High-temperature deep well goaf filling slurry conveying system and method with cooling function

A technology for filling slurry and conveying system, which is applied in chemical instruments and methods, batching storage, batching batching instrument, etc., can solve the problems of complex system, high operating cost and high energy consumption, and achieves a high degree of intelligence and is easy to use and operate. , the effect of simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

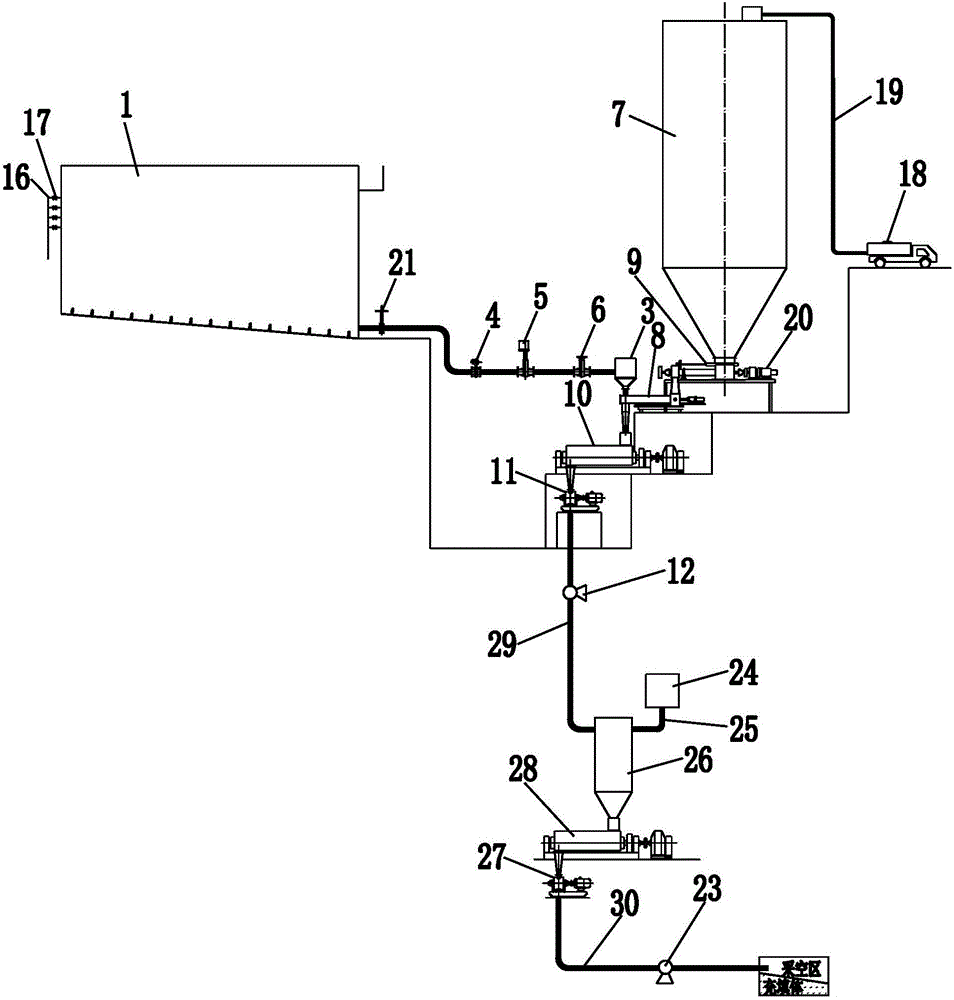

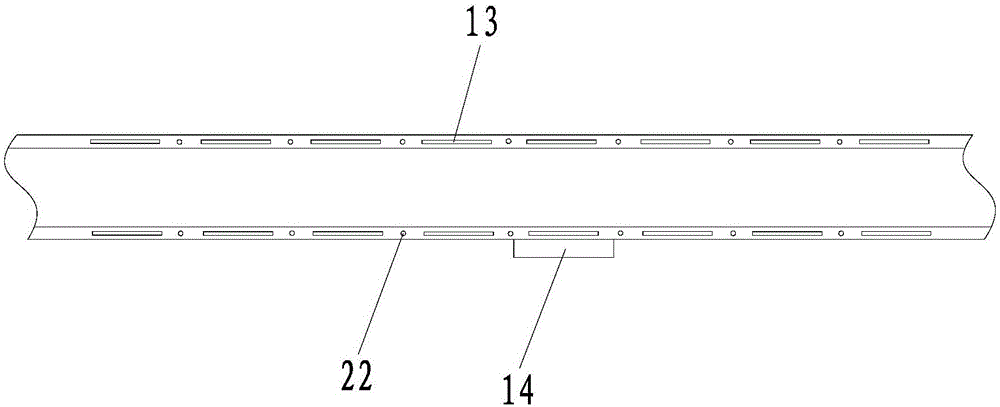

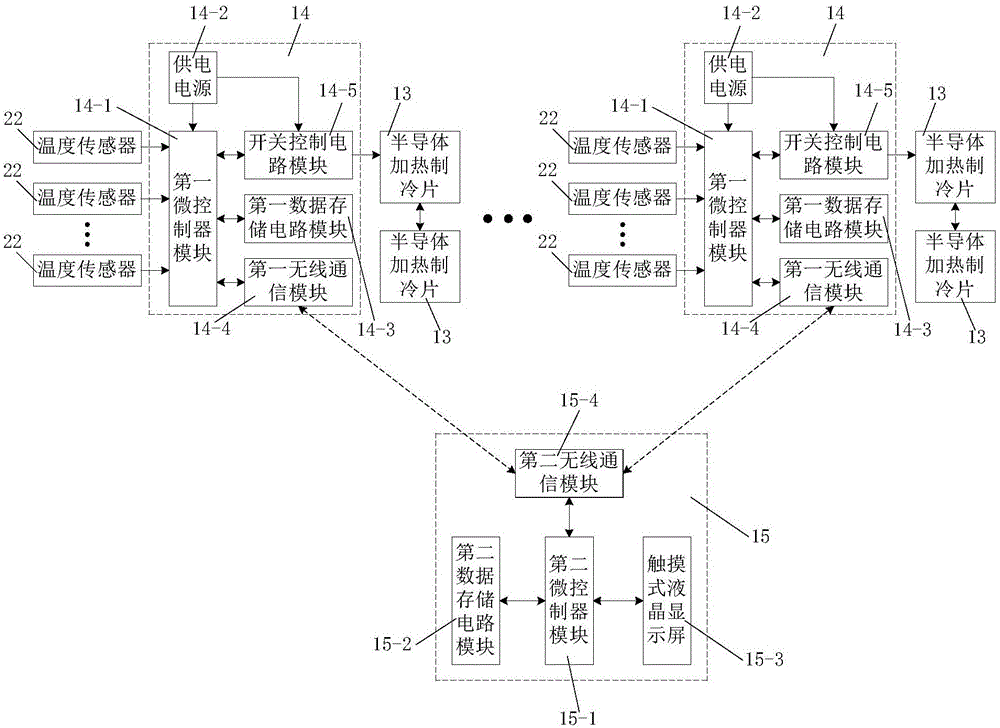

[0050] Such as figure 1 As shown, the high-temperature deep well goaf filling slurry conveying system with cooling function of the present invention includes an above-hole material conveying mechanism and an underground material conveying mechanism, and the above-hole material conveying mechanism includes a first material conveying mechanism and a second material conveying mechanism , the mixing mechanism on the well and the temperature master controller 15, the first material conveying mechanism includes a first material bin 1 for holding the first material, a hopper for transporting the first material mixed with ice cubes to the mixing mechanism 3 and the first material conveying pipeline 2 connected to the material outlet of the first material bin 1, the first material conveying pipeline 2 is connected with a material conveying switch valve 21, an electromagnetic flowmeter 4, an electric pinch valve 5 and a manual A pinch valve 6, the hopper 3 is connected to the end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com