Steel rail noise reduction damper and making and mounting method and vibration absorbing and noise reduction method

A technology of vibration reduction and noise reduction, damper, applied in the direction of track, road, building, etc., can solve the problems of rail vibration and radiation noise to be substantially improved, increase sleeper noise, noise increase, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

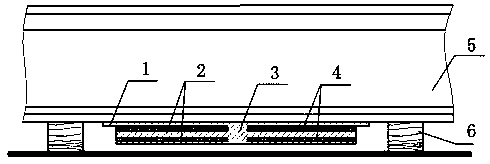

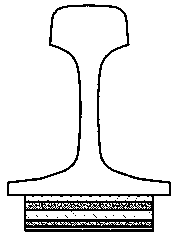

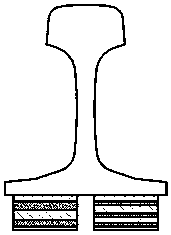

[0063] Please refer to Figure 1 to Figure 6 , a rail noise reduction damper, comprising a mounting plate 1, a resonant plate 2, a connecting body 3 and an elastic damping layer 4. The left and right sides of the connecting body are connected with a mounting plate and a resonance plate, one end of the mounting plate is connected to the top of the side of the connecting body, the resonance plate is located directly below the mounting plate, and one end of the resonance plate is connected to the side of the connecting body; the resonance plate An elastic damping layer is filled between the mounting plate and the mounting plate. Both the mounting plate and the resonance plate are arranged horizontally or roughly horizontally, and the other ends of the mounting plate and the resonance plate are suspended to form a cantilever beam structure; the other ends of the mounting plate protrude from the other end of the resonance plate; the left side of the connecting body and The mountin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com