Coupling shaft mechanism

A shaft coupling and shaft sleeve technology, applied in the direction of shaft couplings, elastic couplings, mechanical equipment, etc., can solve the problems of complex work sites, reduced service life of mechanical equipment, easy damage to shafts and bearings, and reduce concentricity Requirements, avoid impact, improve the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

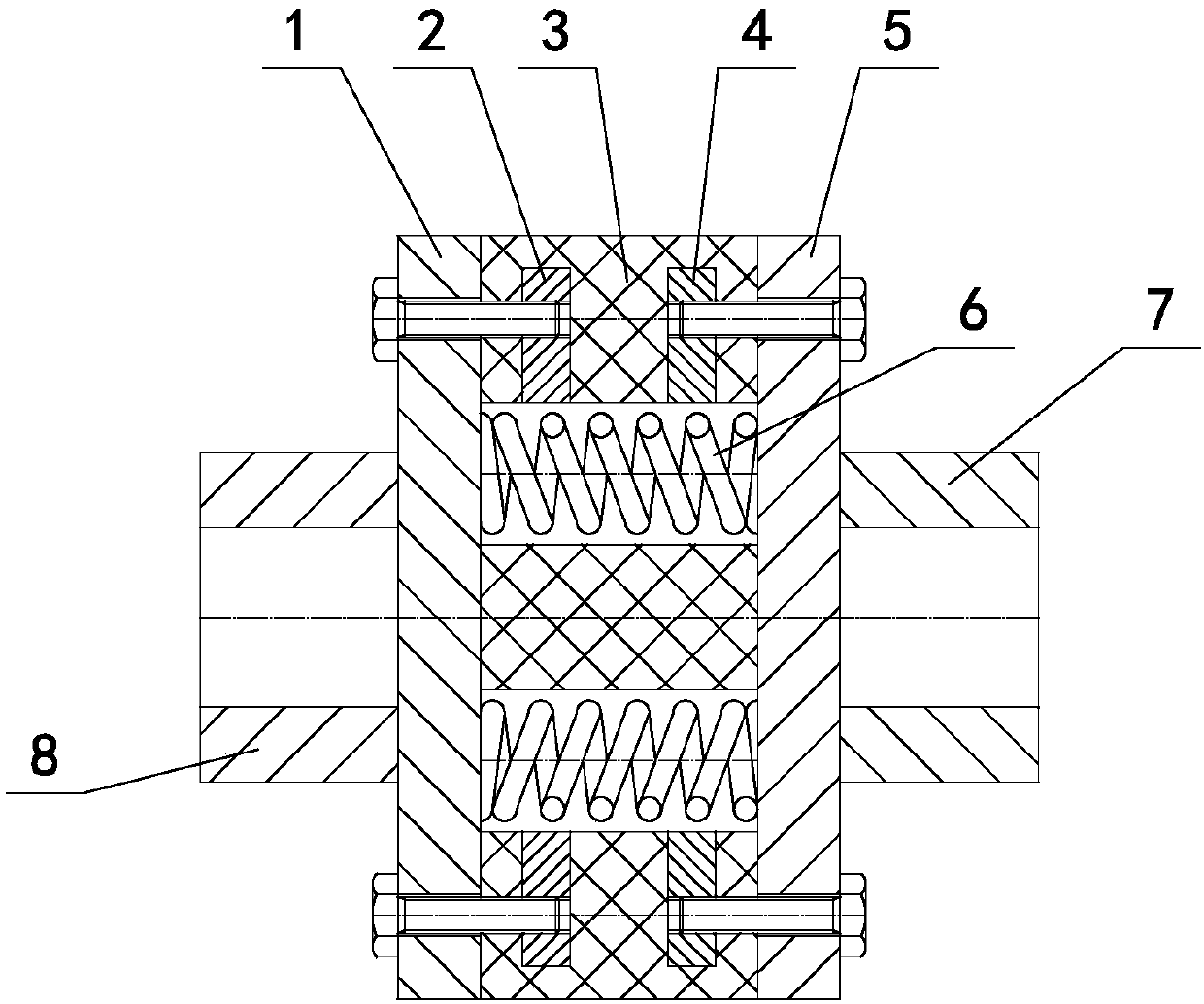

[0015] Such as figure 1 As shown, the coupling mechanism includes a vertically arranged first connecting plate 1, a second connecting plate 5 is vertically arranged on the right side of the first connecting plate 1, and the first connecting plate 1 and the second connecting plate 5 An elastic block 3 is arranged between them, a first washer 2 is vertically arranged in the elastic block 3, a second washer 4 is vertically arranged in the elastic block 3 on the right side of the first washer 2, and the first washer 2 is connected by bolts On the first connecting plate 1, the second washer 4 is connected to the second connecting plate 5 by bolts, and a first shaft sleeve 8 is horizontally arranged on the left side of the first connecting plate 1, and on the right side of the second connecting plate 5 A second shaft sleeve 7 is arranged horizontally, and the first shaft sleeve 8 and the second shaft sleeve 7 are located on the axis of the elastic block 3 .

[0016] In this embodim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com