Venturi mixing device with position-adjustable injector holes in throat part

A Venturi mixing and injection hole technology, applied in the Venturi field, can solve the problems of injection hole changes, high manpower and time costs, and achieve the effects of reducing the amount of consumables, changing the mixing effect of the device, and shortening the period of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

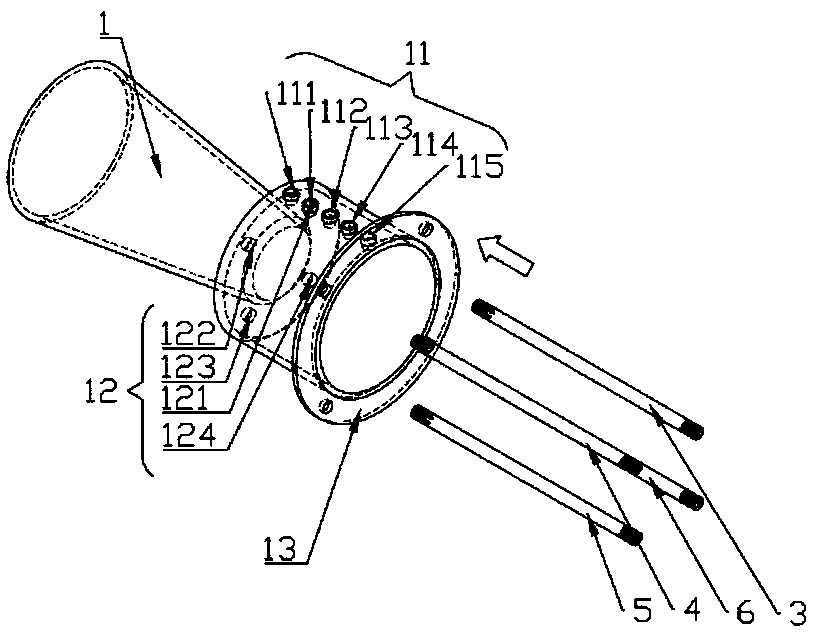

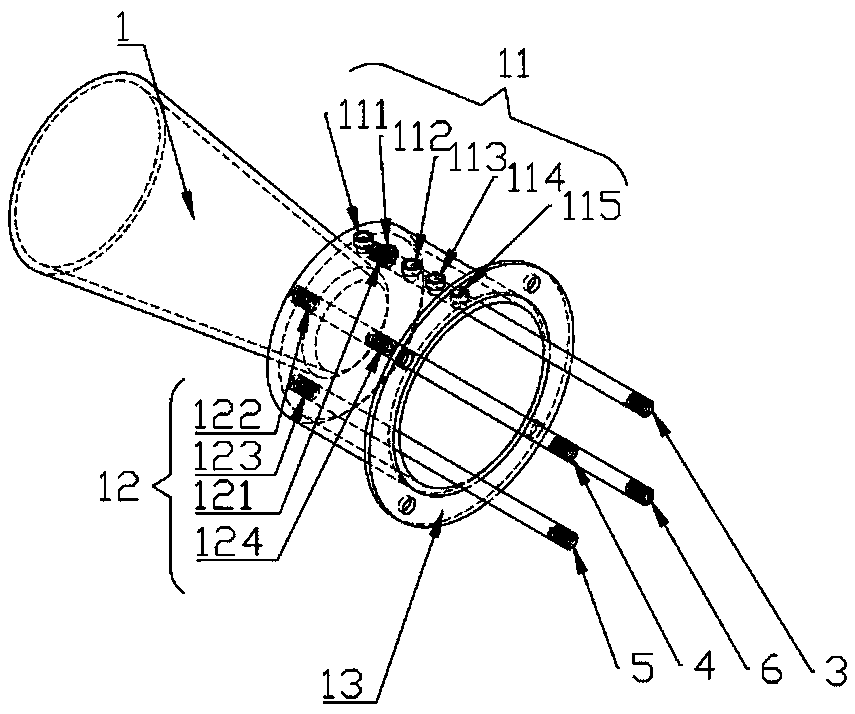

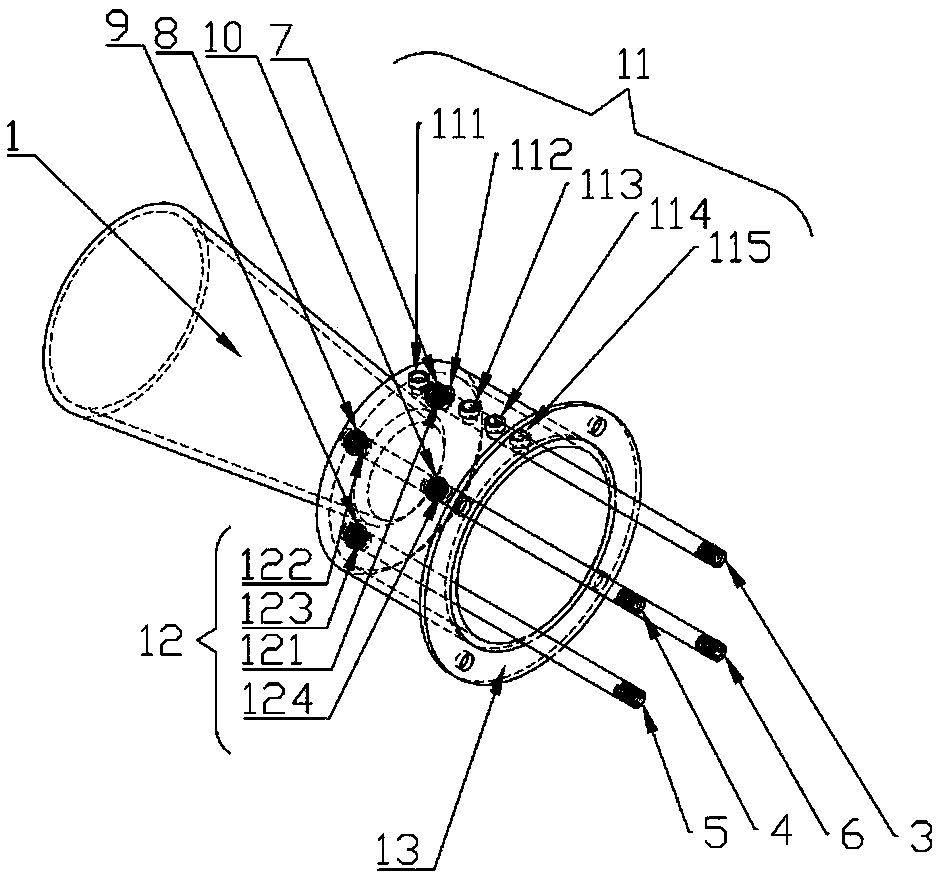

[0028]The present invention is a Venturi mixing device with adjustable throat ejection hole position, which comprises a venturi tube front section 1 with a cylindrical groove in the throat, a venturi tube rear section 2, stud bolts a3, and stud bolts b4 , Stud bolt c5 and stud bolt d6, nut a7, nut b8, nut c9, nut d10, nut e14, nut f15, nut g16, nut h17, single-head bolt a18, single-head bolt b19, single-head bolt c20, Single-headed bolt d24, nut i25, nut j26, nut k27, nut l28, injection hole spacer 29, adjustment spacer group 30. The front section 1 of the Venturi tube includes the front injection hole group 11, the front bolt through hole gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com