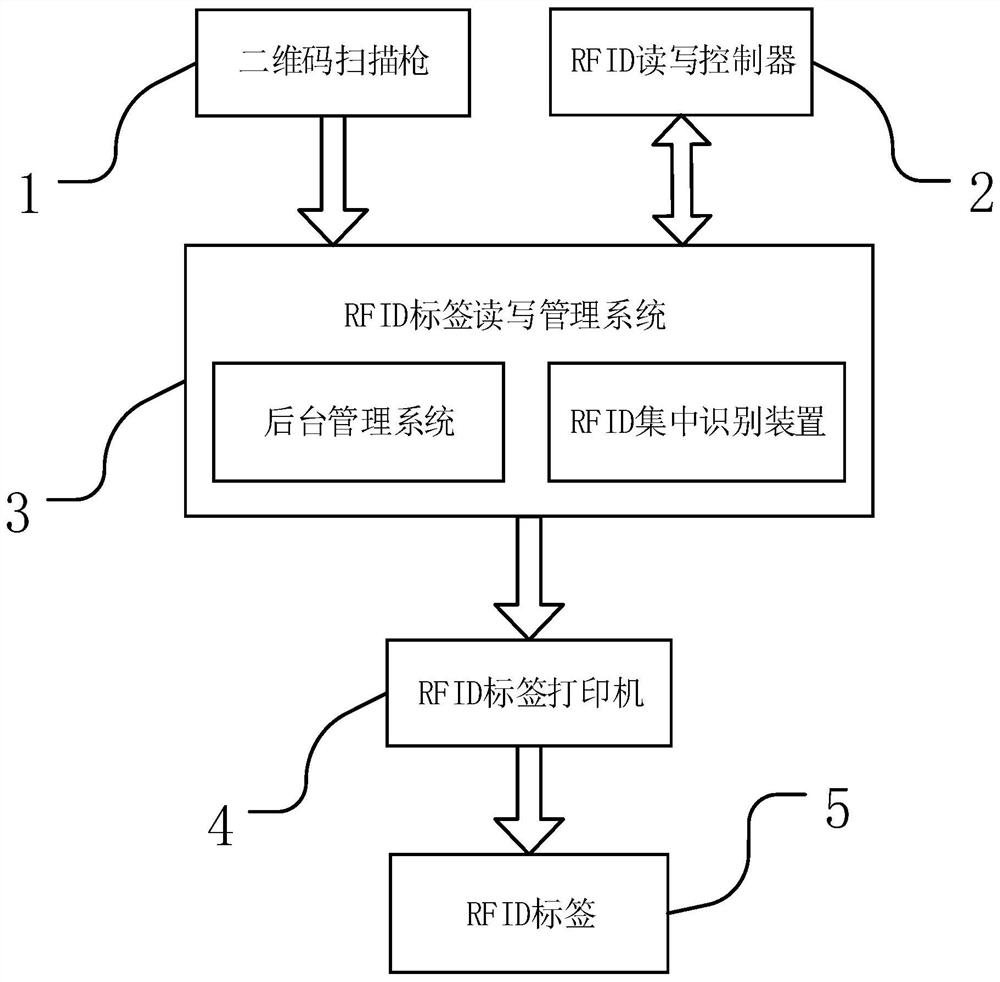

[0018] To achieve the above purpose, the present invention provides a RFID-based indicator management system, see figure 1 , including RFID tag reading and writing management system 3, two-dimensional code scanning gun 1, RFID reading and writing controller 2 and RFID label printer 4, two-dimensional code scanning gun 1 is used to read the two-dimensional code of the indicator and will read from the two-dimensional code Enter the ledger information read in the RFID label reading and writing management system 3, and the RFID label printer 4 is used to print the indicator information stored in the RFID label reading and writing management system 3 to the RFID label 5 for identifying and managing the indicator , the RFID read-write controller 2 is used...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com