Heating platform for assisting screen removal

A heating platform and heating device technology, applied in the direction of ohmic resistance heating, ohmic resistance heating parts, electric heating devices, etc., can solve the problems of poor electrical components, high temperature of the fuselage, inconvenience, etc., to prevent uneven heating and reduce collisions With scratches, enhance the effect of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

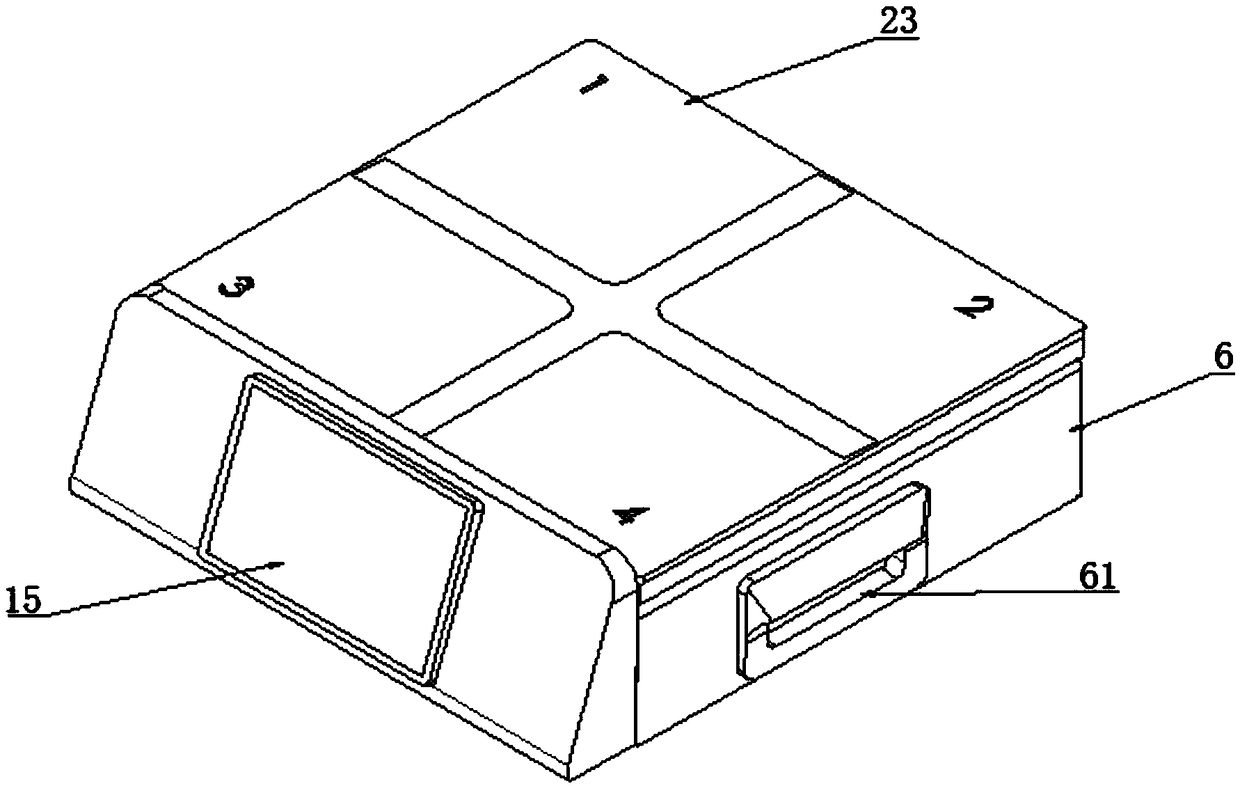

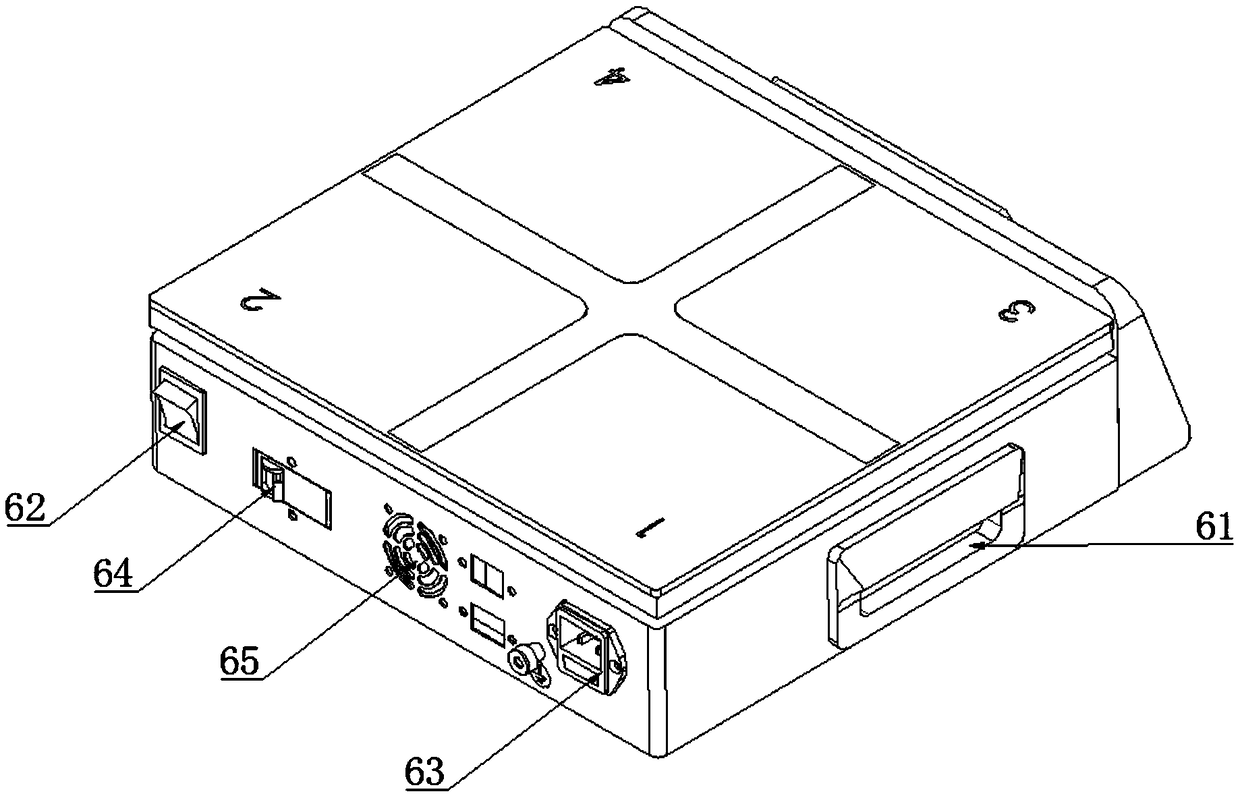

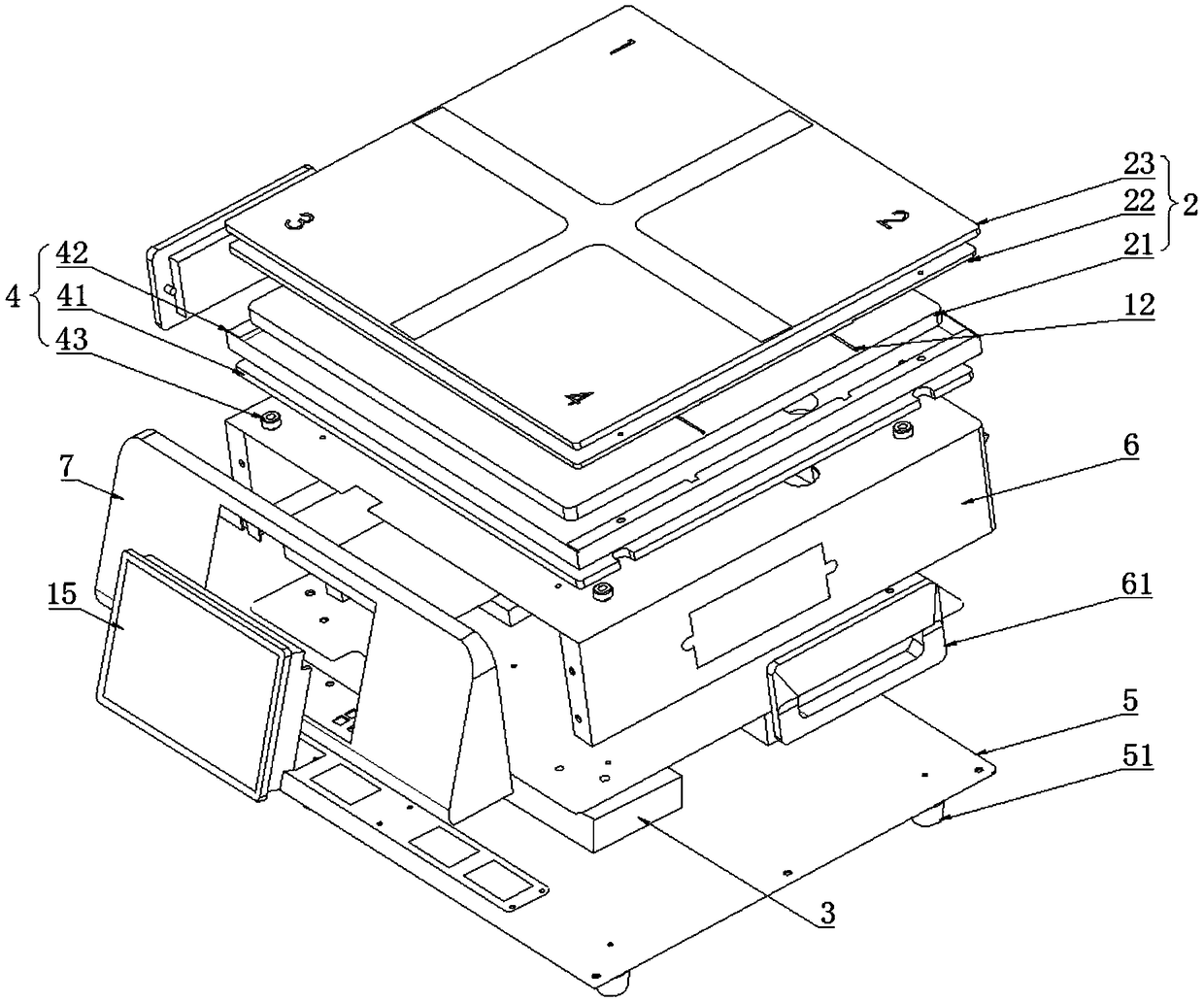

[0048] refer to Figures 1 to 6 As shown, the present invention provides a heating platform for auxiliary screen removal, including a control device 1, a heating device 2, and a power supply 3; the heating device 2 includes a heating plate 21, a heat conduction plate 22, and a silica gel plate 23; the heating plate 21. The heating conduction plate 22 and the silica gel plate 23 are stacked sequentially from bottom to top, and the silica gel plate 23 is used to place products; the power supply 3 is used to supply power to the entire heating platform; the control device 1 includes a main controller 11, several Temperature sensor 12, temperature controller 13, over-temperature protection device 16, several timing modules 14; The temperature controller 13 is placed on the heating plate 21 for controlling the heating temperature of the heating pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com