Automatic battery exchange station for electric automobile

A technology for electric vehicles and battery swap stations, applied in electric vehicles, charging stations, electric power devices, etc., can solve the problems of poor user experience, long battery swap time, and small number of battery pack storage, saving space and cost , Increase the amount of storage, and improve the effect of user experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the following will be combined with the accompanying drawings and preferred embodiments to describe the specific implementation of an electric vehicle automatic power station and its effects according to the present invention. , as detailed below.

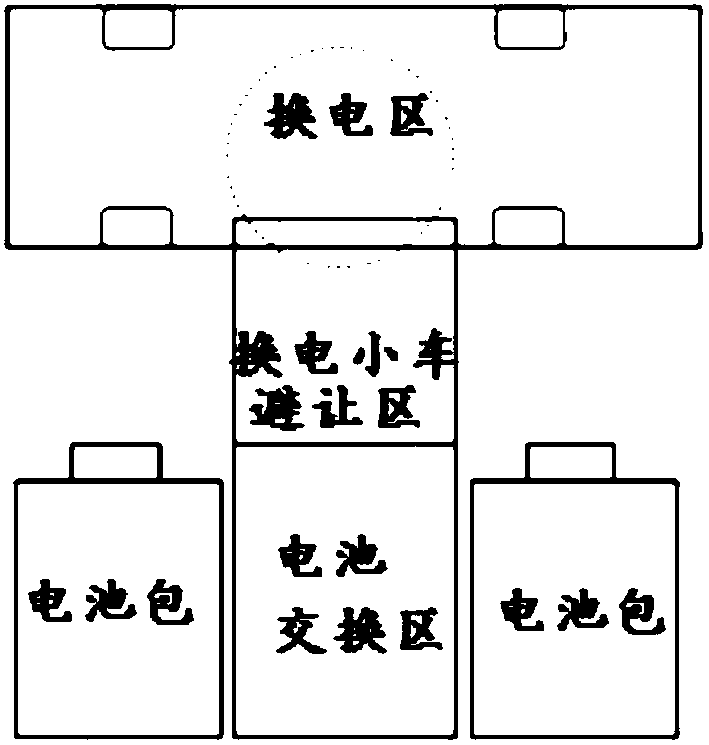

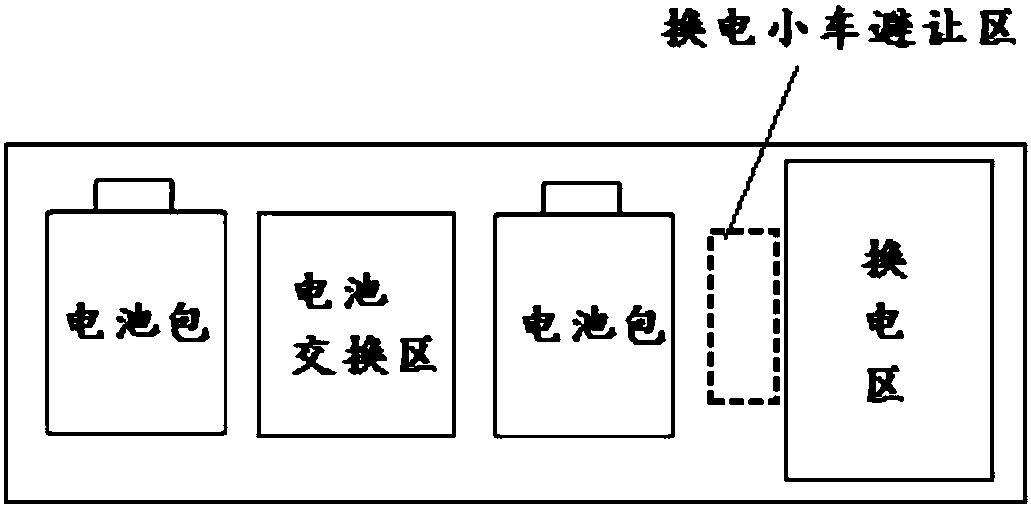

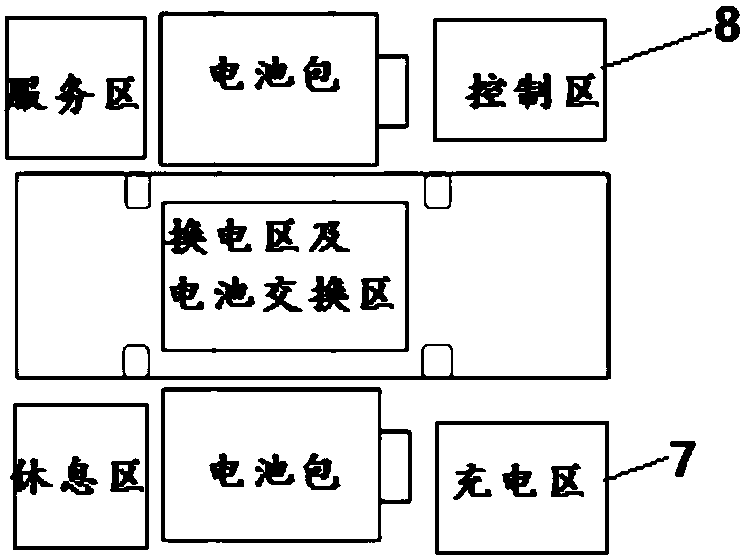

[0043] Such as Figure 3-8 As shown, the embodiment of the present invention provides an automatic battery swapping station for electric vehicles, including: a battery swapping platform 1, a guide rail 2, a battery pack storage device 3 and a battery swapping trolley 4. Among them, the battery exchange platform 1 is used to support and position the vehicle, and lift the vehicle to a preset battery exchange height. The guide rail 2 runs through the battery exchange platform 1 and protrudes from the battery exchange platform 1 at both ends, and the guide rail 2 serves as a running track of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com