Three-dimensional material warehouse lifting device

A lifting device and material warehouse technology, applied in storage devices, transportation and packaging, etc., can solve the problems affecting the stability of the three-dimensional material warehouse, the impact of the three-dimensional material warehouse, and the occupation of factory space, so as to ensure safety, reduce labor intensity, and facilitate The effect of the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

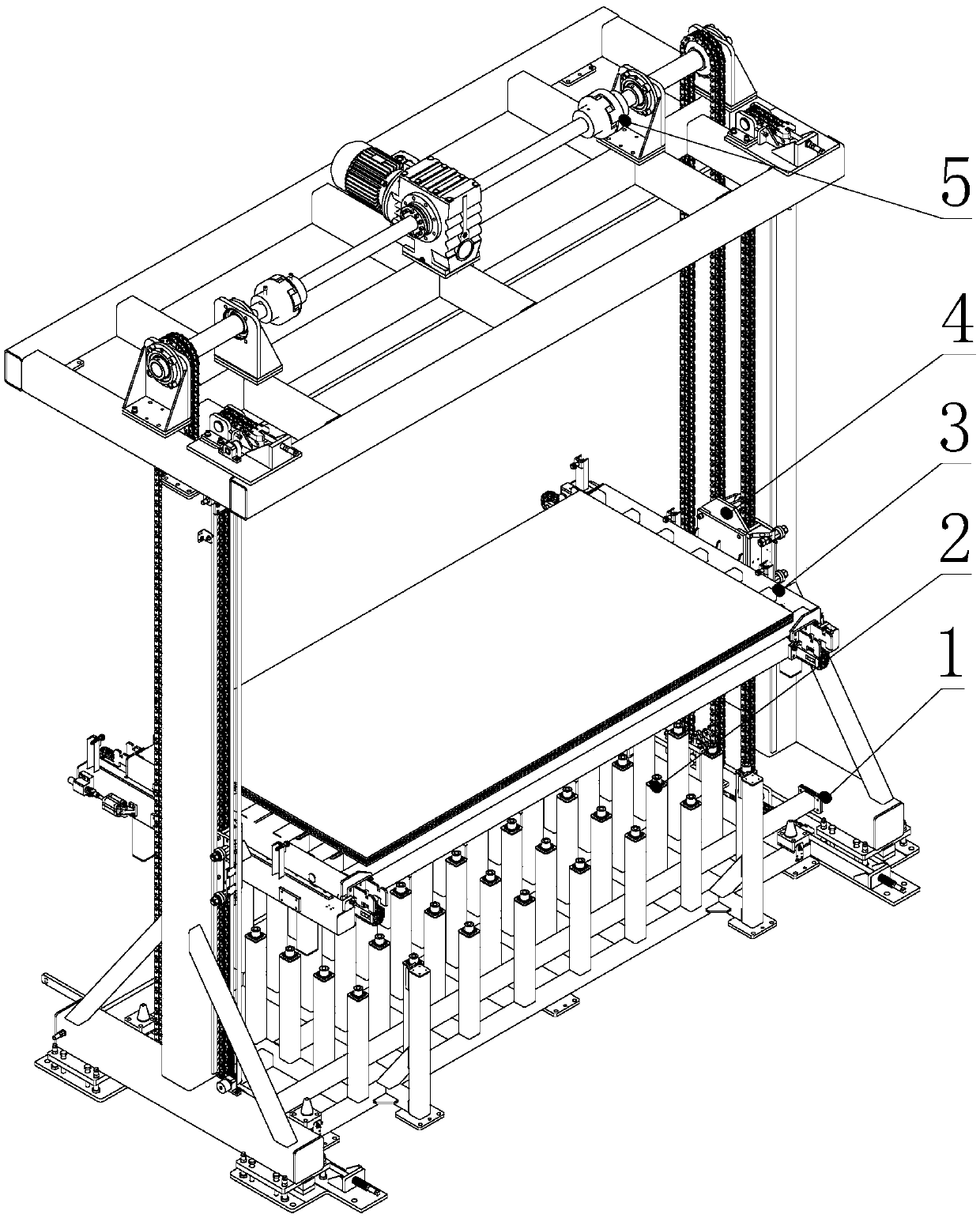

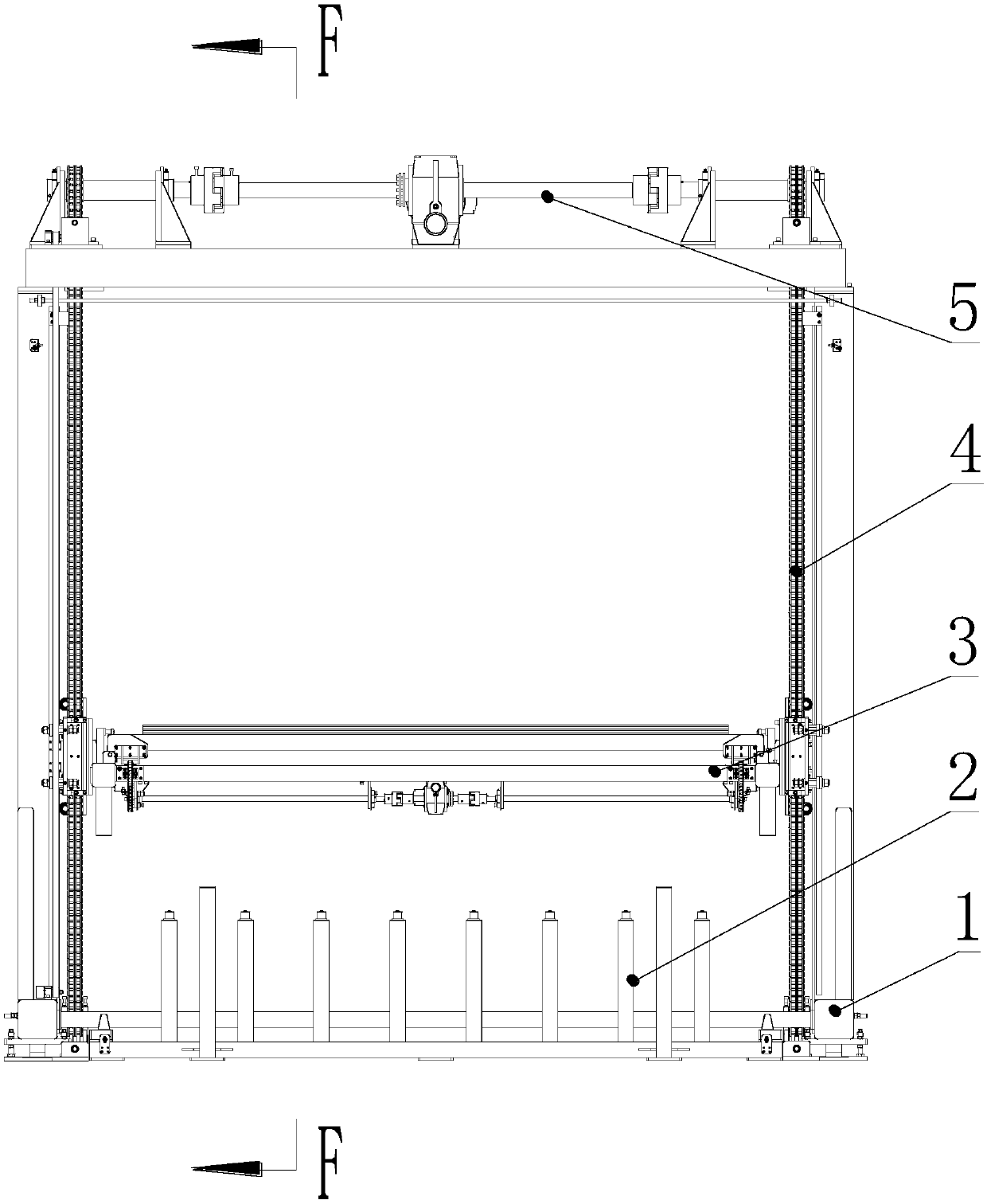

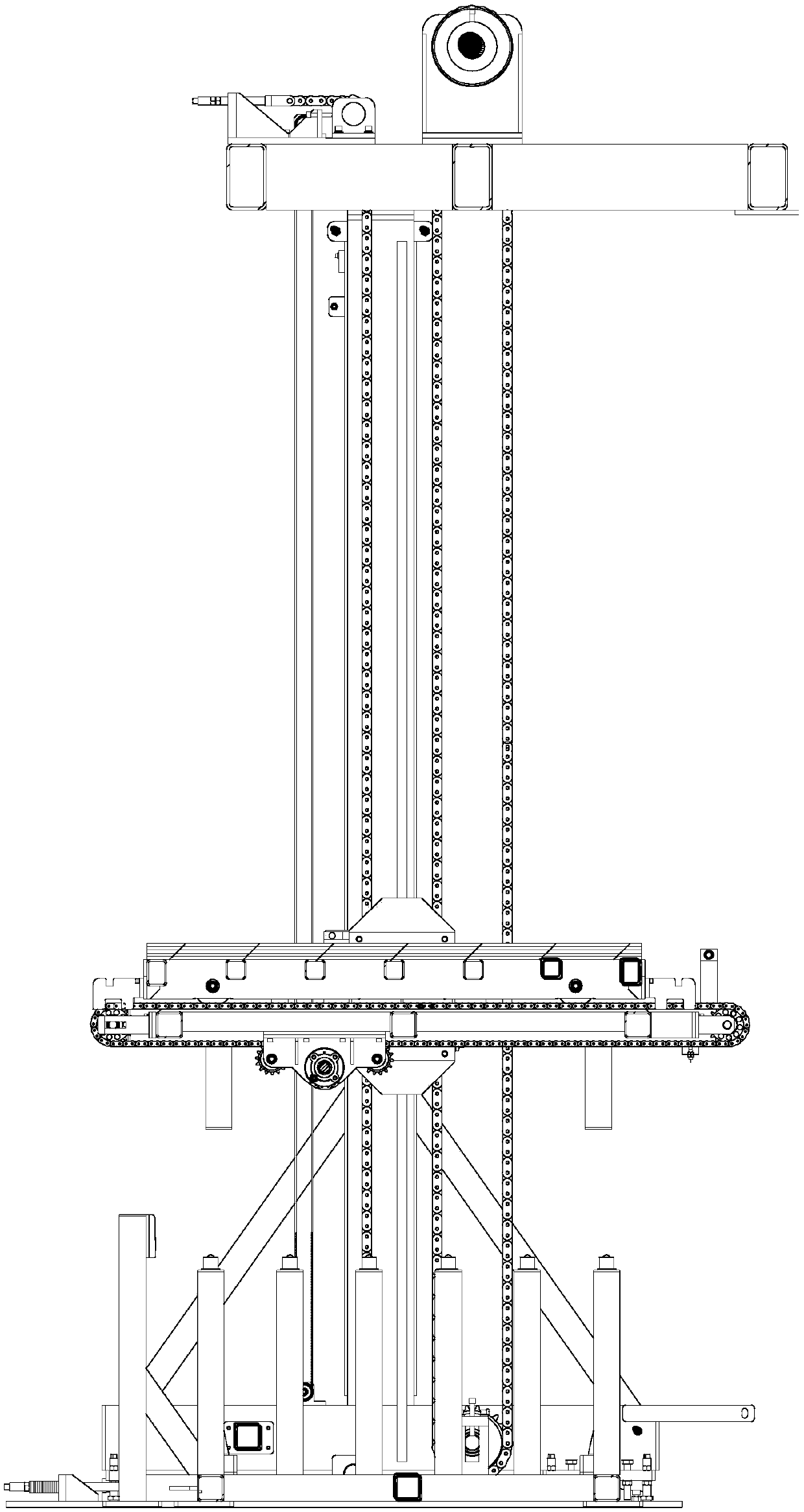

[0034] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0035] Such as Figure 1-3 As shown, a three-dimensional warehouse lifting device includes a support frame 1, a carrier seat 2, a pallet device 3, a lifting device 4 and a lifting drive device 5, and the top of the support frame 1 is provided with a lifting drive device 5, so that Both sides of the support frame 1 are respectively provided with a lifting device 4, and the lifting device 4 is driven by a lifting drive device 5. Under the action, it can move up and down, and the carrier board seat 2 is arranged under the pallet device 3 . The board lifting device can be used to lift the board and put it into the corresponding three-dimensional material warehouse. At the same time, the board taken out from the three-dimensional material warehouse can be transported to the bottom layer to realize the exchange of the board between each station. .

[0036] Such as Figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com