Anti-vibration air pipe module

A pipe assembly and assembly technology, applied in the direction of pipe elements, pipes/pipe joints/pipe fittings, passing elements, etc., can solve the problems of large shock vibration, influence of road pressure pulsation peak value, poor control accuracy, etc., and reduce the occurrence of cracks Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

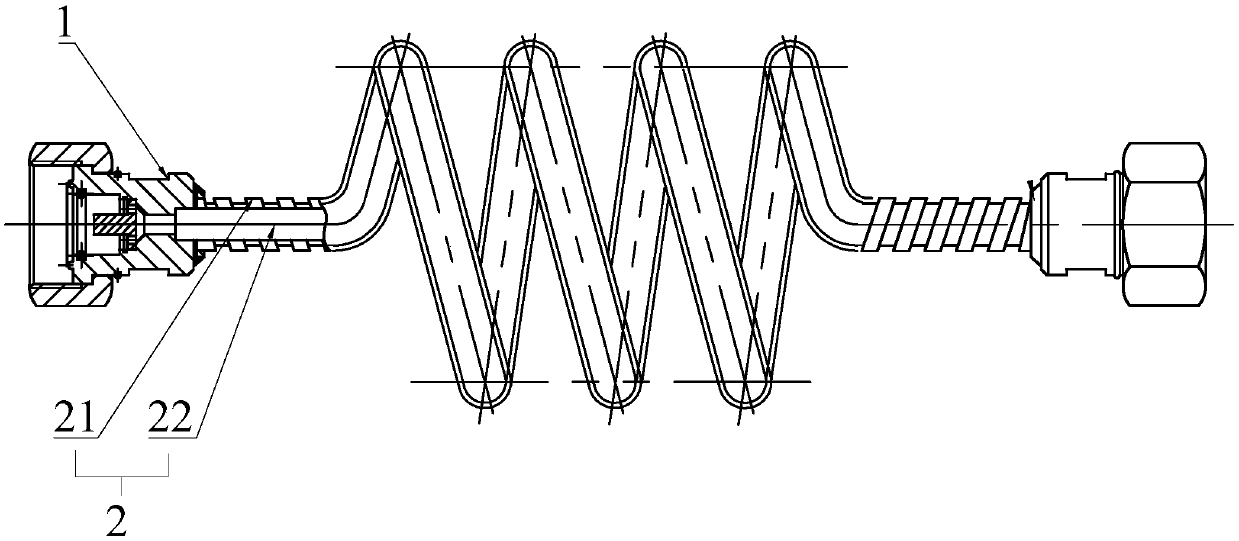

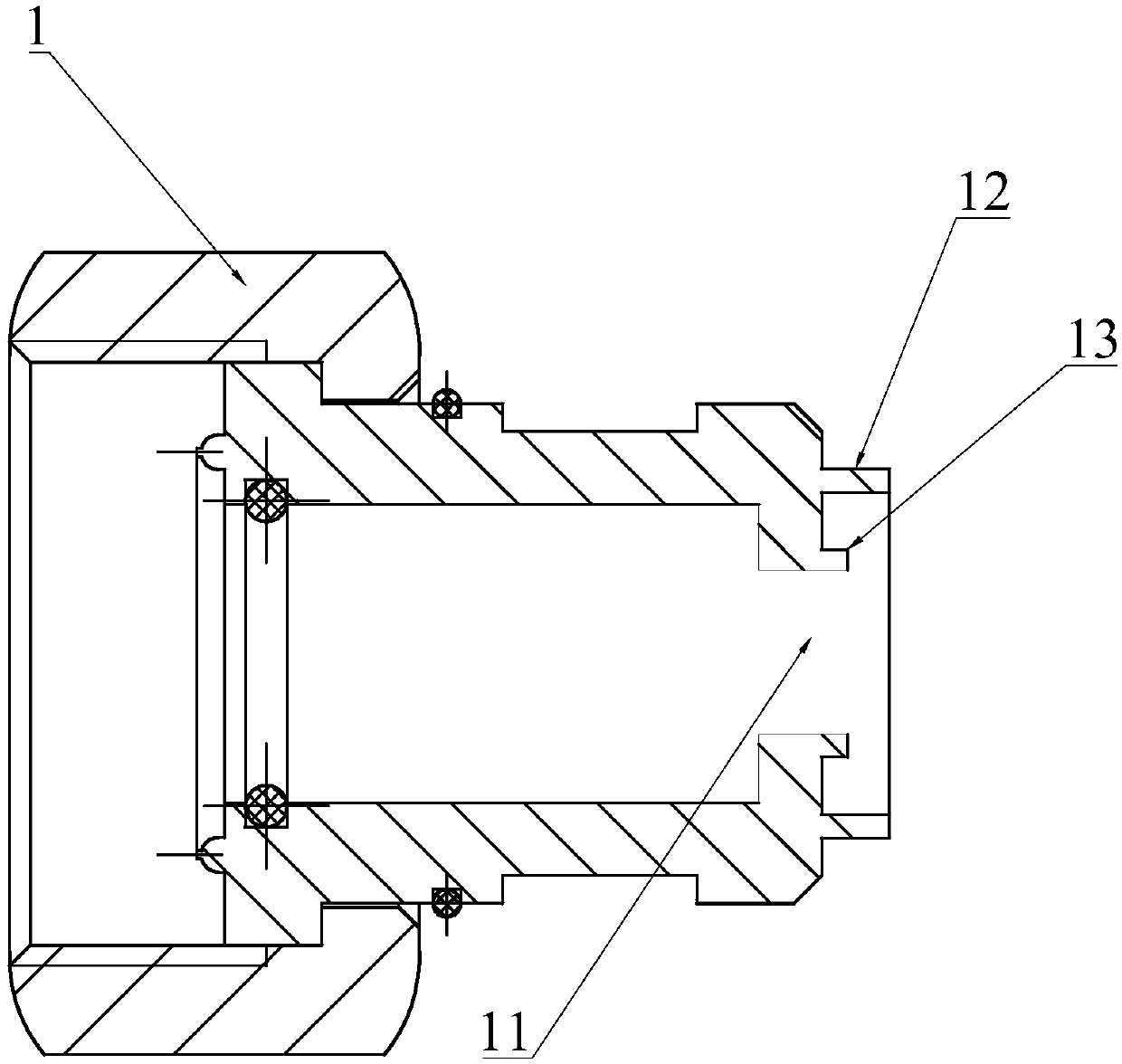

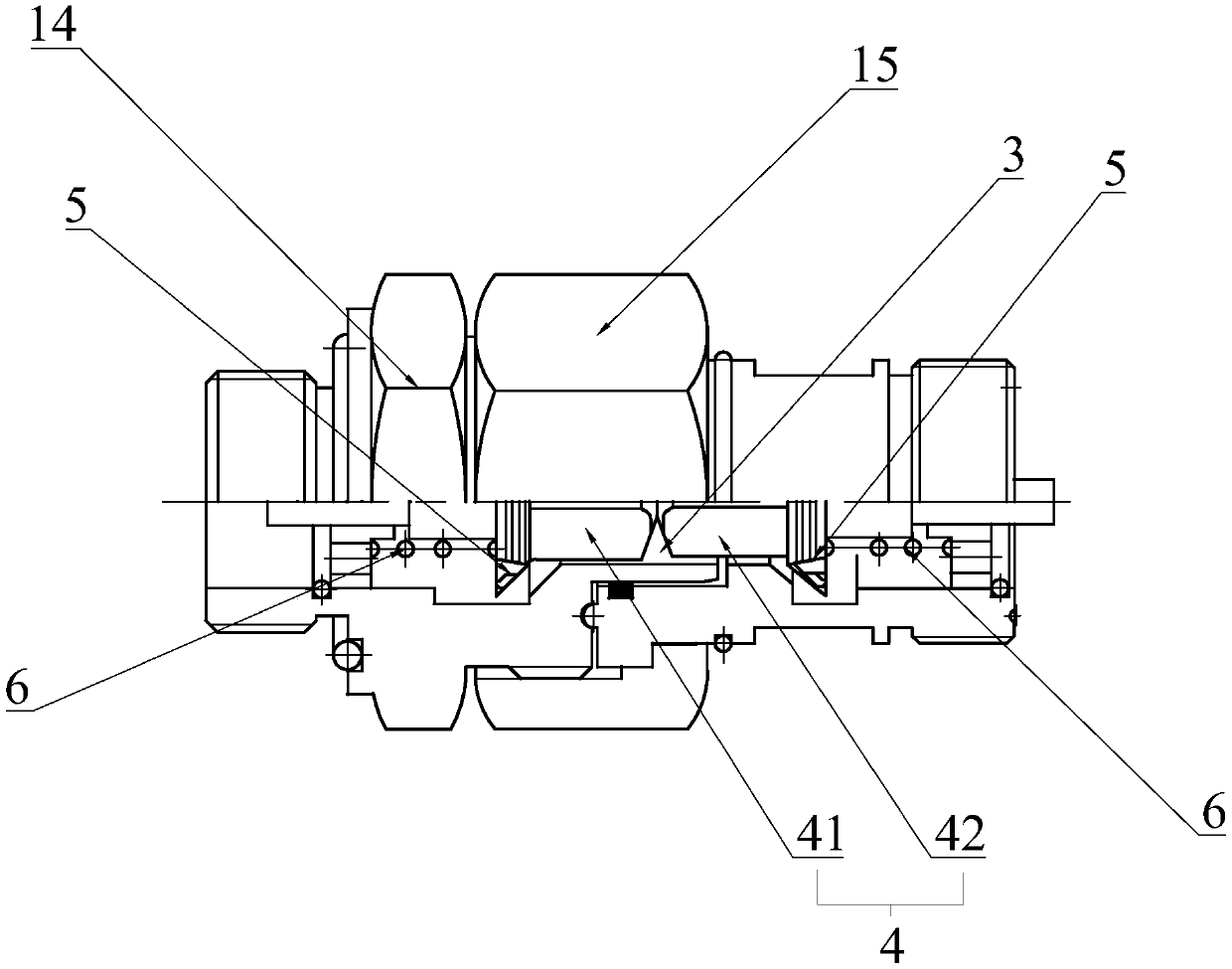

[0022] see figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, the anti-vibration air pipe assembly 2 of the present invention includes two joints and a pipe assembly 2 connected between the two joints. The pipe assembly 2 includes an outer hose 21 and several tubes arranged in the outer hose 21 Capillary 22, the joint is provided with a step hole 11, the capillary 22 is arranged in the step hole 11, the end face of the joint is provided with a first welding flange 12 for welding the outer hose 21, the step The edge of the hole 11 is provided with a second welding flange 13 for the capillary 22, and the capillary 22 is flexibly connected between two joints. By setting the capillary 22 and flexibly connecting between the two joints, the gas path can be connected The peak value of pressure pulsation is attenuated to the minim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com