Tension adjusting roller for wire cutting machine

A tension adjustment and thread cutting machine technology, applied in thin material handling, transportation and packaging, winding strips, etc., can solve the problems of coil winding breakage, coil looseness, etc., to achieve a simple structure and avoid loose strips. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

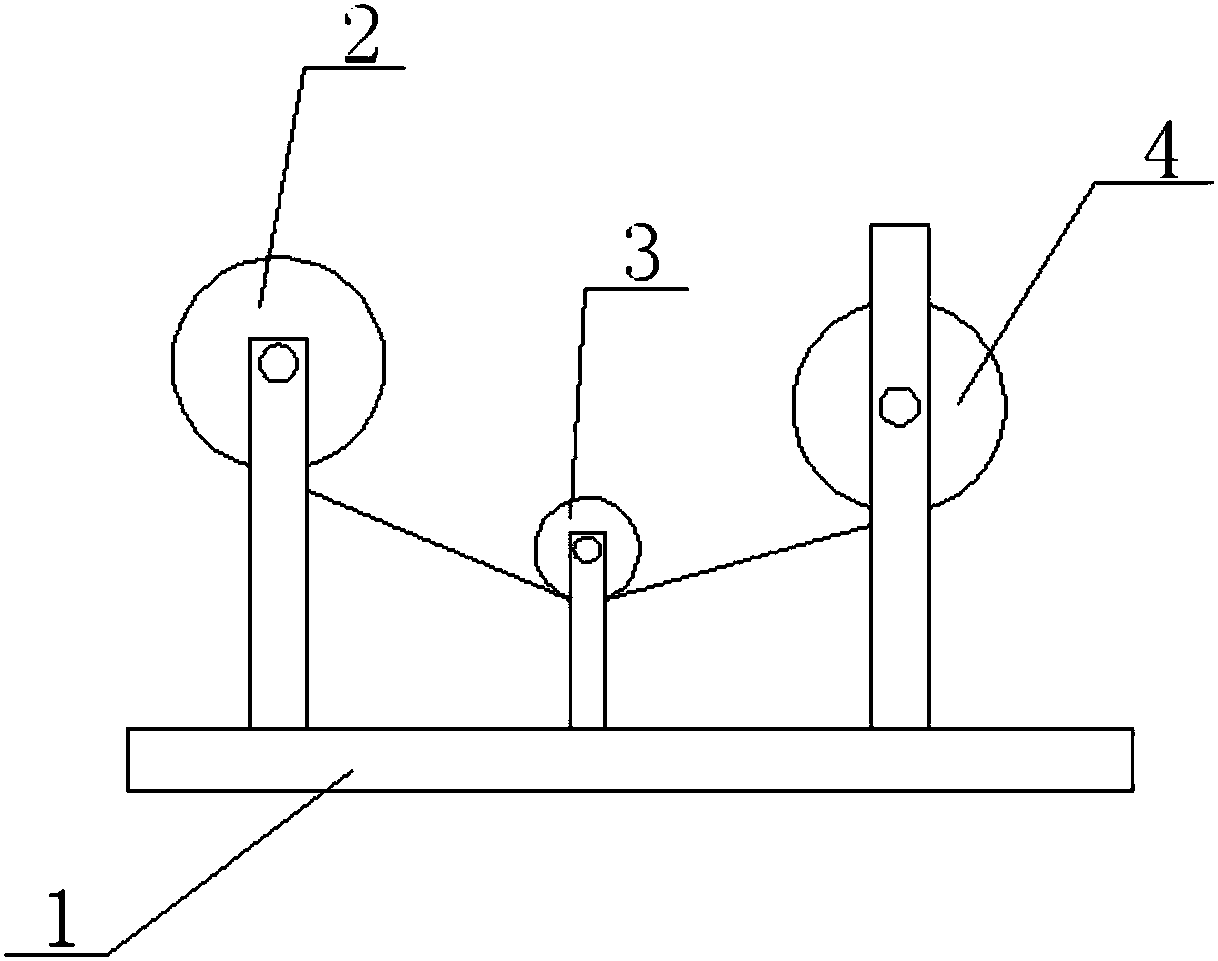

Embodiment 1

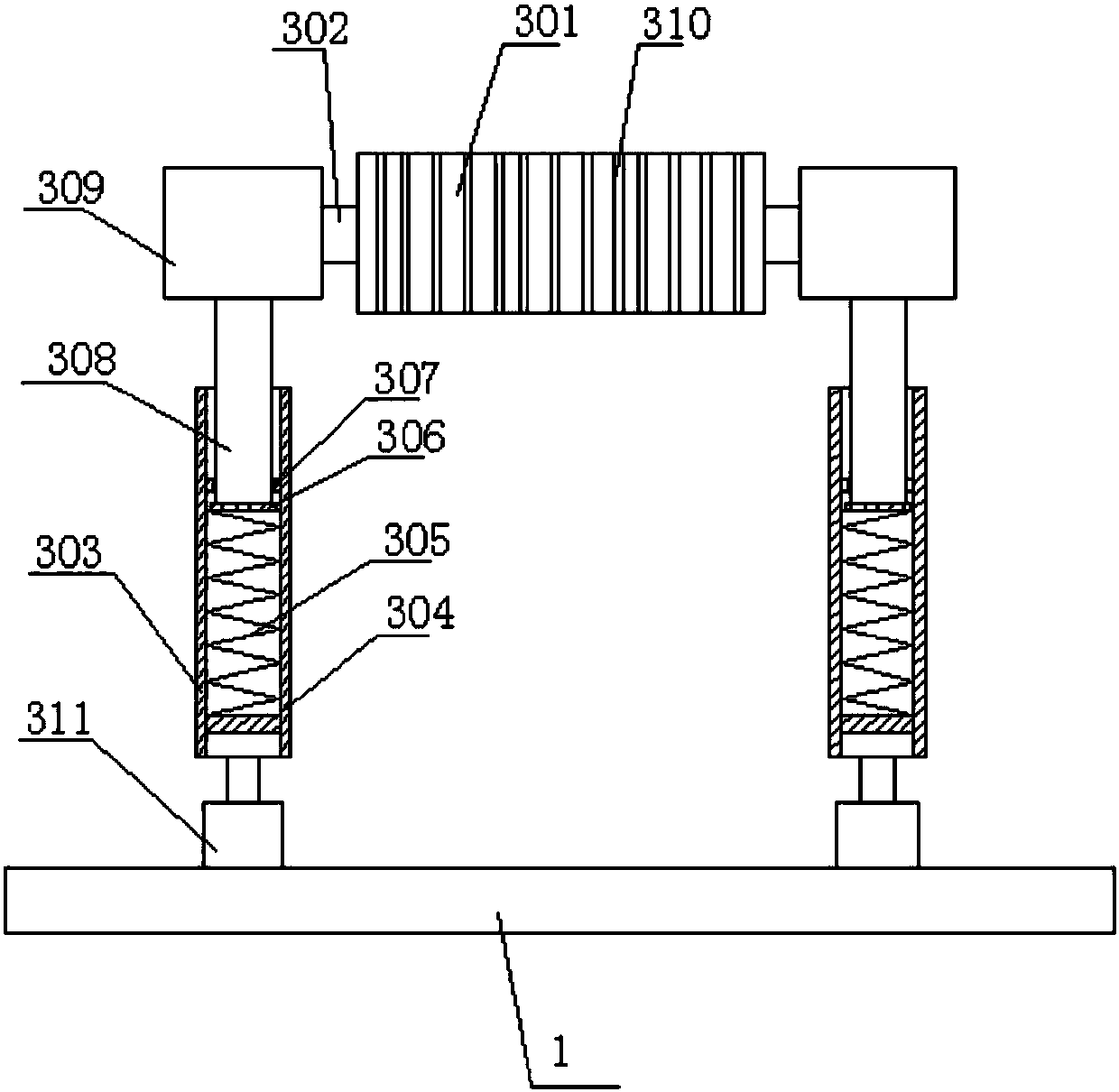

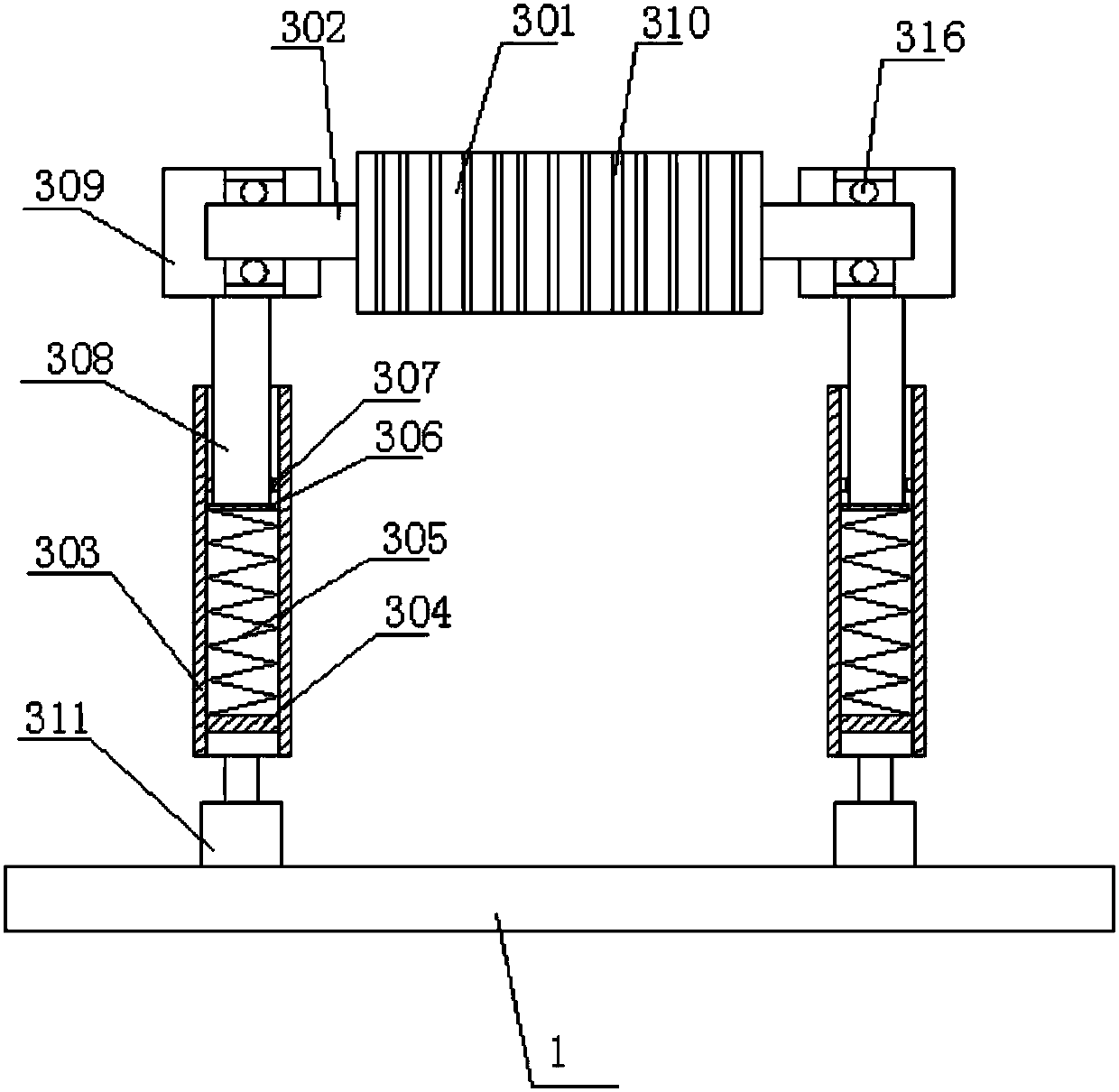

[0027] On the basis of Example 1, such as figure 2 or image 3 The winding tension adjusting roller 3 includes an adjusting roller body 301, a support tube 303 arranged on the base 1 and symmetrical to each other, a support plate 304 is fixed inside the support tube 303, and a stopper is provided above the support plate 304. plate 307, a compression spring 305 is arranged between the baffle plate 307 and the support plate 304, the upper end of the support tube 303 is connected with a support rod 308, and the lower end of the support rod 308 passes through the baffle plate 307 and is located in the compression The compression plate 306 provided on the upper end of the spring 305 is fixedly connected, the upper end of the support rod 308 is provided with a mounting seat 309 , and the adjusting roller rotating shaft 302 provided at both ends of the regulating roller body 301 is connected with the mounting seat 309 . The support plate 304, the baffle plate 307 and the compressio...

Embodiment 2

[0032] On the basis of Example 1, such as figure 2 , Figure 4 and Figure 5 The adjusting roller rotating shaft 302 provided at both ends of the adjusting roller body 301 is fixedly connected with the installation seat 309 .

[0033] The inner rubber layer 314 is set inside the annular wire passing groove 310, and an outer rubber layer 313 is set on the outer cover of the lower rubber layer 314, and multiple A ball 312, the end surface of the ball 312 is exposed through the outer rubber layer 313, and the ball 312 rolls relative to the outer rubber layer 313.

[0034] The balls 312 can roll in the outer rubber layer 313. When the strip is wound in the annular wire groove 310, due to the existence of the balls 313, the strip is on the wound balls to drive the balls to rotate, which is more effective. Less friction between the roller body and the strip reduces the winding force.

Embodiment 3

[0036] On the basis of Example 1, as image 3 and Figure 6 The adjusting roller rotating shaft 302 provided at both ends of the adjusting roller body 301 is connected with the mounting seat 309 through a bearing 316 . Using the bearing 316 for connection can effectively reduce the friction between the adjusting roller body 301 and the mounting seat 309 during the rotation process.

[0037] Further, in order to prevent static electricity from being generated during differential winding, a rubber pad 315 is sheathed in the annular wire passing groove 310 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com