Multifunctional supporting support device for prefabricated building

A multifunctional and prefabricated technology, which is applied to the preparation of building components on site, construction, building construction, etc., can solve the problems of material waste, labor, and potential safety hazards, and achieve firm connection, reduce construction costs, and save energy. The effect of the lower space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Before using the multifunctional support jacking device for prefabricated buildings of the design structure, the well-prepared device of the present invention is assembled as a backup according to the installation requirements.

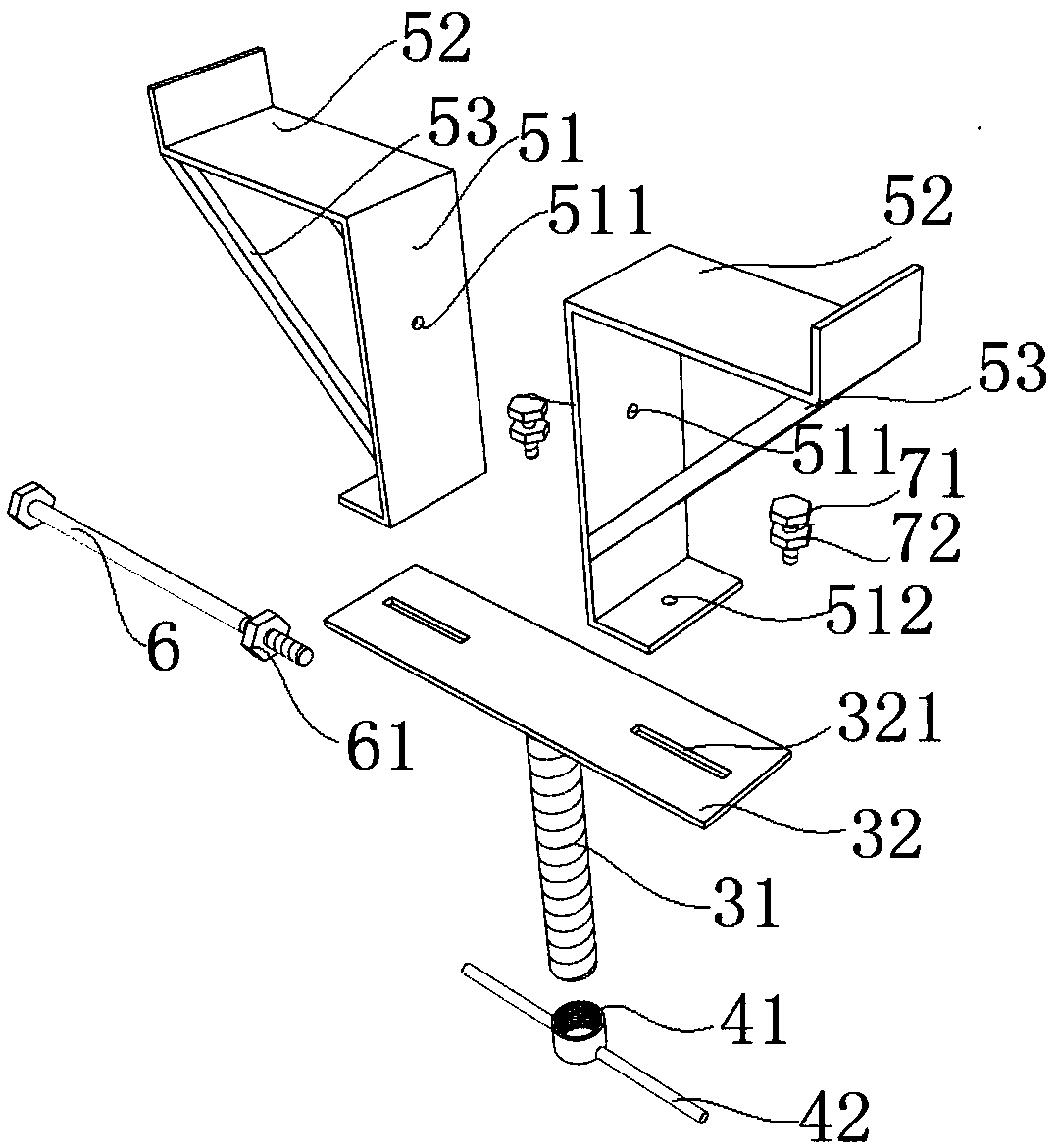

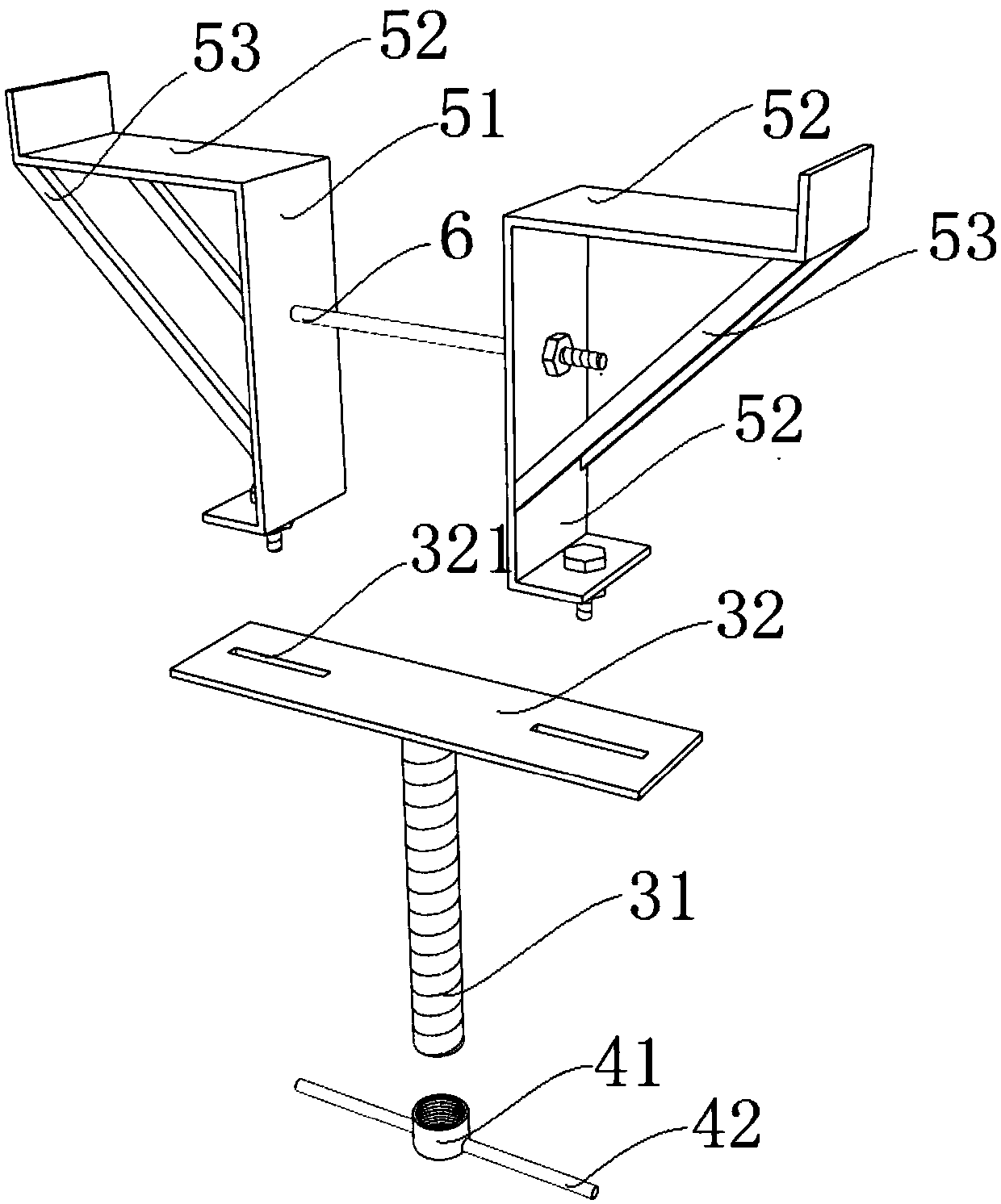

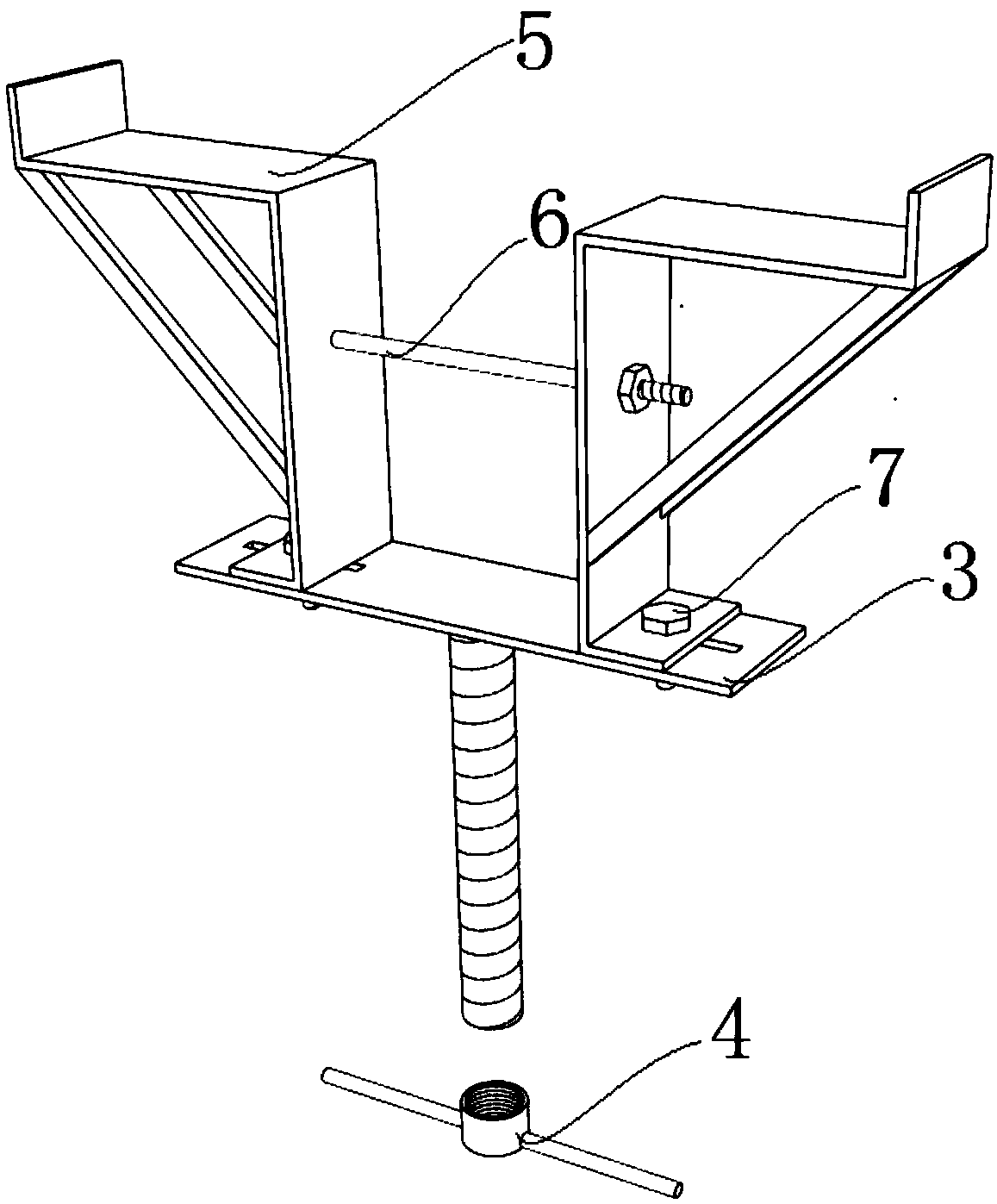

[0055] Prefabricated beams reserve perforations according to the required number and position of support. Before use, the staff arranges multiple support jacking devices in rows according to the needs of the actual construction situation. Before hoisting the beams, place multiple According to the position of the reserved hole on the beam, it is fixed and placed in advance, and then the prepared support jacking device is transported to the construction site for installation and use. The lower end and the support column 1 are screwed firmly, and then the adjustable support jacks 5 on both sides of the beam 9 are adjusted according to the needs of the actual work. When adjusting, according to the size of the beam 9, adjust the distance between the ...

Embodiment 2

[0058] A multifunctional support jacking device for a prefabricated building of the design structure, before being used for construction, firstly assemble the well-prepared device of the present invention as a backup according to the installation requirements,

[0059] During installation, first determine the distance between the two connecting plates 51 according to the width of the prefabricated beam, and then use bolts 72 to fix the baffles on both sides on the installation jack 32 through the bolt holes 512. Then, the adjusting member 41 is twisted and placed on the adjustable lifting screw 31 to be preliminarily pre-installed.

[0060] According to the above steps, the installation of the adjustable support jacking device can be completed; before use, it is necessary to prepare the assembled adjustable jacking device, triangular support frame, and scaffolding board, and then place the beam according to the position where the prefabricated beam is to be placed. The positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com