Automatic rubber frame cleaning line

An automatic cleaning and plastic frame technology, applied in cleaning methods and utensils, cleaning methods using liquids, dryers, etc., can solve the problems of low cleaning efficiency, high manual labor intensity, and unfavorable trends in production and processing automation, and achieve automation. High degree, improve cleaning efficiency, reduce the effect of manual operation intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

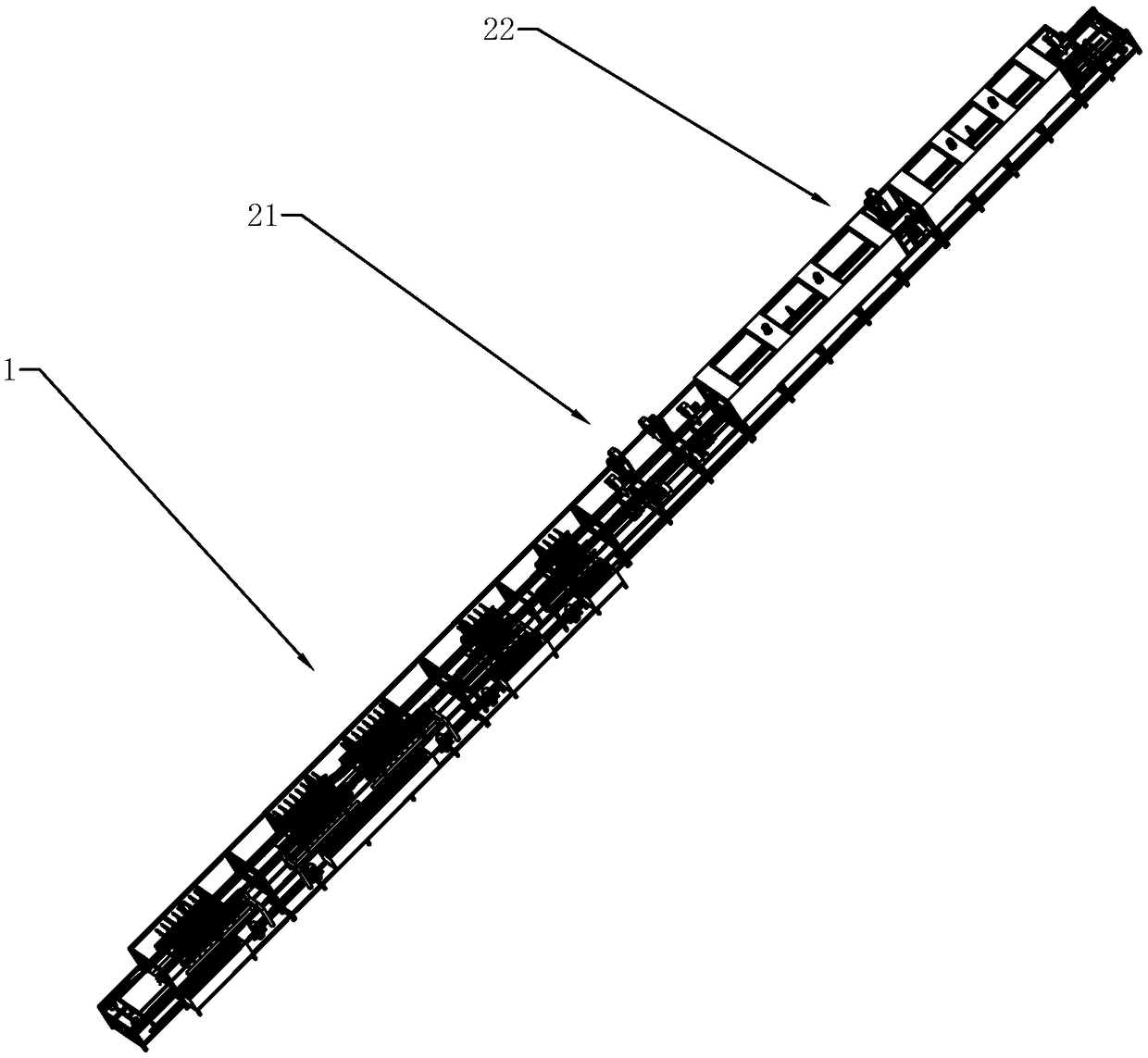

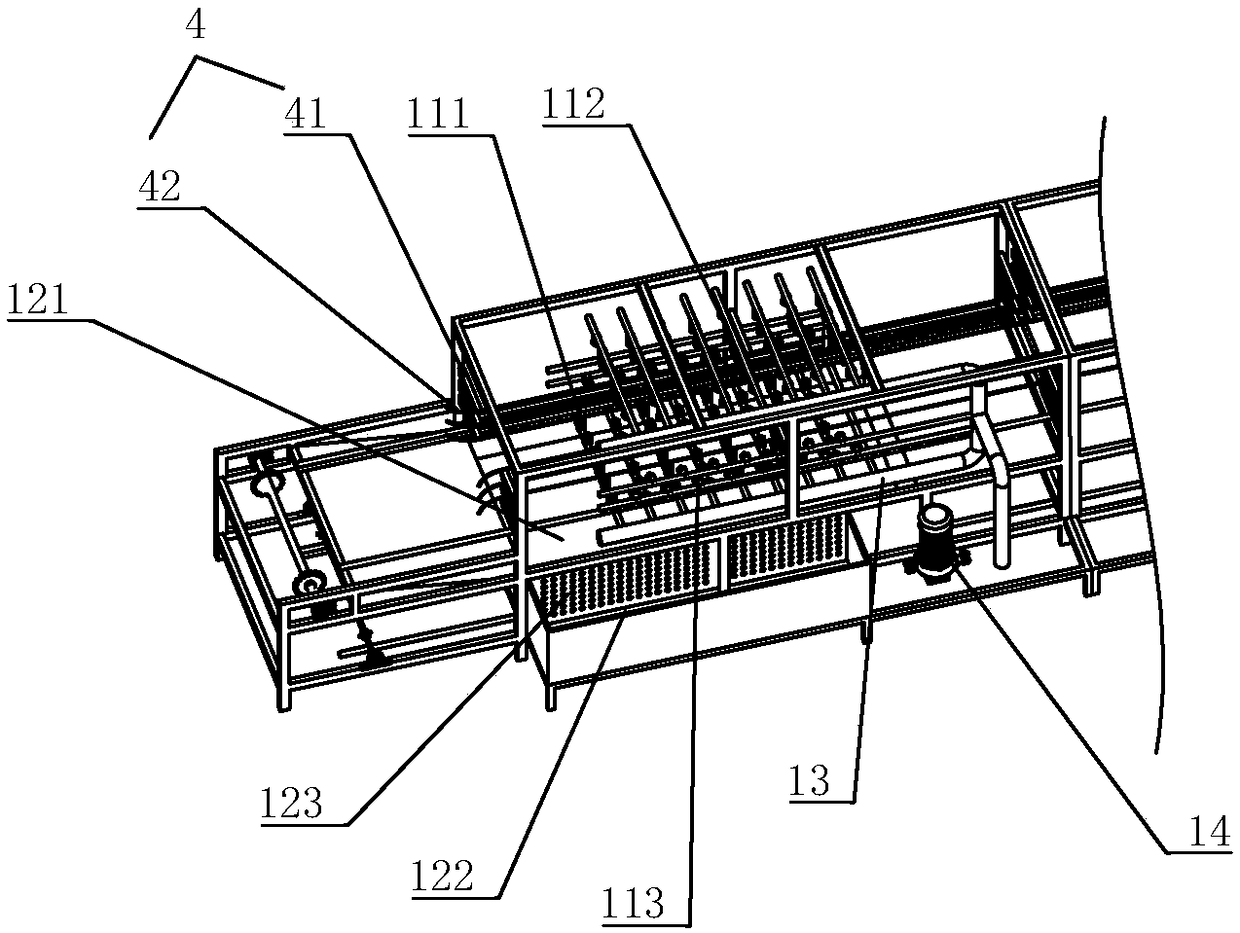

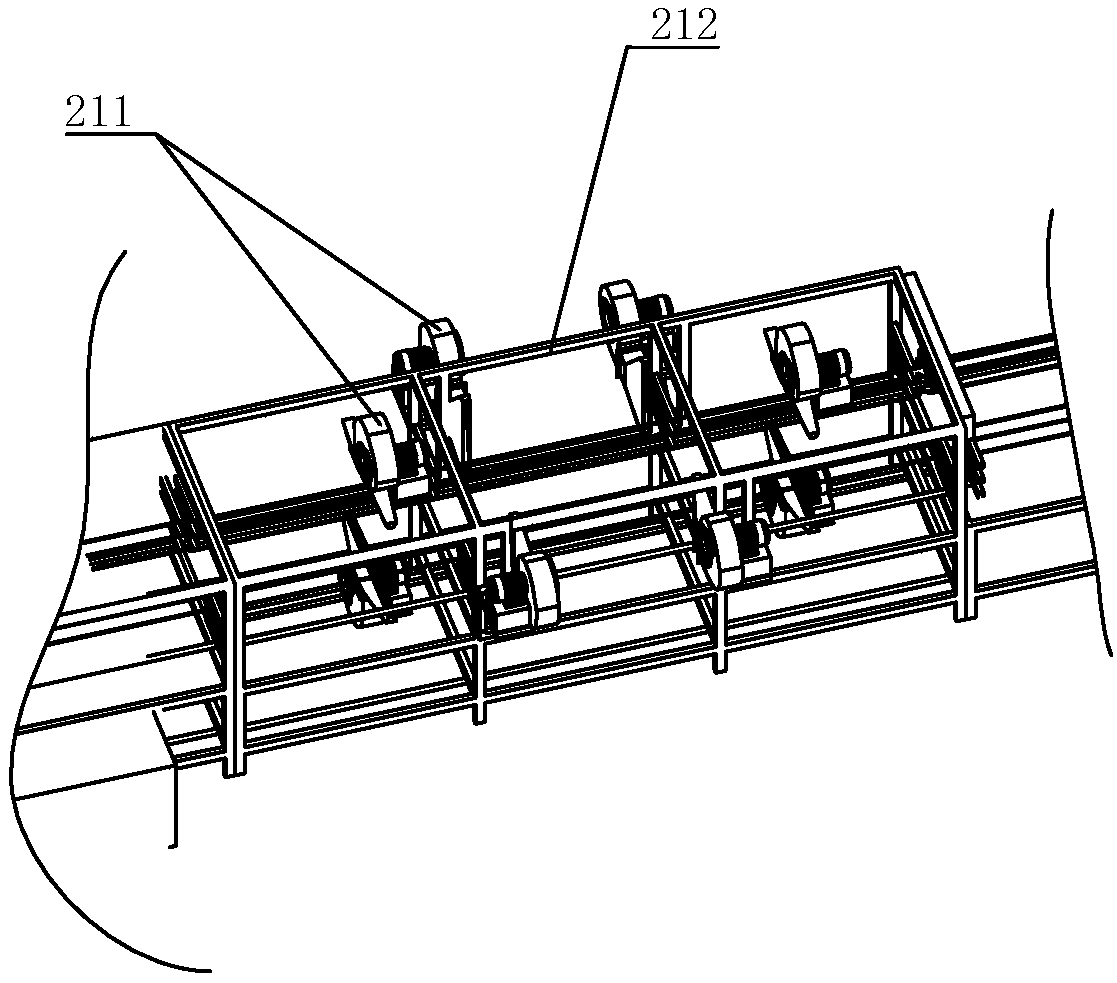

[0016] refer to Figure 1 to Figure 4 , a kind of plastic frame automatic cleaning line of the present invention, comprises cleaning device 1 and the air-drying device that is connected in described cleaning device 1, and the conveying roller that runs through described cleaning device 1 and air-drying device; Described cleaning device 1 includes spraying Port 11 and the water tank 12 arranged below the conveying roller, the spray port 11 is arranged above the water tank 12, including the lower spray port 111 and the upper spray port 112 respectively arranged below and above the conveying roller, the spray The mouth 11 is connected with the water inlet pump 14 through the connecting pipe 13, and the water inlet of the water inlet pump 14 is communicated with the water tank 12; the conveying roller is connected to the motor and is driven by the motor to rotate and convey; the air-drying device includes a first air-dry section 21 and a second Air-drying section 22; the first air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com