Efficient vibration-damping layered porous composite board

A composite board, layered technology, applied in the field of materials, can solve the problems of poor strength, insufficient vibration reduction effect, low sound insulation level, etc., and achieve the effect of low density, excellent mechanical properties, and conducive to vibration reduction and noise reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

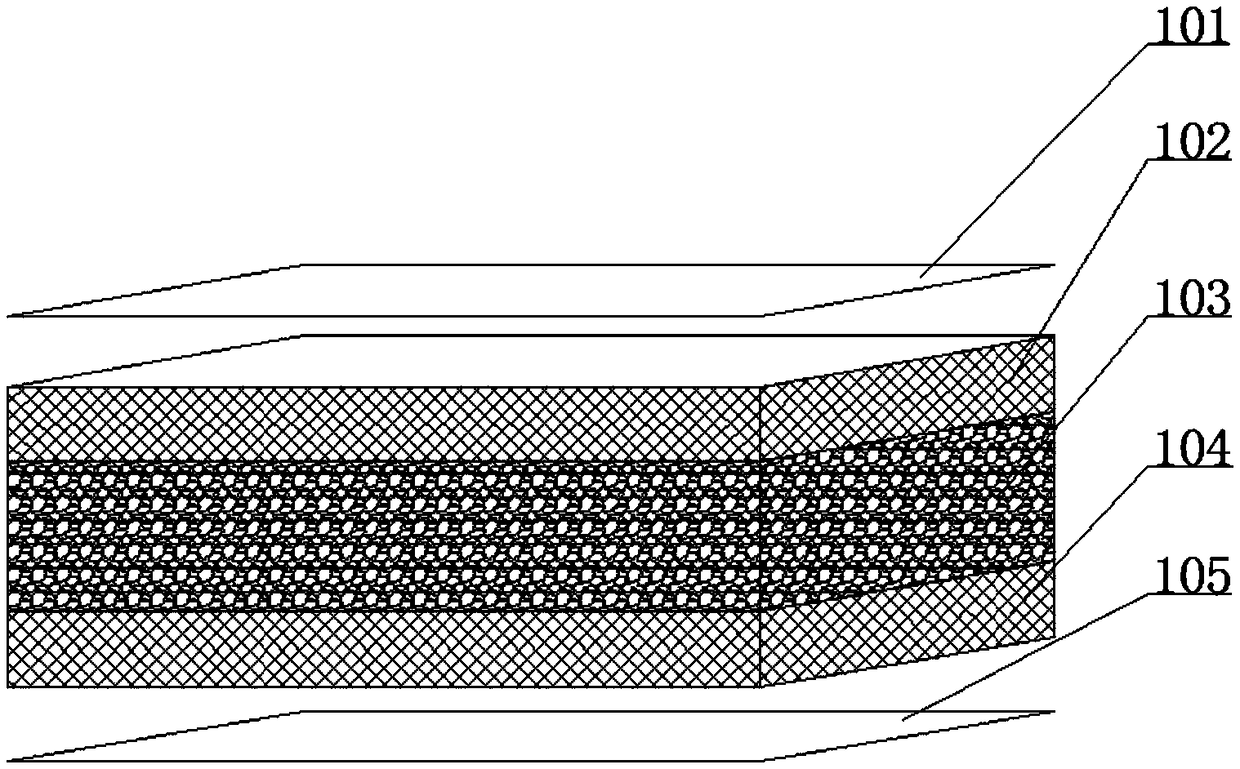

[0028] Such as figure 1 As shown, the overall structure of the panel is a sandwich structure composed of an upper panel 101 , middle-level porous interlayers 102 , 103 , 104 , and a lower panel 105 to improve the overall mechanical properties.

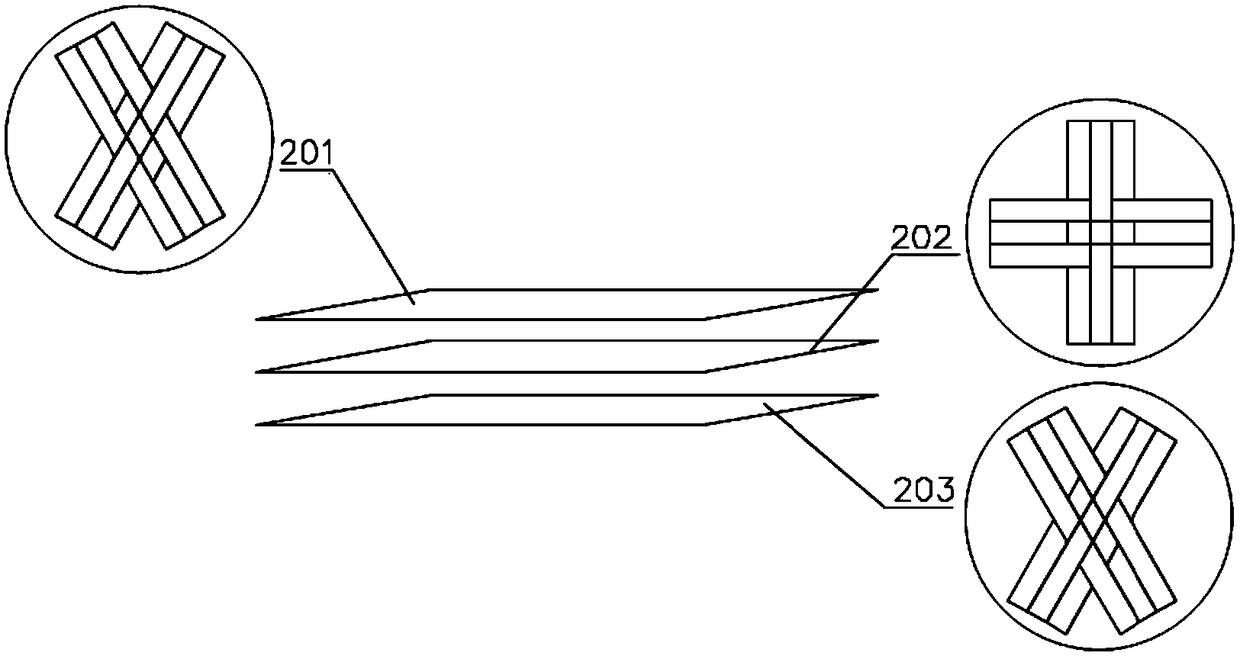

[0029] Such as figure 2 As shown, the upper panel 101 and the lower panel 105 are composite fiber layers, respectively including the upper aramid fiber layer 201, the middle aluminum fiber layer 202, and the lower aramid fiber layer 203. The sandwich structure composed of the three has good vibration damping Noise reduction effect. The tensile performance of aramid fiber is relatively outstanding, and the corresponding aluminum fiber layer has good compression resistance. The combination of the two through epoxy resin adhesive to form a sandwich board can complement each other and complement each other. At the sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com