Special-shaped and multi-standard cigarette product trademark picking, conveying, glue spraying, embossing and embossing device

A technology with multiple specifications and trademarks, which is applied in the field of glue spraying, conveying, stencil stamping devices, and trademark picking of special-shaped multi-specification cigarette products, can solve the problems of inability to meet the fast switching of trademarks of different specifications, low production and processing efficiency, and high labor costs. The effect of shortened conversion switching time, easy maintenance, and high precision of motion control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

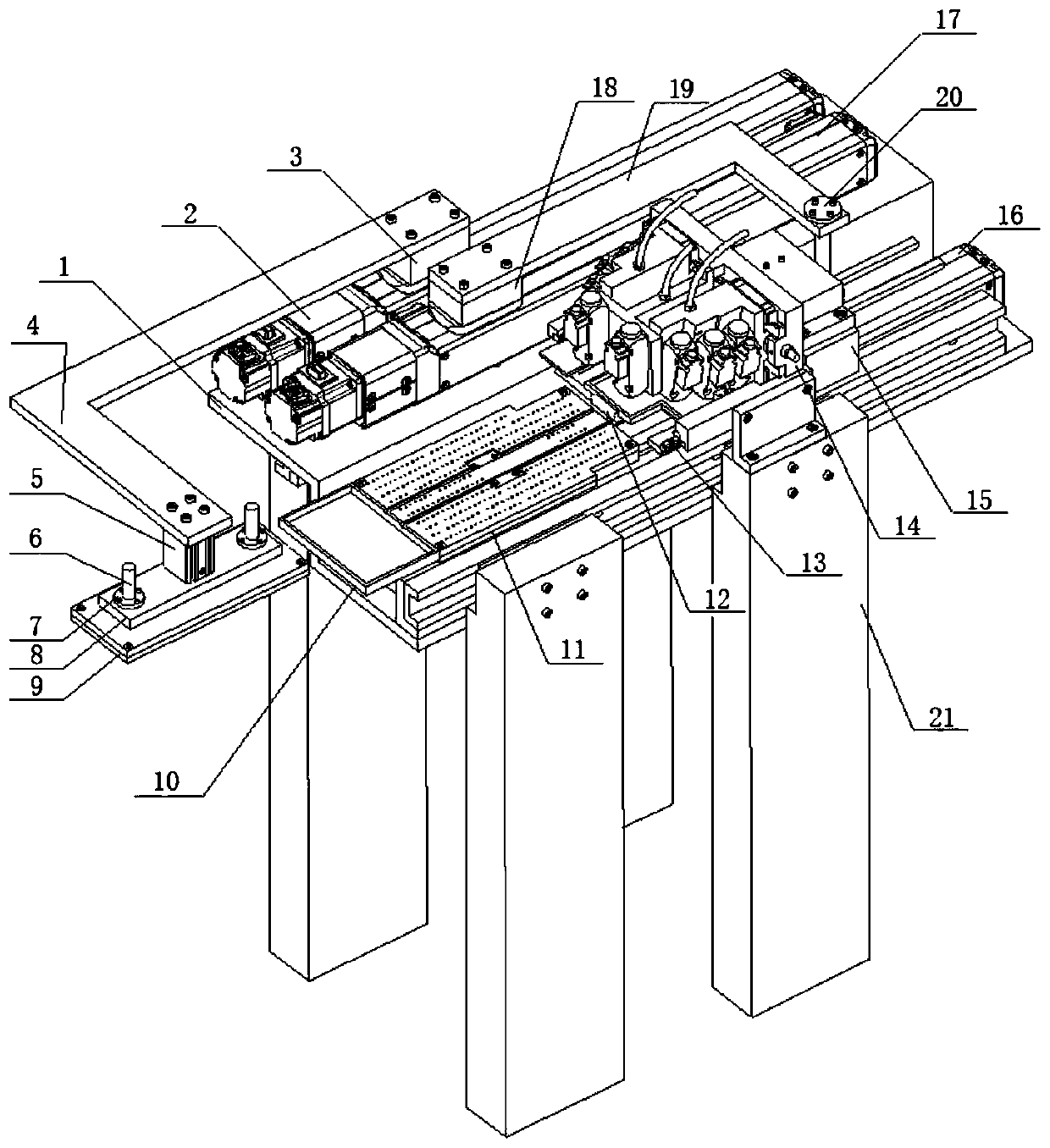

[0056] Such as figure 1 As shown, the device for picking up, conveying, glue spraying, and embossing the trademarks of cigarette products with different shapes and specifications includes a Z-shaped bottom plate 1, a trademark picking mechanism, a trademark conveying suction plate 11, a trademark pressing board 12, and a glue spraying mechanism 14. Stamping mechanism 15, trademark conveying electric cylinder 16, trademark pushing mechanism.

[0057] A trademark picking mechanism and a trademark pushing mechanism are installed on the upper plane of the Z-shaped bottom plate 1 .

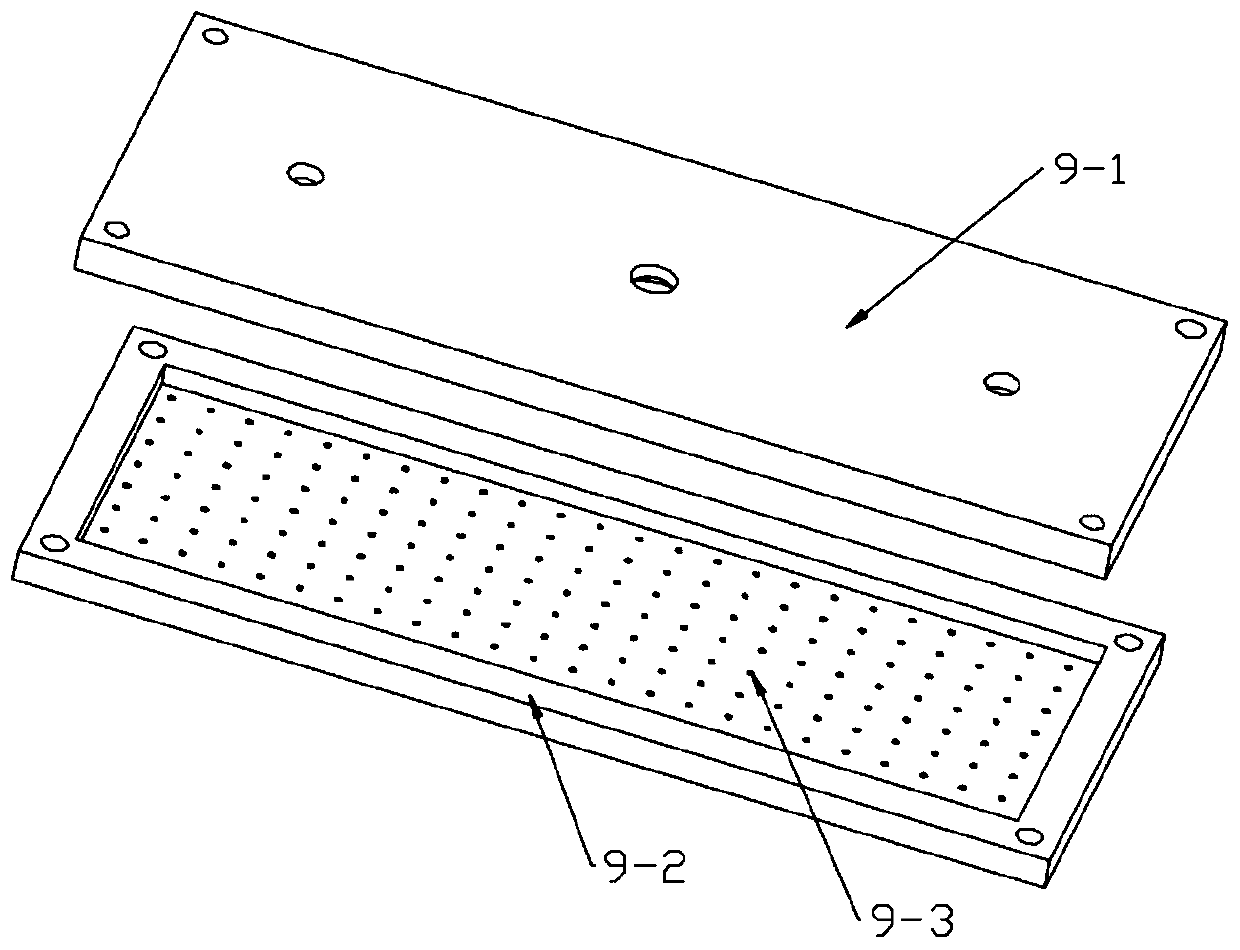

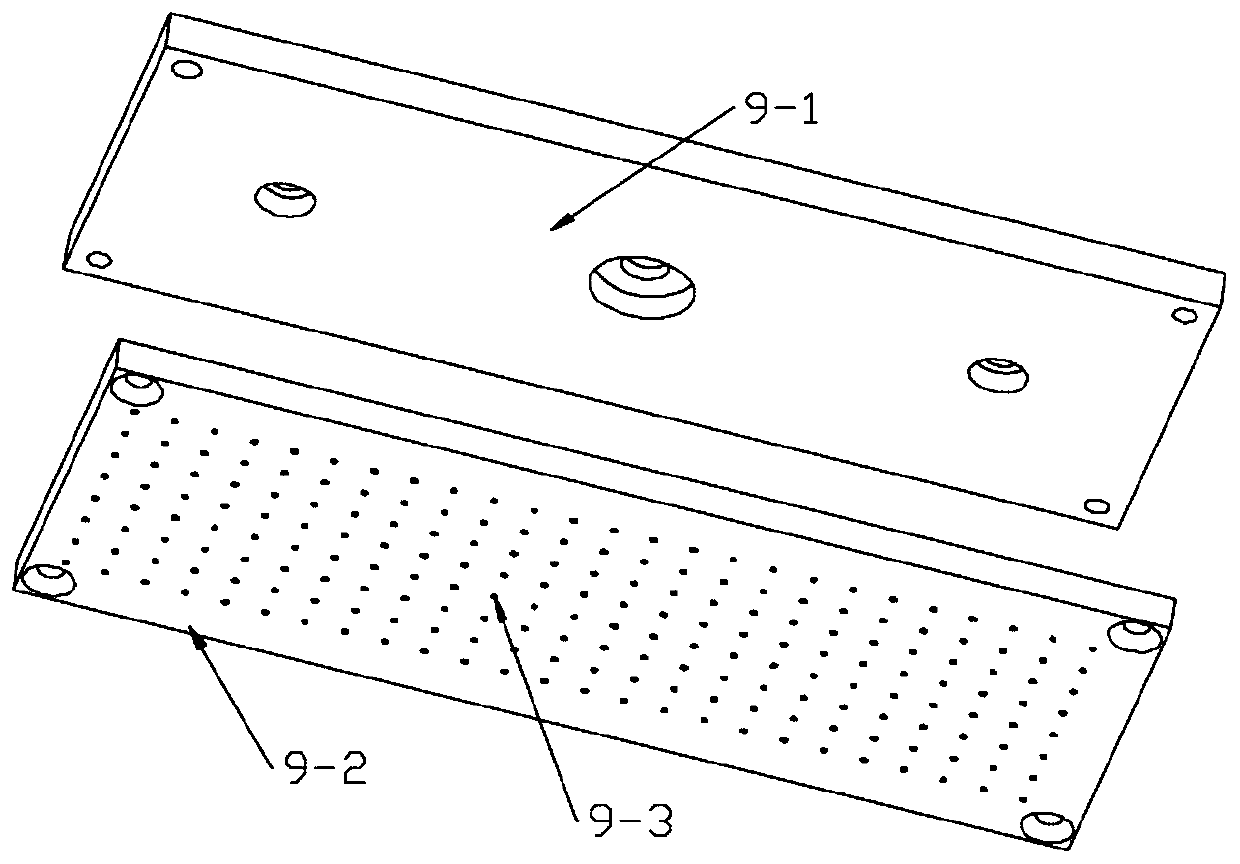

[0058] The trademark picking mechanism includes a trademark picking electric cylinder 2, a trademark picking arm connecting block 3, a trademark picking arm 4, a trademark picking cylinder 5, a trademark picking air suction plate 9, and the trademark picking electric cylinder 2 is installed on the Z-shaped bottom plate 1. On the upper plane, one end of the trademark pickup arm 4 is installed on the sl...

Embodiment 2

[0077] On the basis of Embodiment 1, a trademark picking cylinder mounting plate 8 is installed on the front end of the cylinder body of the trademark picking cylinder 5, and a linear bearing 7 is respectively installed on the front and rear symmetrical positions of the trademark picking cylinder mounting plate 8, and each linear bearing 7 A trademark pick-up guide rod 6 is provided, and the lower ends of two trademark pick-up guide rods 6 are connected with the trademark pick-up suction plate 9 . When the trademark pick-up cylinder 5 drives the trademark pick-up air suction plate 9 to pick up the trademark S, the trademark pick-up guide rod 6 can make a linear motion in the linear bearing 7, which guides the movement of the trademark pick-up air suction plate 9, and improves the trademark pick-up air suction plate. 9 Stability of work.

Embodiment 3

[0079] On the basis of Embodiment 1 or Embodiment 2, the glue spraying mechanism 14 is equipped with a glue wiping mechanism 13 . The glue-wiping mechanism 13 includes a glue-wiping electric cylinder 13-1, a glue-wiping slider 13-2, a glue-wiping electric cylinder slider connection block 13-3, a rubber blocking plate 13-4, and a cross roller guide rail 13-5 , rolling guide rail 13-6, connector 13-7, rolling guide rail slider 13-8, sponge bottom plate 13-9, sponge 13-10, and the described glue wiping electric cylinder 13-1 is installed on the Z-shaped bottom plate 1 On the back side of the vertical plate, one side of the rubber baffle plate 13-4 is installed on the slider of the rubber wiping electric cylinder 13-1 through the rubber wiping slider 13-2, and the upper plane of the Z-shaped bottom plate 1 crosses the vertical board There is a rectangular groove at the edge of the rubber baffle 13-4, and after passing through the rectangular groove, it extends to the bottom of the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com