Adjustable liquid injecting and seam cutting device

An adjustable and slot-cutting technology, which is applied in the direction of production fluid, wellbore/well components, earthwork drilling and production, etc., can solve problems such as roof fall, increased after-sales cost, and limited forming aperture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

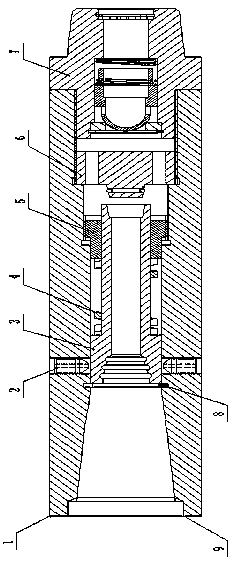

[0015] With reference to the figures covered in the accompanying drawings and specific practical instructions are as follows:

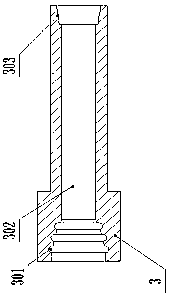

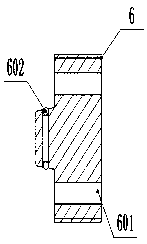

[0016] As shown in the figure, one end of the casing 1 is connected to the drill pipe through the drill pipe connector 9, and the other end is connected to the blowout prevention safety valve group 7 through the casing connector 707. The energy gathering valve core is installed in the casing 1 3. The energy-gathering spool 3 is provided with an energy-gathering damping groove 301, a drilling fluid channel 302, and a taper hole 303. The compression spring 4 is installed on the energy-gathering spool 3 and one end is connected to the pressure regulating mechanism 5. The energy-gathering spool 3 The opening and closing movement is carried out by the drilling fluid pressure forming movement, so that when the opening is realized, the high-pressure drilling fluid is sprayed from the nozzle 2, and the taper hole 303 in the energy-gathering valve core 3 is sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com