Aluminum die casting machining device and method and aluminum die casting

An aluminum die-casting and processing equipment technology, applied in the field of aluminum die-casting products, can solve the problems of increasing equipment and operation complexity, low processing efficiency of through-hole chamfering, inability to handle, etc., to achieve processing efficiency, simplify equipment and space. compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings. Those skilled in the art will appreciate that these descriptions are only descriptive and exemplary, and should not be construed as limiting the protection scope of the present invention.

[0038] Aluminum die castings include automotive components such as wiper skeletons and automotive gearbox housings.

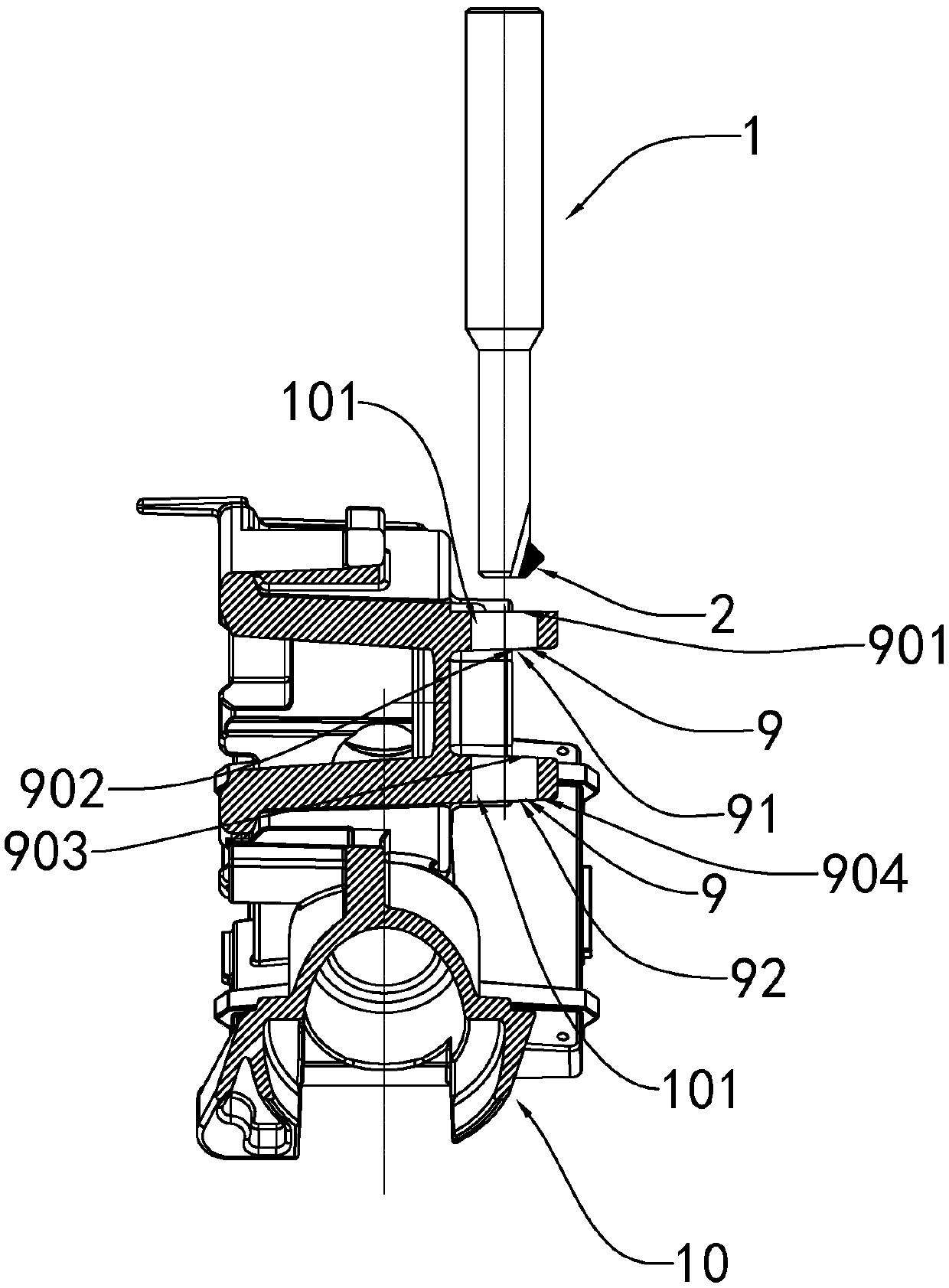

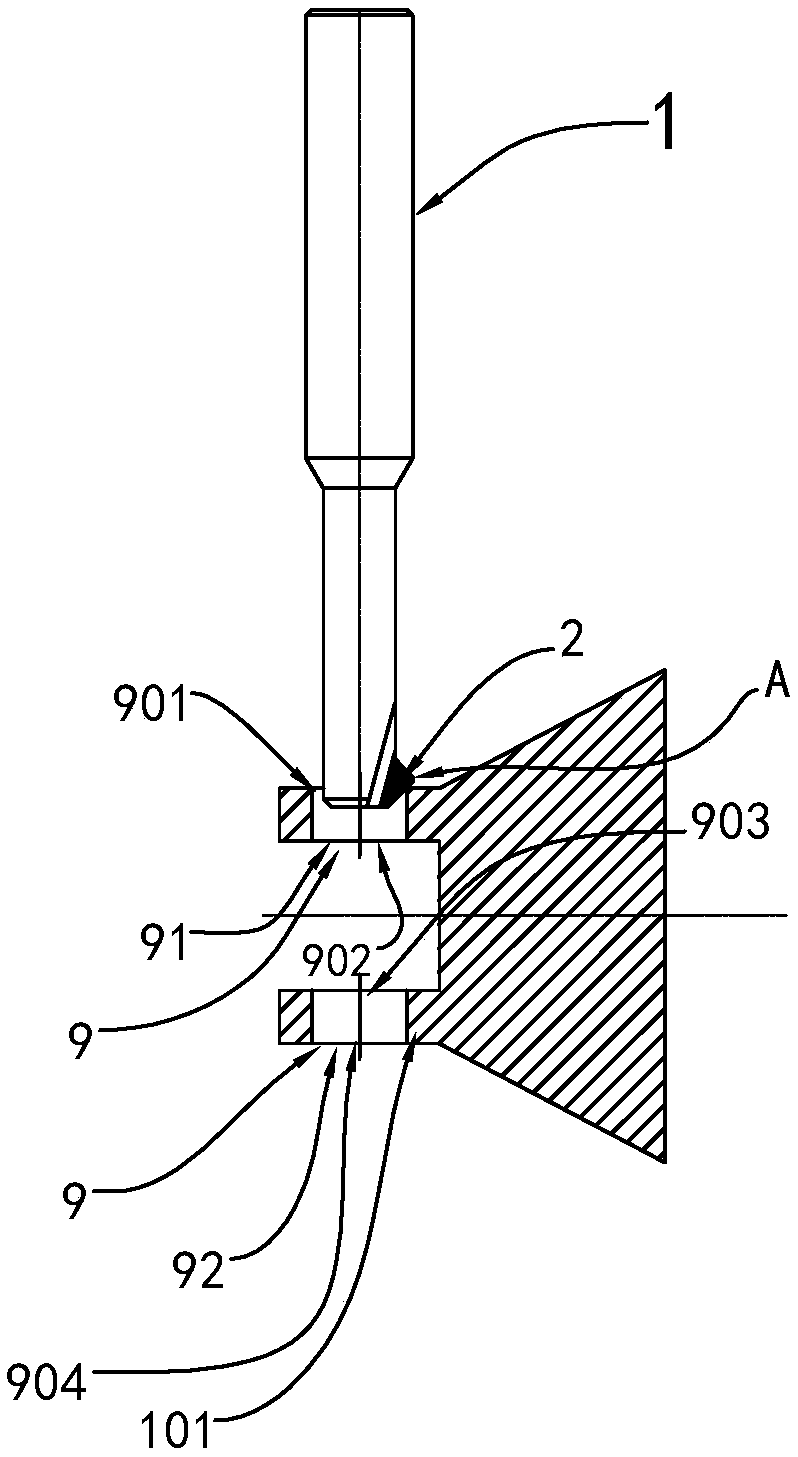

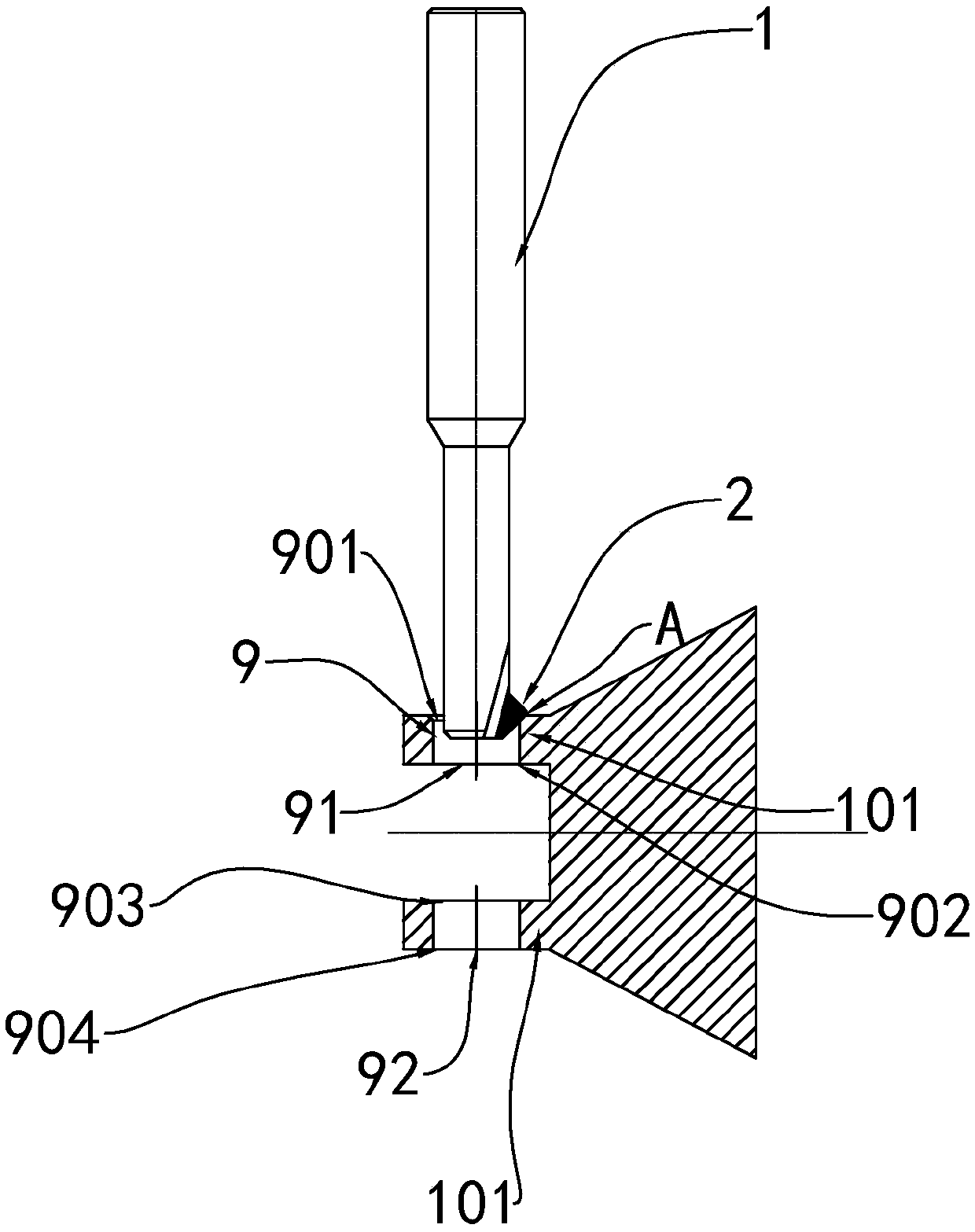

[0039] Such as Figure 1 to Figure 9 As shown, the aluminum die casting processing equipment is used for chamfering the two sides of the through hole 9 of the aluminum die casting 10. For processing the front edge 21 of the front chamfer of the through hole 9 of the aluminum die casting 10 and the reverse blade 22 of the reverse chamfer of the through hole 9 of the aluminum die casting 10, the distance from the center line of the rotating shaft 1 to the farthest end A of the blade portion 2 The distance is greater than the radius of the throu...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap