Patents

Literature

41results about How to "Reduce weld cracking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

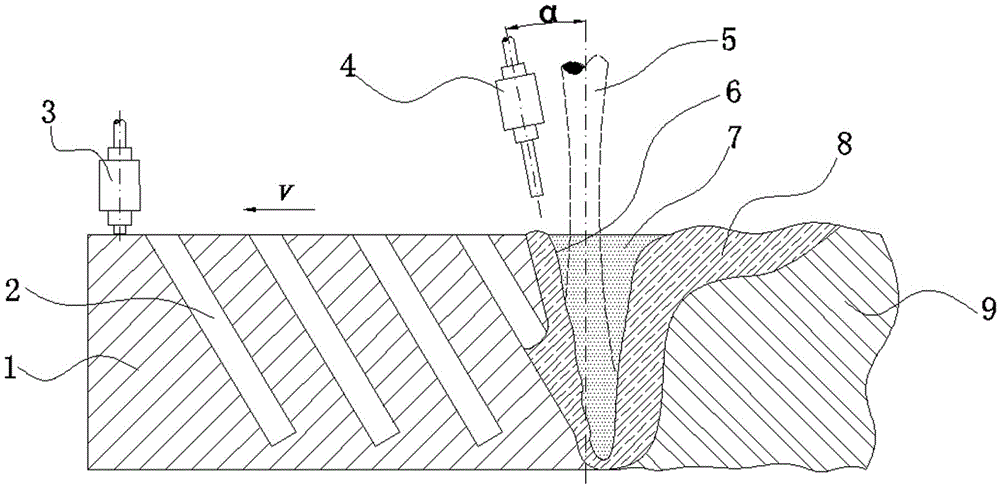

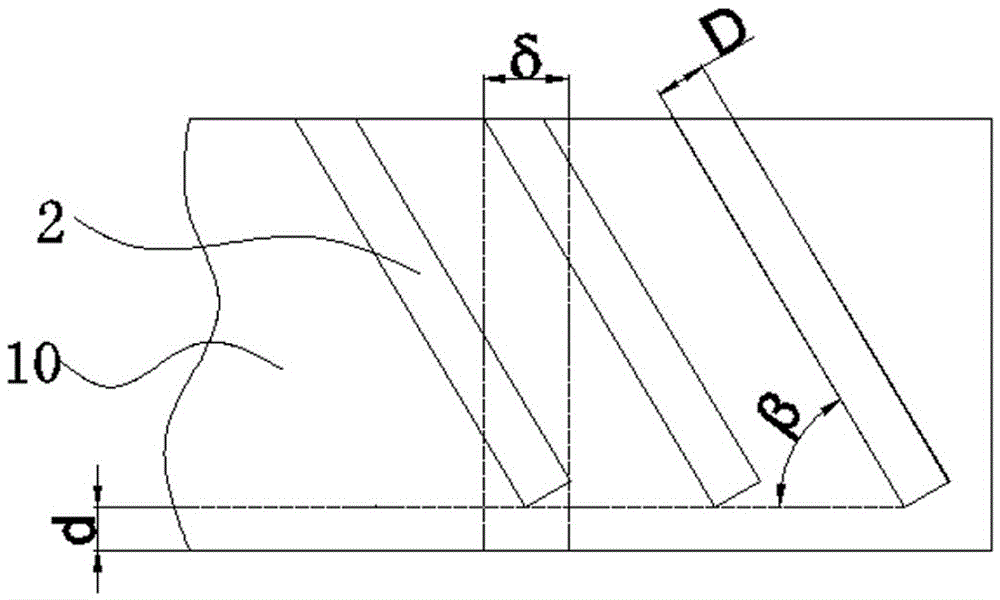

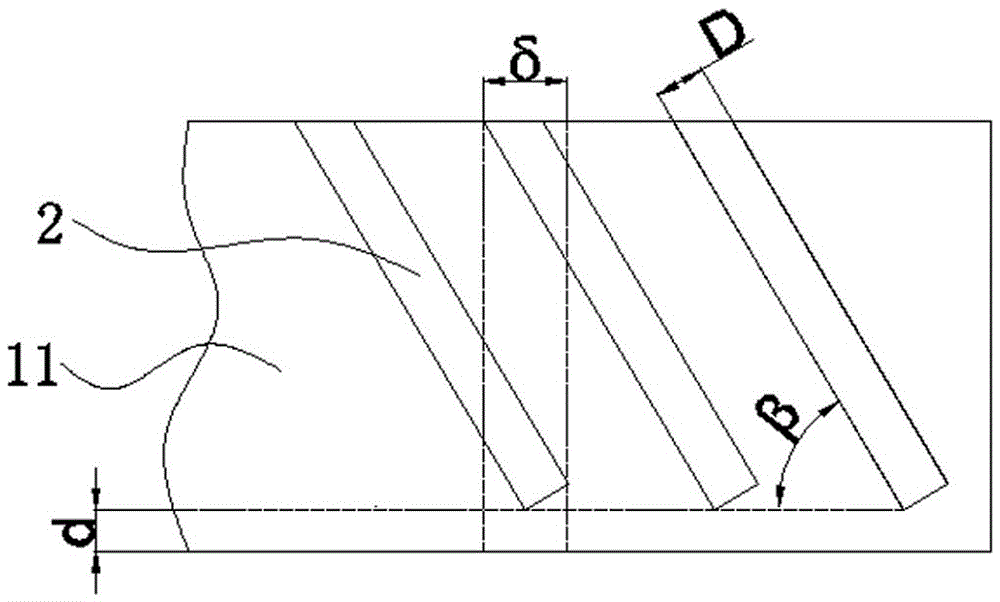

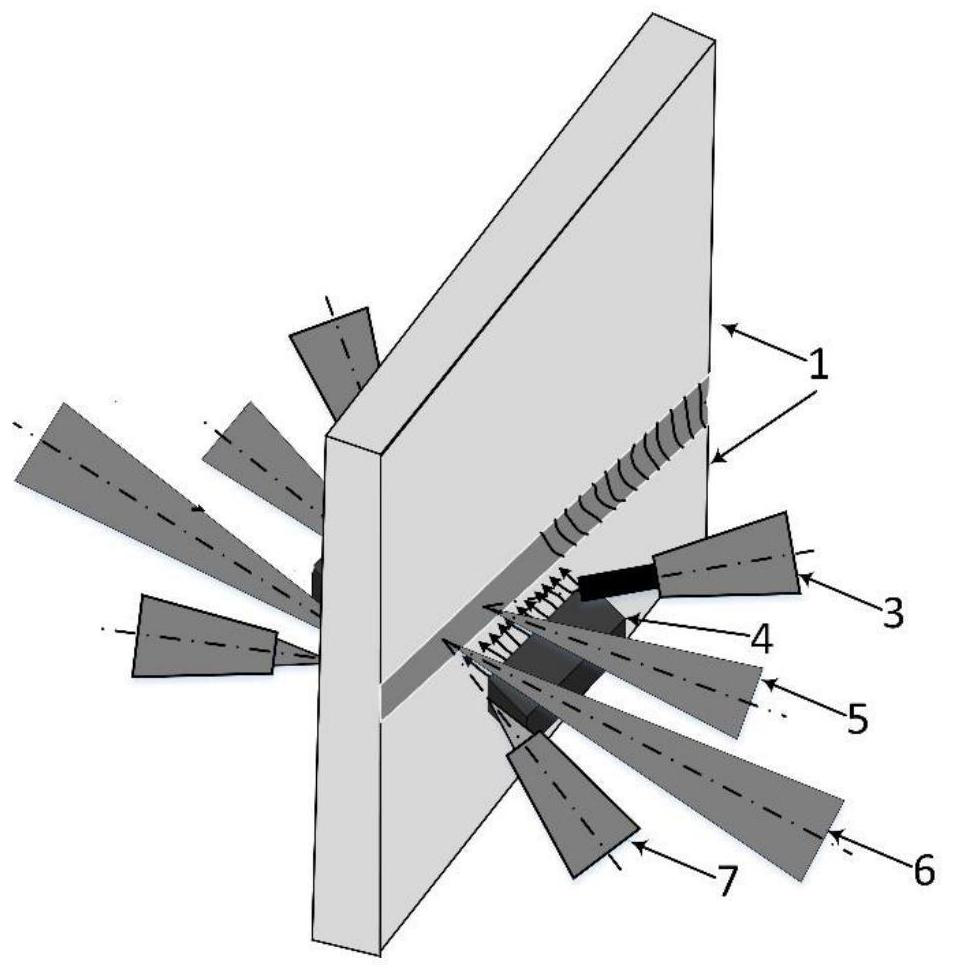

Method for deep penetration laser welding of plate under assistance of ultrasound

ActiveCN105583523AWide range of process parametersReduce crater depthWelding/soldering/cutting articlesMetal working apparatusSmall holeWeld bead

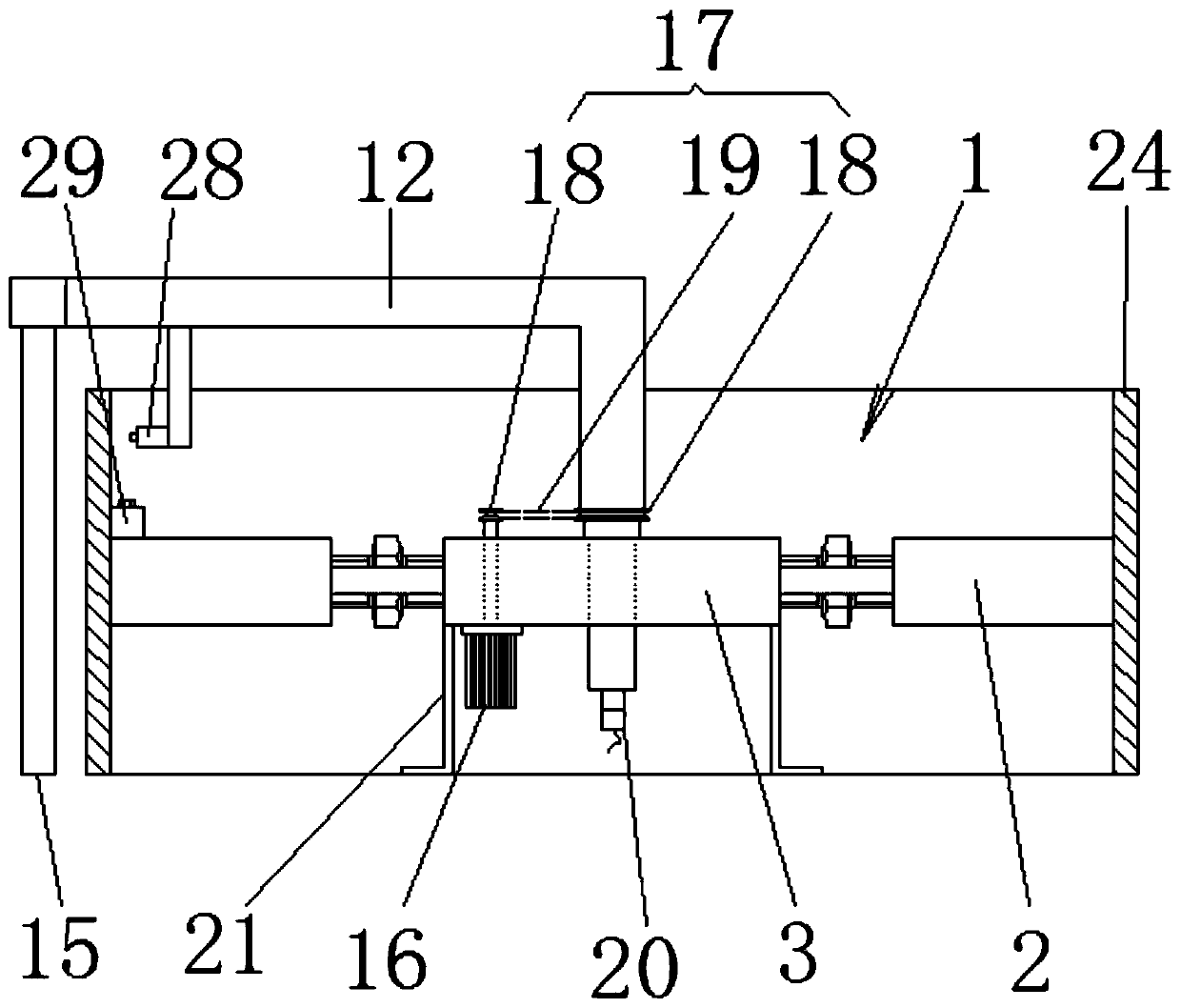

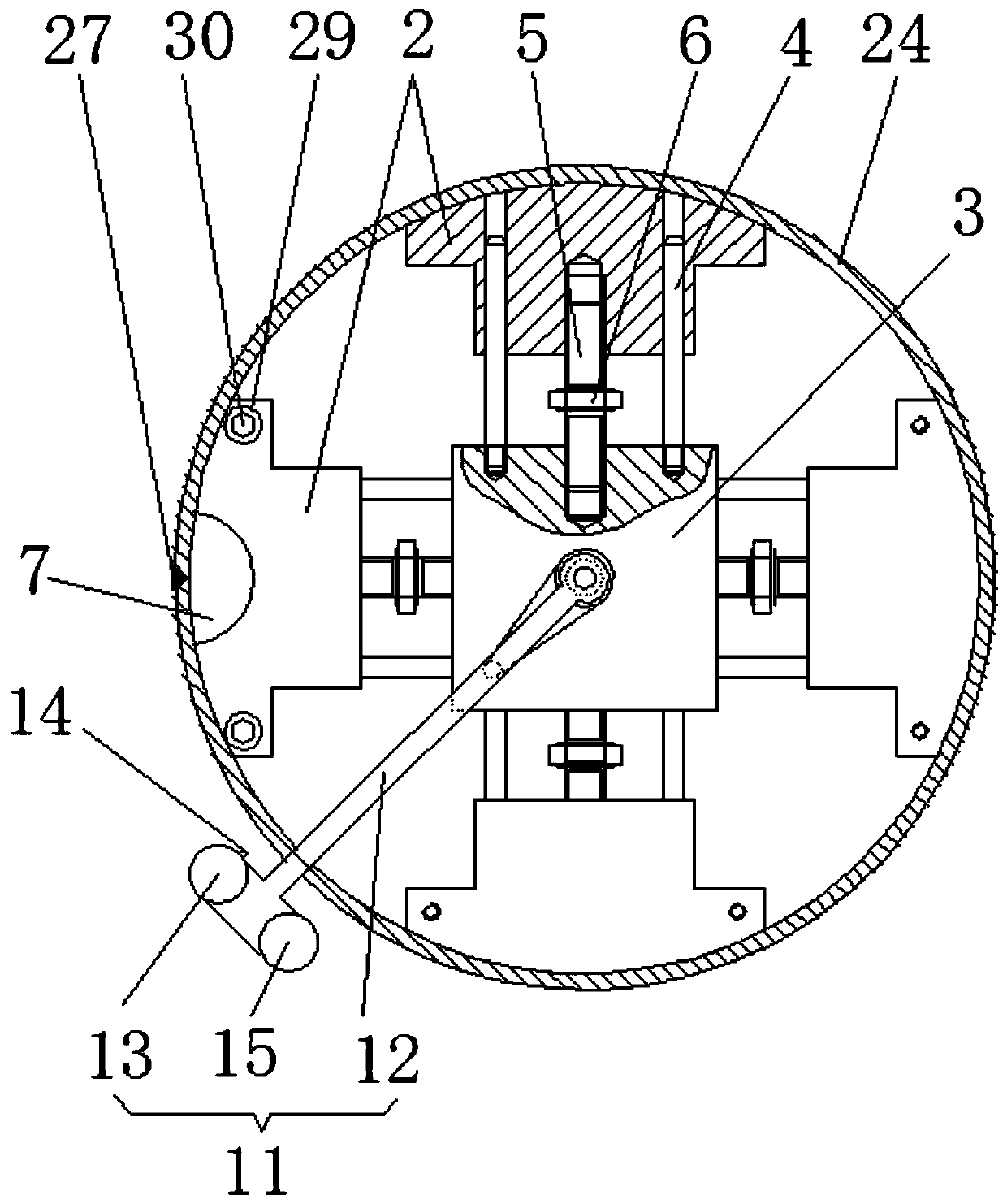

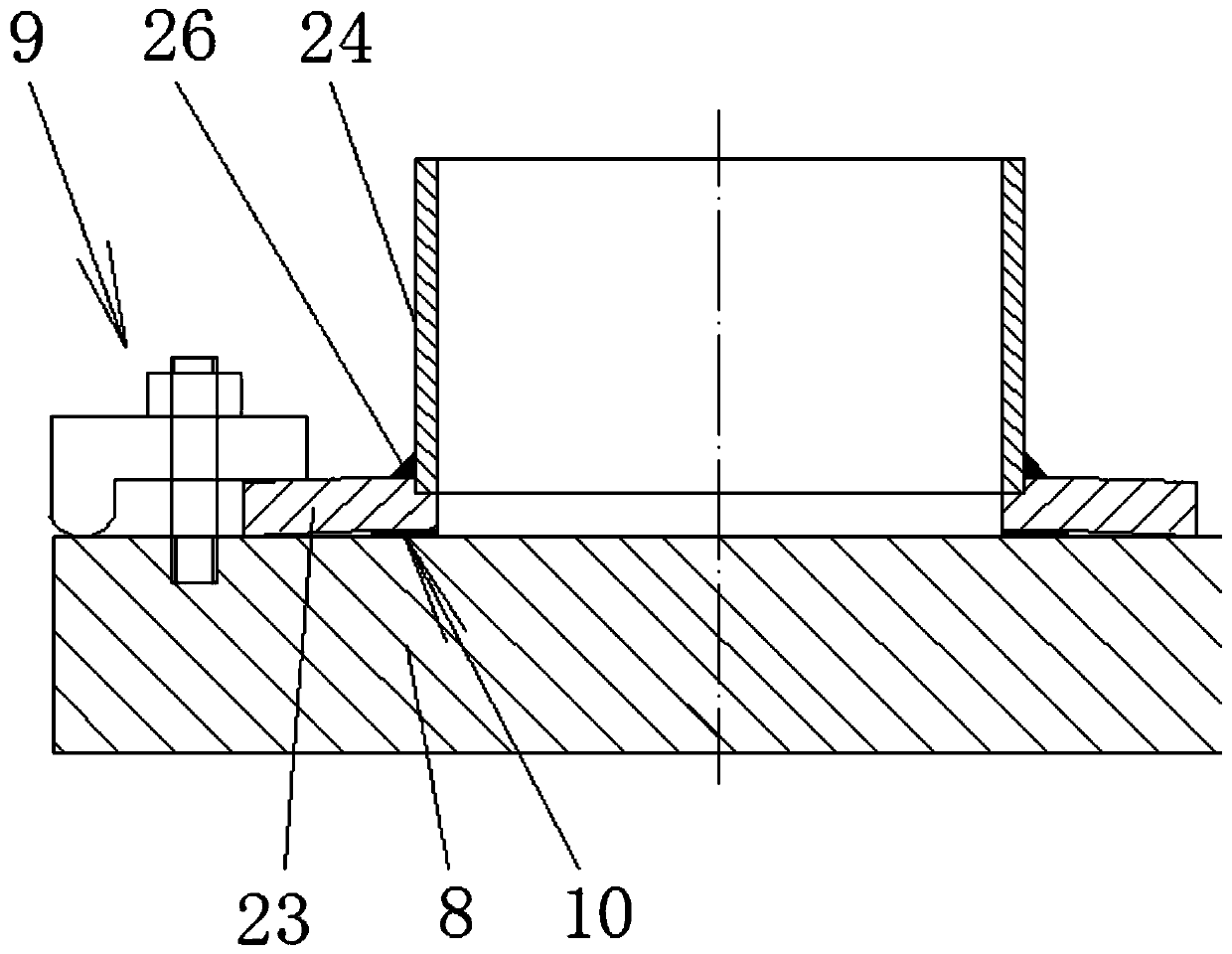

The invention relates to a method for deep penetration laser welding of a plate under the assistance of ultrasound. The method is characterized by comprising the following steps that firstly, first base metal (10) and second base metal (11) are machined to form butt joint end faces, and a series of inclined semicircular grooves are machined; secondly, the first base metal (10) and the second base metal (11) are in butt joint and are clamped, and a series of inclined blind holes are formed in a weld bead; thirdly, a first ultrasonic amplitude-changing rod (3) is pressed to the upper surface of a workpiece to be welded; fourthly, a second ultrasonic amplitude-changing rod (4) is fixed to one side of a laser welding head; fifthly, an ultrasonic generation device is started, the ultrasonic frequency is adjusted; sixthly, a laser beam (5) perpendicularly irradiates the upper surface of the workpiece, and the welding process is completed under continuous ultrasonic vibration; and seventhly, after welding is completed, ultrasonic vibration is maintained for 1-2 minutes. In the method, due to the pre-formed inclined blind holes and ultrasonic vibration, weld joint root leakage caused by molten pool downward flowing driven by local evaporation back flushing pressure of the front edge walls of the small holes is avoided.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

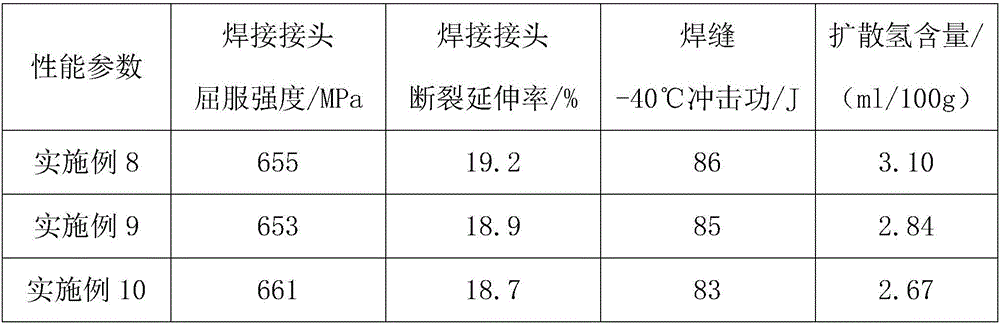

Coated welding wire for welding low-alloy high-strength steel and manufacturing method

InactiveCN106736013AMeet welding requirementsHigh strengthWelding/cutting media/materialsSoldering mediaHigh intensityImpurity

The invention discloses a coated welding wire for welding low-alloy high-strength steel. The coated welding wire comprises a welding wire substrate and a coating which coats the surface of the welding wire substrate, wherein the welding wire substrate is made from the following components in percentage by weight: 0.029 to 0.041 percent of Ti, 0.01 to 0.015 percent of Al, 0.083 to 0.11 percent of Nb, 0.1 to 0.15 percent of C, 0.2 to 0.3 percent of Cr, 0.3 to 0.5 percent of Si, 0.01 to 0.03 percent of N, 1.4 to 1.7 percent of Ni, 0.1 to 0.6 percent of Mo, less than or equal to 0.002 percent of P, less than or equal to 0.002 percent of S, and the balance of iron and unavoidable impurities, wherein as specified by the following formula, K is between 0.013 and 0.032, K=29[Ti]+52[Al]+27[Nb]-100[N]; [Al], [Ti], [Nb] and [N] represent the weight percentage contents of Al, Ti, Nb and N in the welding wire substrate respectively. The invention further discloses a manufacturing method of the coated welding wire for welding the low-alloy high-strength steel. By adopting the coated welding wire, high strength of welding metal is ensured, the welding performance of the low-alloy high-strength welding wire is improved finitely, the occurrence of cold cracks is controlled, a low splashing rate is achieved, and the welding requirement of the high-strength low-alloy steel is met.

Owner:安徽飞弧焊业股份有限公司

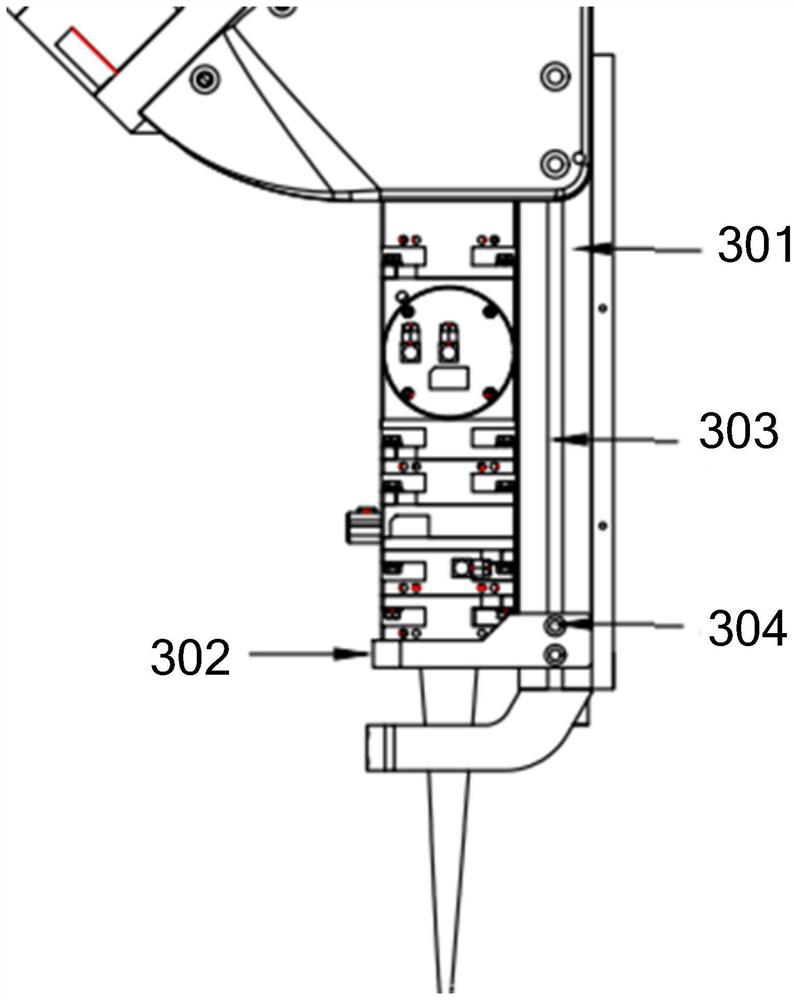

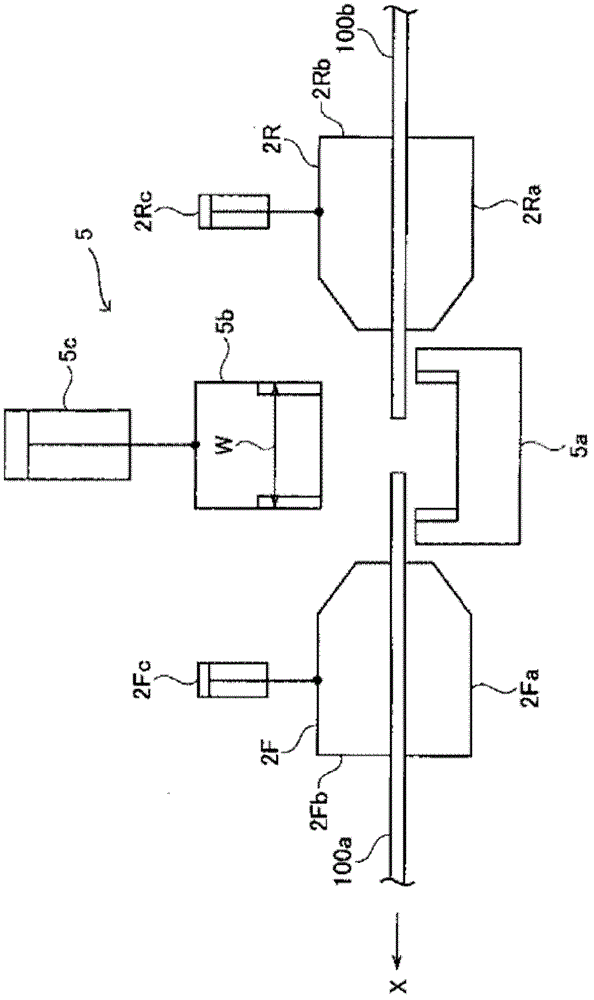

Thick plate laser arc composite double-sided synchronous horizontal welding method and device

ActiveCN114012266AImprove liquidityImprove uniformityLaser beam welding apparatusThick plateEngineering

The invention discloses a thick plate laser arc composite double-sided synchronous horizontal welding method and device. The horizontal welding method comprises the following steps that 1, a welding workpiece is prepared; 2, two laser arc devices are arranged on the two sides of the welding workpiece correspondingly, and the positions are adjusted; 3, welding process parameters are set, a laser arc device is started, and a base layer is welded; and 4, welding process parameters are adjusted, a laser arc device is started, and filling layer welding is performed. The method reduces the porosity of the weld joint, solves the problems of incomplete penetration of the weld joint, incomplete fusion of the side wall, weld joint cracks and the like, and ensures the quality of the weld joint and the welding stability. The horizontal welding device comprises a TIG welding gun, a first laser device, a second laser device, a GMAW welding gun and an air injection assembly.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

Method for welding by fused metal filling

InactiveCN102581497AQuality improvementPrecise Control of PenetrationWelding apparatusShielding gasWeld seam

A method for welding by fused metal filling relates to a welding method, overcomes the contradiction that deposition rate is increased while electric arc pressure is increased as well in conventional fusing pole welding, and the welding defects caused by high temperature of an electric arc. The method for welding by fused metal filling includes: firstly, fixing to-be-welded metal on a workbench, heating metal without oxidation film and made of the same material with the to-be-welded metal to fuse under the protection of protection gas, ejecting fused metal liquid to welding seams of the to-be-welded metal by a certain speed, welding by a certain welding speed, and completing welding. The method for welding by utilizing fused metal to fill has the advantages that firstly, deposition speed is increased and welding efficiency is improved evidently; secondly, the contradiction that deposition rate is increased while electric arc pressure is increased as well is avoided, the welding defects caused by high temperature of the electric arc are overcome, and joint quality is improved; and thirdly, fusing depth and width, excess deposition metal of welding seams can be accurately controlled, and adaptability is high. In addition, the method is mainly used for metal welding.

Owner:HARBIN INST OF TECH

7, 000-series alloy material for automobile bumpers, and production method thereof

The invention discloses a 7, 000-series alloy material for automobile bumpers. The 7, 000-series alloy material for the automobile bumpers is characterized in that the aluminum alloy comprises the alloy ingredients of Zn, Mg, Cu, Zr, Ti, Sn, Mn, Ag, Co, Sc, Yb, B, Cr4 and the balance aluminum and unavoidable impurities, wherein the ratio of Mg to Zn ranges from 0.17 to 0.19, the ratio of Cu to Mgranges from 0.43 to 0.53, the ratio of Cu to Ti ranges from 1.5 to 1.8, the content of one single impurity is smaller than or equal to 0.005%, the total content of the impurities is smaller than or equal to 0.1%, the average grain diameter of aluminum alloy grains ranges from 20 microns to 40 microns. When the alloy is observed through SEM and TEM, the area percentage of the strengthening phase MgZn2 ranges from 1% to 1.6% while the average size of the MgZn2 ranges from 50 nanometers to 60 nanometers, the area percentage of the strengthening phase Mg2Sn ranges from 0.3% to 0.6% while the average size of the Mg2Sn ranges from 30 nanometers to 50 nanometers, the area percentage of the strengthening phase Al6Mn ranges from 0.3% to 0.4% while the average size of the Al6Mn ranges from 20 nanometers to 30 nanometers, the area percentage of the strengthening phase Al3Ti ranges from 0.5% to 0.8% while the average size of the Al3Ti ranges from 20 nanometers to 30 nanometers, the yield strengthranges from 580 MPa to 650 Mpa, the tensile strength ranges from 670 MPa to 720 MPa, and the elongation ranges from 18% to 23%.

Owner:温州市赢创新材料技术有限公司

Method of laser welding for steel sheet and laser welding apparatus

ActiveCN102615428AReduce bad shapeReduce weld crackingWelding/soldering/cutting articlesMetal working apparatusLight beamUltimate tensile strength

Owner:NIPPON STEEL CORP +2

Wear-resisting basic flux-cored wire with excellent welding performance and preparation method

InactiveCN106736014AHigh tensile strengthImprove wear resistanceWelding/cutting media/materialsSoldering mediaAluminiumNiobium

The invention discloses a wear-resisting basic flux-cored wire with excellent welding performance, which comprises a low carbon steel skin and a flux core loaded in the low carbon steel skin. The flux core comprises components in percentage by weight: 10 to 20% of calcium oxide, 3 to 8% of graphite, 7 to 13% of alkali carbonate, 4 to 7% of nickel, 3 to 6% of manganese, 10 to 15% of rutile, 5 to 9% of aluminium magnesium alloy, 0.083 to 0.11% of niobium, 2 to 3% of ferrochromium, 3 to 5% of quartz, 0.01 to 0.03% of nitrogen, 0.2 to 2% of zirconium, and the balance of iron and unavoidable impurities. The invention further discloses a preparation method of the wear-resisting basic flux-cored wire with excellent welding performance. According to the wear-resisting basic flux-cored wire with excellent welding performance and the preparation method thereof, which are disclosed by the invention, the wear resistance of the basic flux-cored wire is ensured, the comprehensive mechanical property of weld metal is considered, meanwhile, welding process performance of the flux-cored wire is improved, arc stability is improved, splashed particles are reduced and shortened, and demands of the practical production for the wear-resisting flux-cored wire are met.

Owner:安徽飞弧焊业股份有限公司

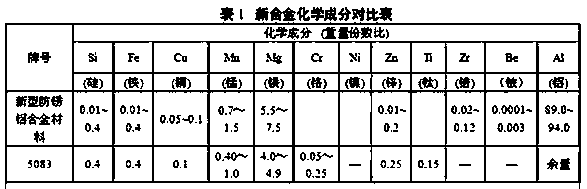

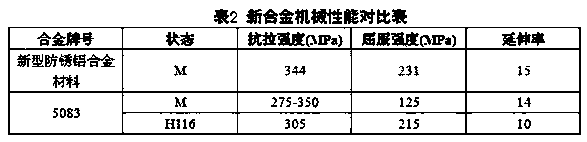

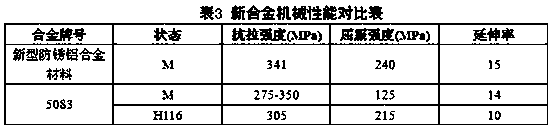

Novel antirust aluminium alloy material

The invention relates to a novel antirust aluminium alloy material. The aluminium alloy material comprises the following raw materials: Si, Fe, Cu, Mn, Mg, Zn, Zr, Be and Al. The novel antirust aluminium alloy material has the beneficial effects that the content of Zr in the novel antirust aluminium alloy material is moderate, so that the strength and plasticity of base materials and weld joints are obviously improved and the weldability is enhanced; meanwhile, Zr and Al form a ZrAl3 compound, so that a recrystallization process can be hindered and recrystallized grains can be refined; and by adding a small quantity of Zn to the novel antirust aluminium alloy material, the strength of the base materials and the weld joints can be effectively improved via the dispersion strengthening effects of the precipitated MgZn2 phase and Al2Zn3Mg3 phase, and the corrosion resistance of the base materials and the weld joints is optimal. Therefore, the novel aluminium alloy material has high mechanical strength and strong corrosion resistance and weldability, and solves the problem of gaps in the materials of large-scale all aluminium alloy high-speed ships (hovercrafts) in China.

Owner:BEIJING ALUMIP DEVING

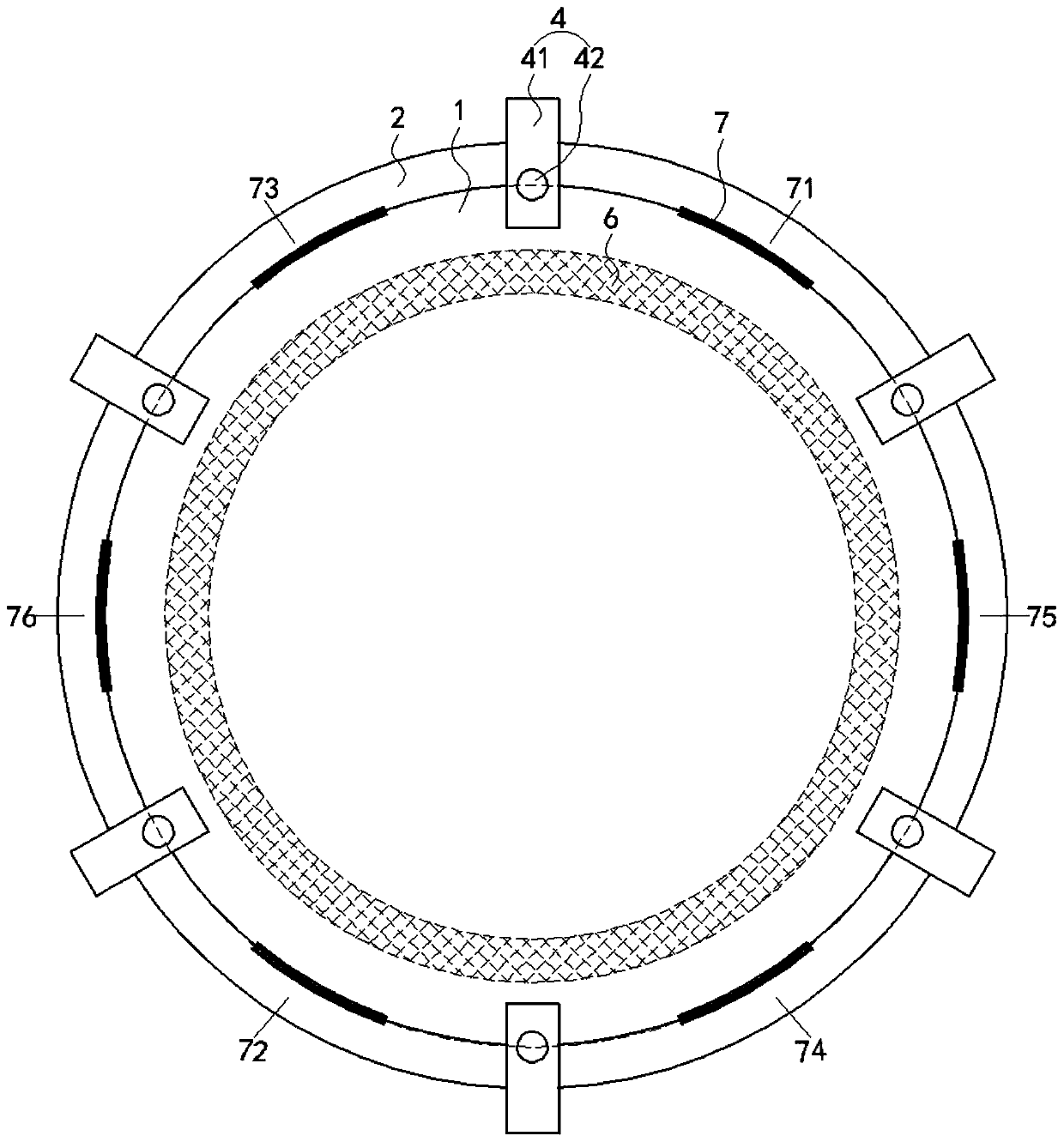

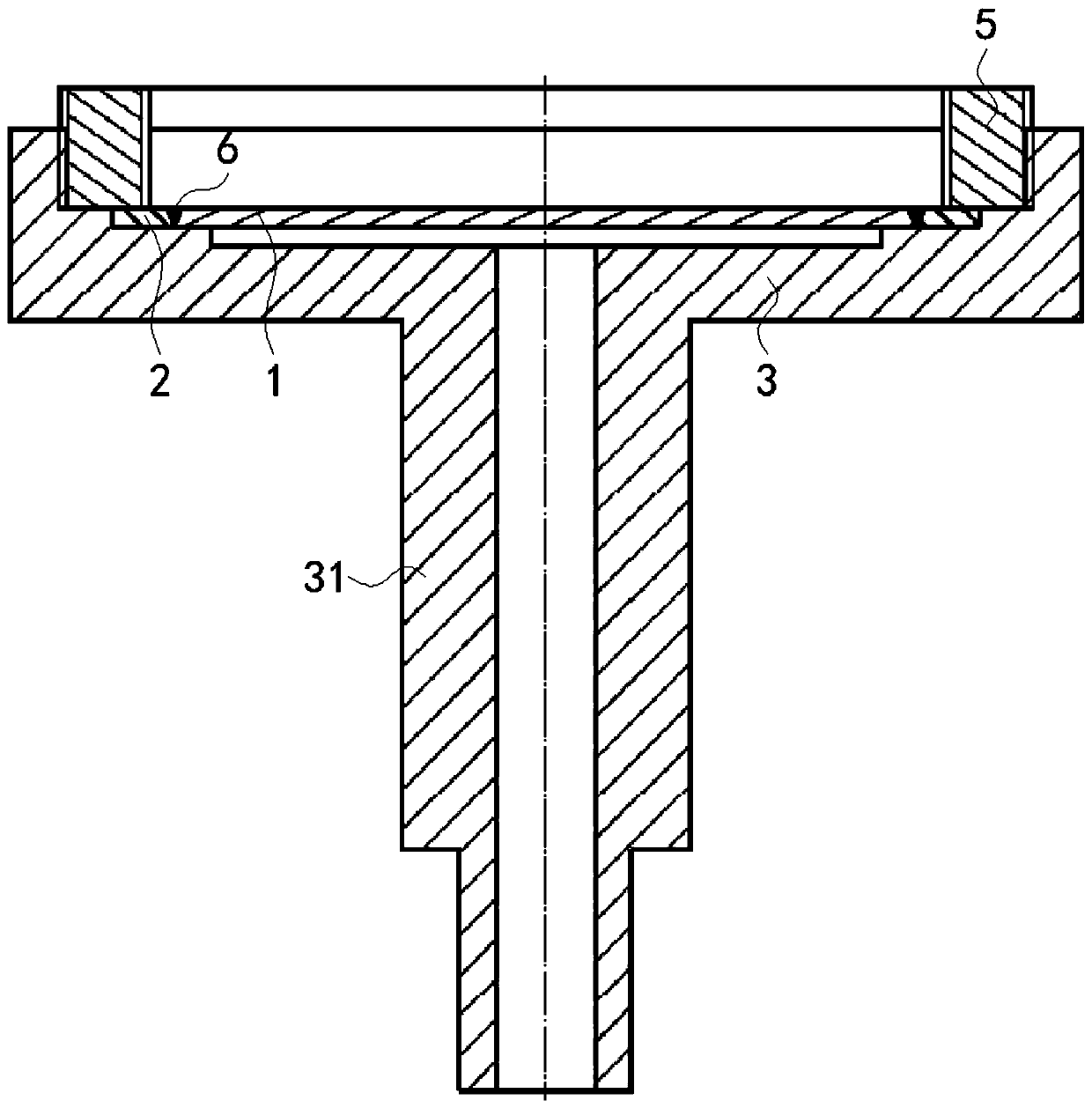

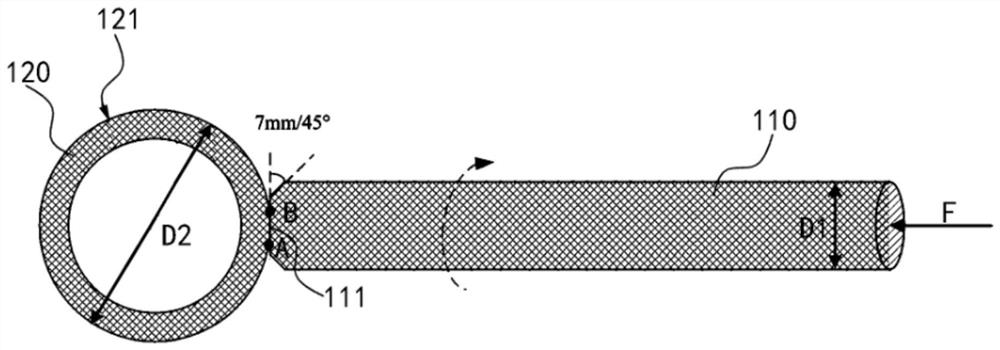

Method for welding large-size thin-walled beryllium piece and aluminum alloy ring

ActiveCN111215741AAvoid welding deformationNo filler requiredElectron beam welding apparatusWelding deformationWelding process

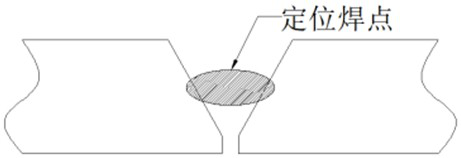

The invention discloses a method for welding a large-size thin-walled beryllium piece and an aluminum alloy ring, and belongs to the technical field of welding methods for beryllium pieces and aluminum alloy rings. The method for welding the large-size thin-walled beryllium piece and the aluminum alloy ring includes the following steps that positioned welding clamping is carried out, the berylliumpiece is nested in the aluminum alloy ring in a fit manner, and the beryllium piece and the aluminum alloy ring are clamped on a rotary table by positioning pincers; positioned welding is carried out, symmetrical positioned welding is conducted on the beryllium piece and the aluminum alloy ring by vacuum electron beam welding to form a positioned welding assembly; full weld clamping is carried out, the positioning pincers are disassembled, and the aluminum alloy ring of the positioned welding assembly is clamped on the rotary table by a positioning ring; and full welding is carried out, fullwelding is conducted on the beryllium piece and the aluminum alloy ring by vacuum electron beam welding to form a full welding assembly. Welding deformation of the beryllium piece and the aluminum alloy ring in the welding process can be restrained, welding cracks are not prone to occurring, and the obtained welded joint can also meet use requirements of high environment temperatures and other harsh environments.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

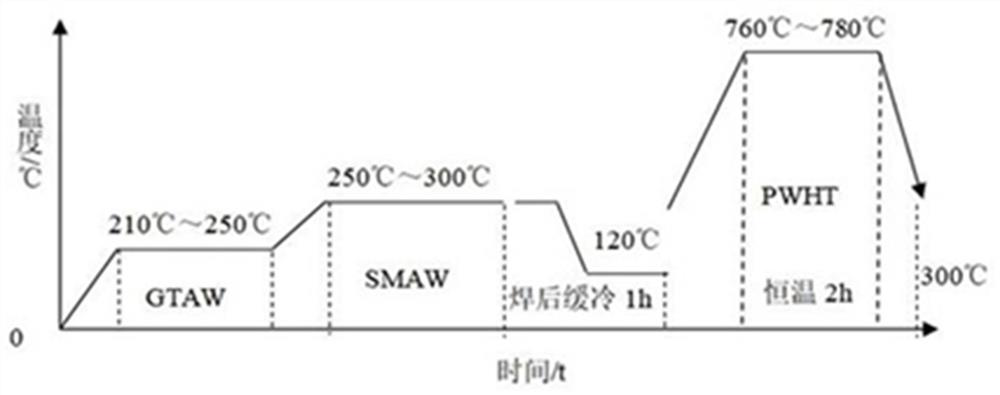

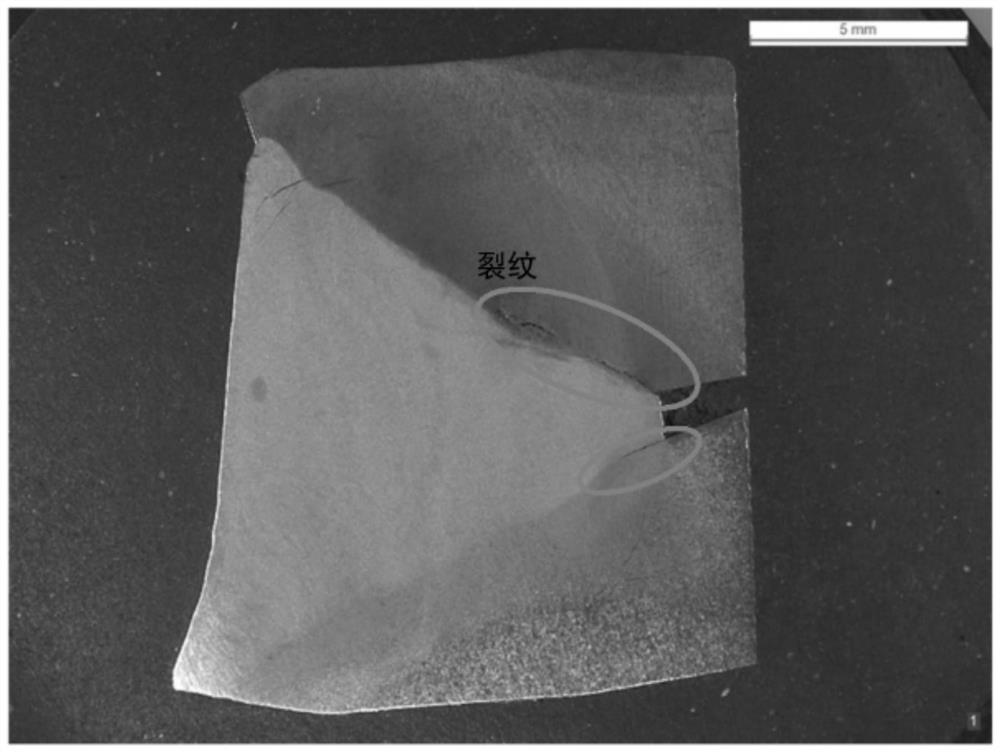

Welding and repairing method of heat-resisting steel casting

InactiveCN108856945AReduce carbon increase on siteImprove welding pass rateWelding/cutting auxillary devicesAuxillary welding devicesMartensiteSteel casting

The invention belongs to the technical field of heat-resisting steel welding, particularly relates to a repairing method of a high-chromium martensite heat-resisting steel casting, and provides a welding and repairing method of a novel heat-resisting steel casting. The method comprises the main steps of defect treatment before welding, welding preheating, welding, heating after welding, and heat treatment after welding. By the adoption of the welding and repairing method, generation of weld cracks is reduced, the yield of welding and repairing is increased, the number of times of welding is reduced, and the repairing cost is reduced substantially.

Owner:KOCEL STEEL

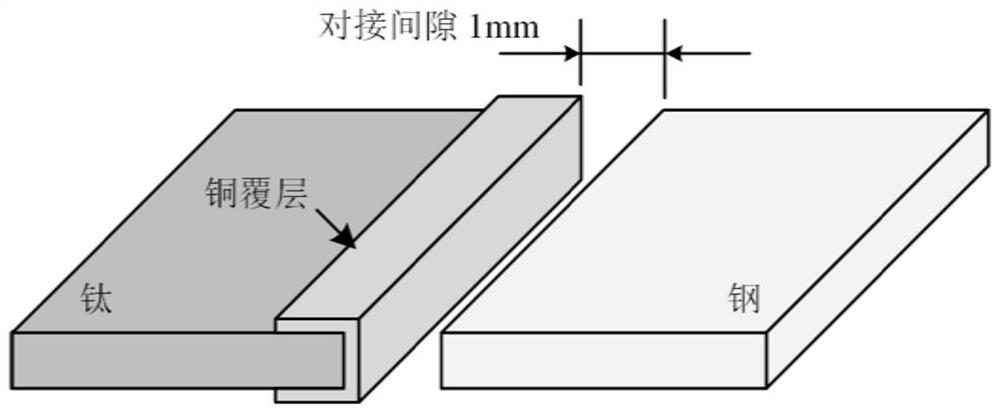

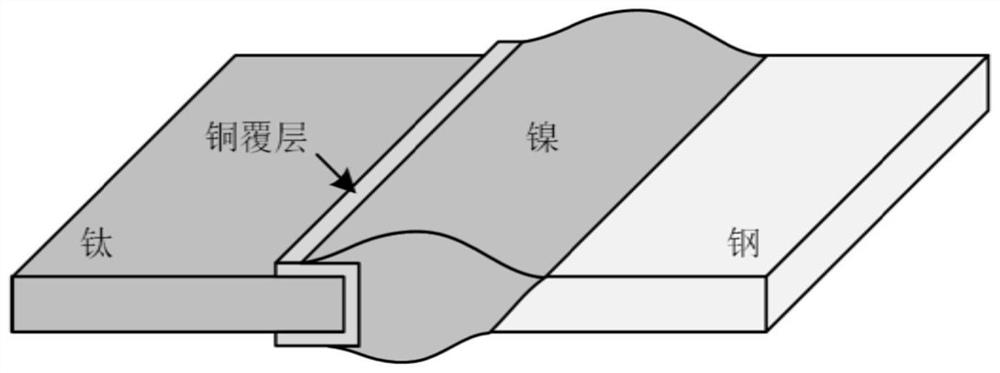

Titanium alloy and steel dissimilar metal tungsten electrode argon arc fusion welding process based on copper-nickel composite middle layer

InactiveCN111940874AReduce stressSmall deformation after weldingArc welding apparatusWelding/soldering/cutting articlesThermal dilatationTitanium alloy

The invention provides a titanium alloy and steel dissimilar metal tungsten electrode argon arc fusion welding process based on a copper-nickel composite middle layer, and belongs to the field of dissimilar metal composite structure manufacturing. The welding process can effectively solve the problems that a titanium / steel dissimilar metal fusion welding joint is low in strength, prone to cracking, narrow in process window and the like due to brittle phase generation and thermal expansion coefficient mismatch. A titanium alloy, a copper coating, a nickel-based welding wire and stainless steelare sequentially arranged on a middle layer of a joint. By adopting the copper-nickel composite middle layer, the generation of brittle intermetallic compounds in the titanium / steel fusion welding joint can be effectively regulated and controlled, the welding stress of the titanium / steel fusion welding joint is reduced, and the generation of welding cracks is reduced. By the adoption of the welding process, the high-quality titanium / steel dissimilar metal fusion welding joint which is high in strength, attractive in appearance and free of cracks and has certain ductility and toughness can be obtained.

Owner:DALIAN UNIV OF TECH

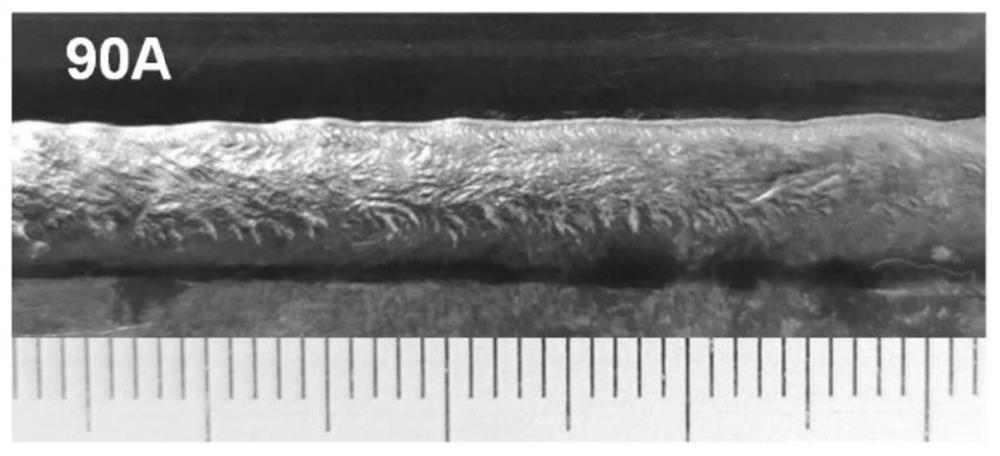

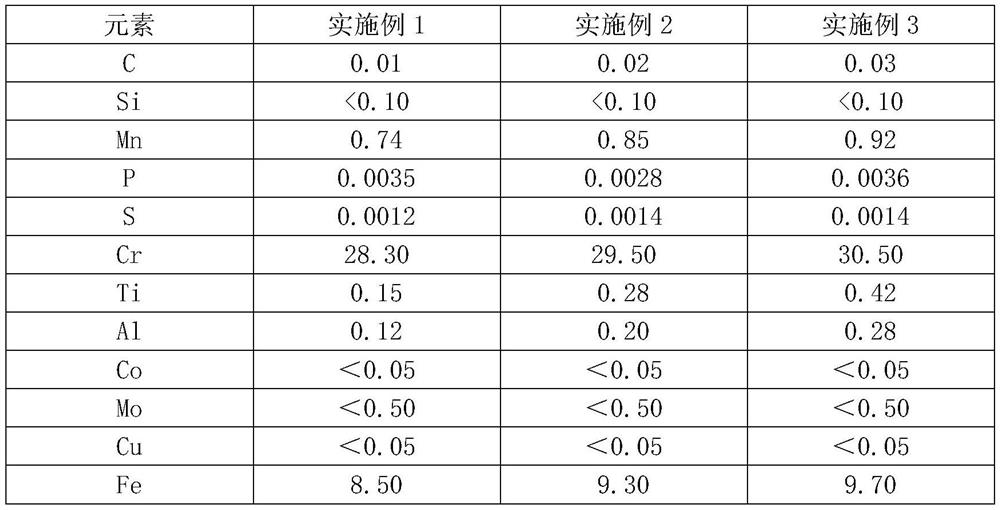

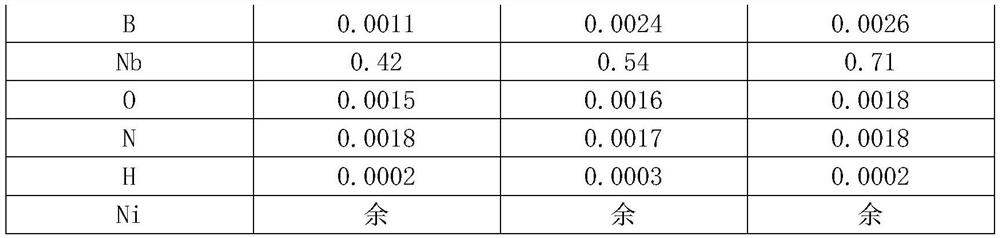

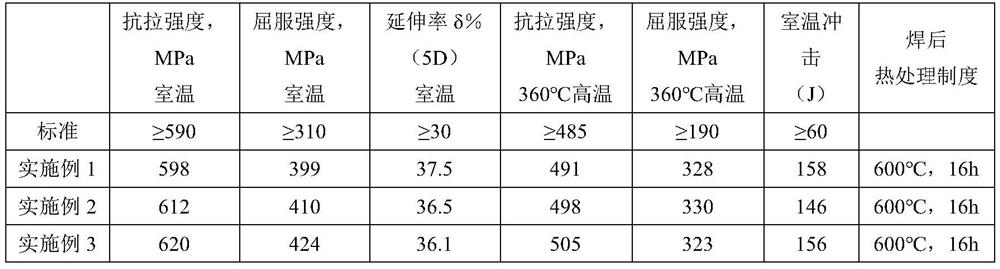

Nickel-based alloy welding wire for welding dissimilar steel of nuclear island main equipment and preparation and use method

ActiveCN111889916AHigh tensile strengthImprove toughnessWelding/cutting media/materialsSoldering mediaNuclear powerAlloy

The invention provides a nickel-based alloy welding wire for welding dissimilar steel of nuclear island main equipment and a preparation and use method, and belongs to the field of welding materials.The nickel-based high-temperature alloy welding wire comprises the following components of, in percentage by weight, C less than or equal to 0.04%, 28.00%-31.50% of Cr, Mo less than or equal to 0.50%,Co less than or equal to 0.05%, 0.10%-0.30% of Al, 0.10%-0.50% of Ti, 0.0010%-0.0030% of B, 0.40%-0.80% of Nb, N less than or equal to 0.002%, Si less than or equal to 0.10%, 0.50%-1.00% of Mn, P less than or equal to 0.0050%, S less than or equal to 0.0020%, Cu less than or equal to 0.05%, 8.00%-10.00% of Fe, O less than or equal to 0.002%, H less than or equal to 0.001%, and the balance Ni andinevitable impurity elements. According to the nickel-based alloy welding wire for welding the dissimilar steel of the nuclear island main equipment and the preparation and use method, the componentsof the materials are reasonably configured, the preparation of the welding wire alloy can meet the development requirement of a nuclear power station, the material performance of nuclear power stationequipment can be improved, the room-temperature tensile strength of a deposited metal is larger than or equal to 580 MPa, the 360-DEG C high-temperature tensile strength is larger than or equal to 490 MPa, and the room-temperature impact (work) is larger than or equal to 150 J.

Owner:UNIV OF SCI & TECH BEIJING

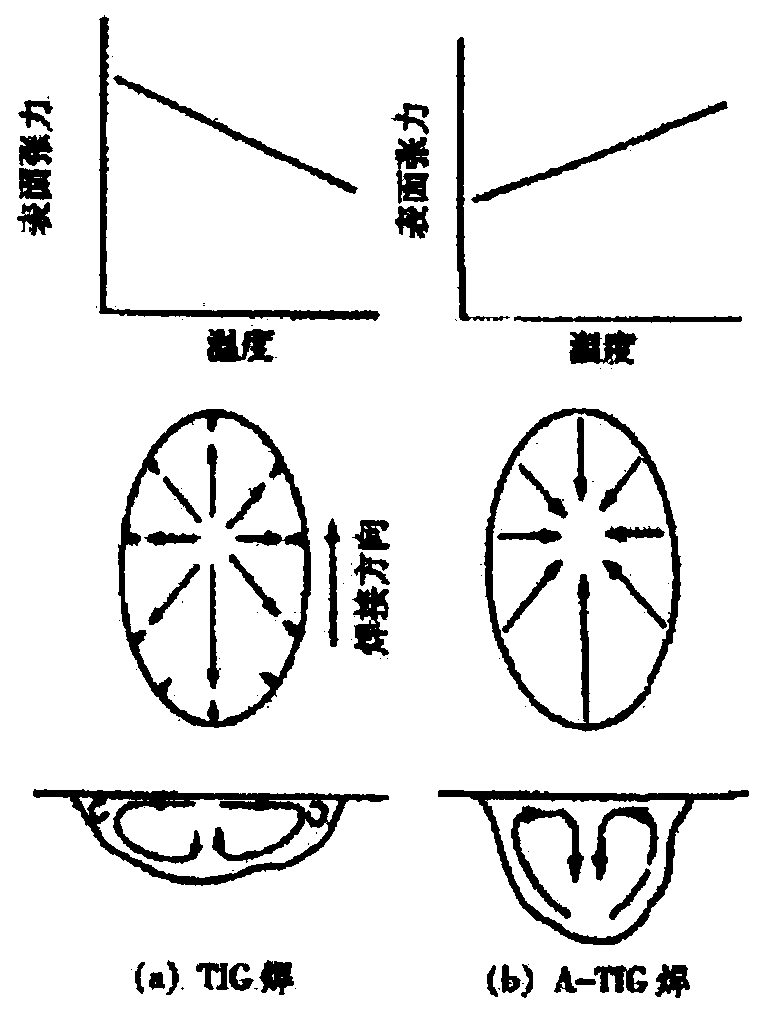

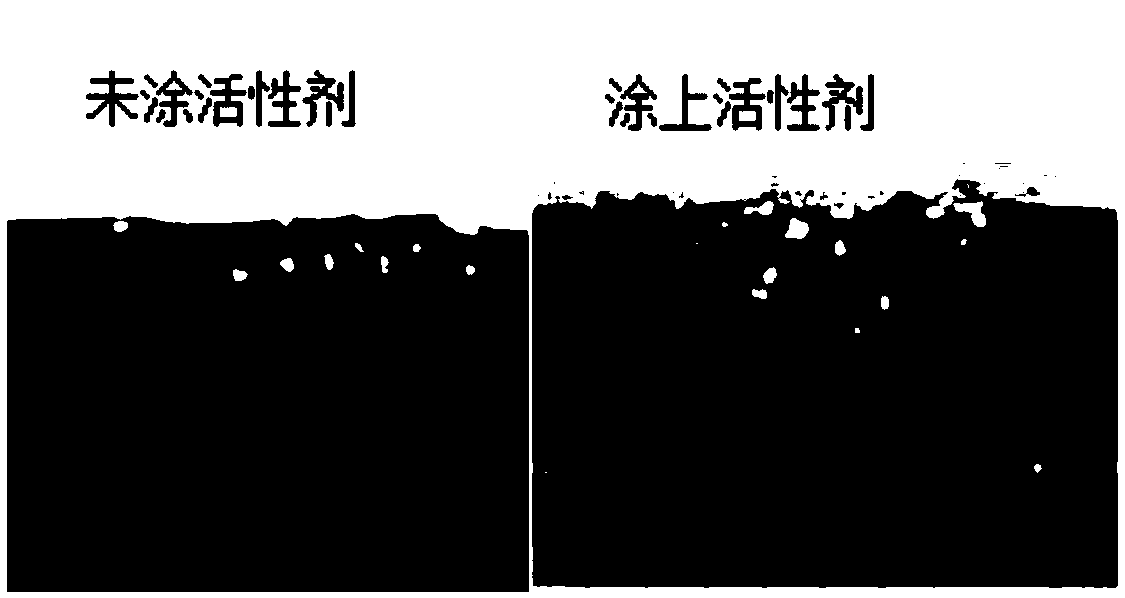

Silicon steel sheet welding active agent and application method thereof

InactiveCN109128581AIncrease weld penetrationHigh aspect ratioArc welding apparatusWelding/cutting media/materialsWeld seamActive agent

The invention discloses a silicon steel sheet welding active agent and an application method thereof. The silicon steel sheet welding active agent and the application method thereof are suitable for welding of soft magnetic material silicon steel sheets. The silicon steel sheet welding active agent is characterized in that the active agent is composed of NaF, Fe2O3, MnO2, SiO2 and TiO2; the mass content of NaF ranges from 5% to 10%; the mass content of Fe2O3 ranges from 30% to 40%; the mass content of MnO2 ranges from 20% to 30%; and the balance is SiO2 and TiO2. The application method of theactive agent comprises the steps that active agent burdening is carried out according to the weight ratio, after being fully and evenly mixed, raw materials are mixed with an organic solution, and a mixture is stirred into paste; a welding sample is carefully ground through a stainless steel wire brush till bright metal is exposed; and the surface of a welding workpiece is coated with the preparedpasty mixture so as to cover the original metal luster. By means of the silicon steel sheet welding active agent, welding penetration of the silicon steel sheet can be increased, a welding seam is attractive and level, and the cracking problem during silicon steel sheet welding can be effectively reduced.

Owner:江阴市高拓精密模具有限公司

Non-preheating welding method of 750MPa-grade high-strength steel medium-thickness plate for hydraulic support

ActiveCN113275710AMitigate the effects of weldingEasy to operateWelding accessoriesHydraulic pressureManufacturing engineering

The invention provides a non-preheating welding method of a 750MPa-grade high-strength steel medium-thickness plate for a hydraulic support. The non-preheating welding method comprises the following steps: assembling parts into a hydraulic support structural part assembly; carrying out manual tack welding on all welding seams of the assembled hydraulic support structural part assembly; carrying out manual overall backing welding on the hydraulic support structural part assembly subjected to manual tack welding; carrying out overall backing welding on the hydraulic support structural part assembly subjected to manual overall backing welding through a welding robot; and carrying out filling welding and cosmetic welding on the hydraulic support structural part assembly subjected to overall backing welding through the welding robot one welding bead after the other through the welding robot. The non-preheating welding method of the 750MPa-grade high-strength steel medium-thickness plate for the pressing support has the advantages that the design is scientific, the preheating step is not needed, the welding quality can be guaranteed, and application and popularization are easy.

Owner:ZHENGZHOU COAL MINING MACHINERY GRP

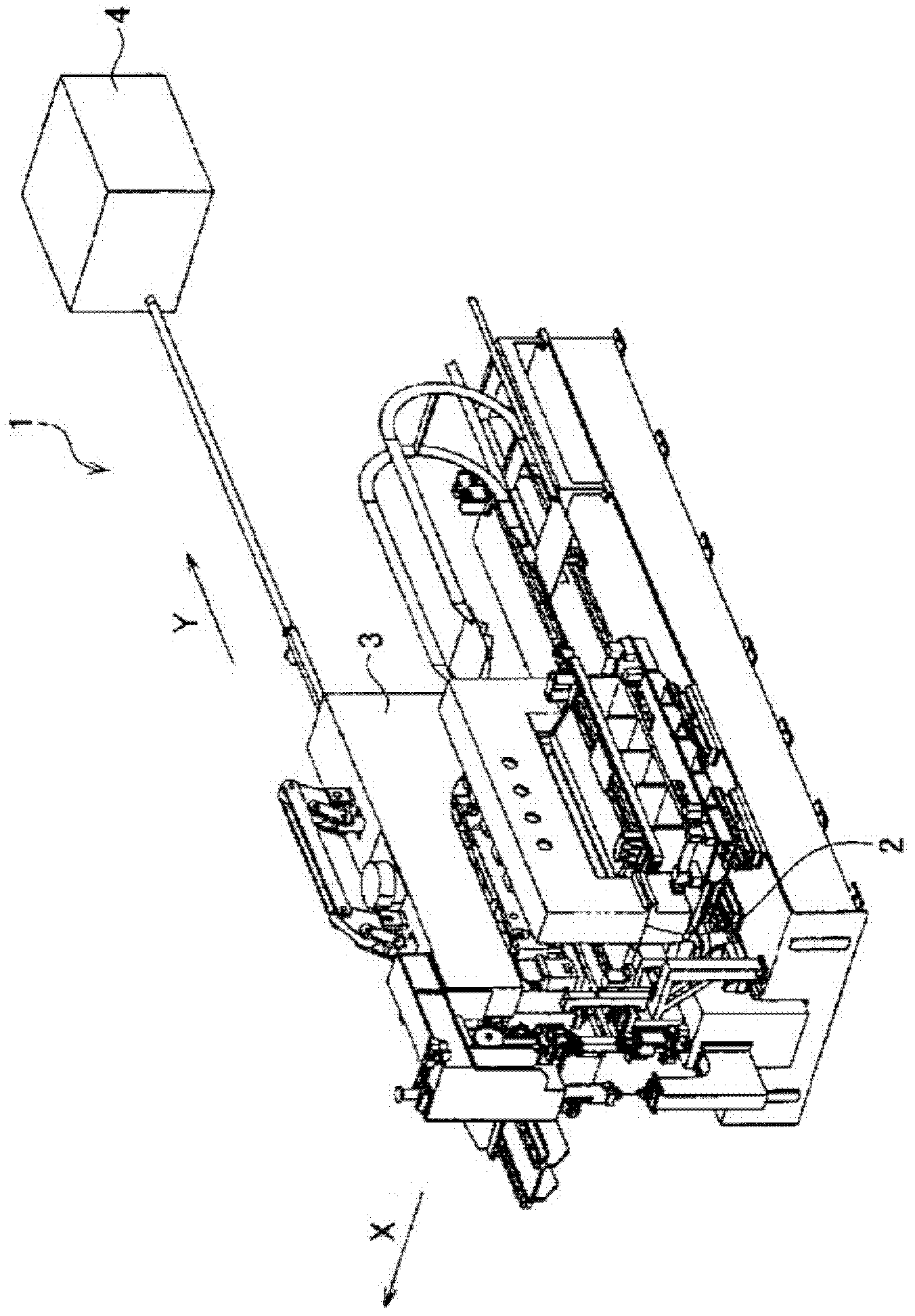

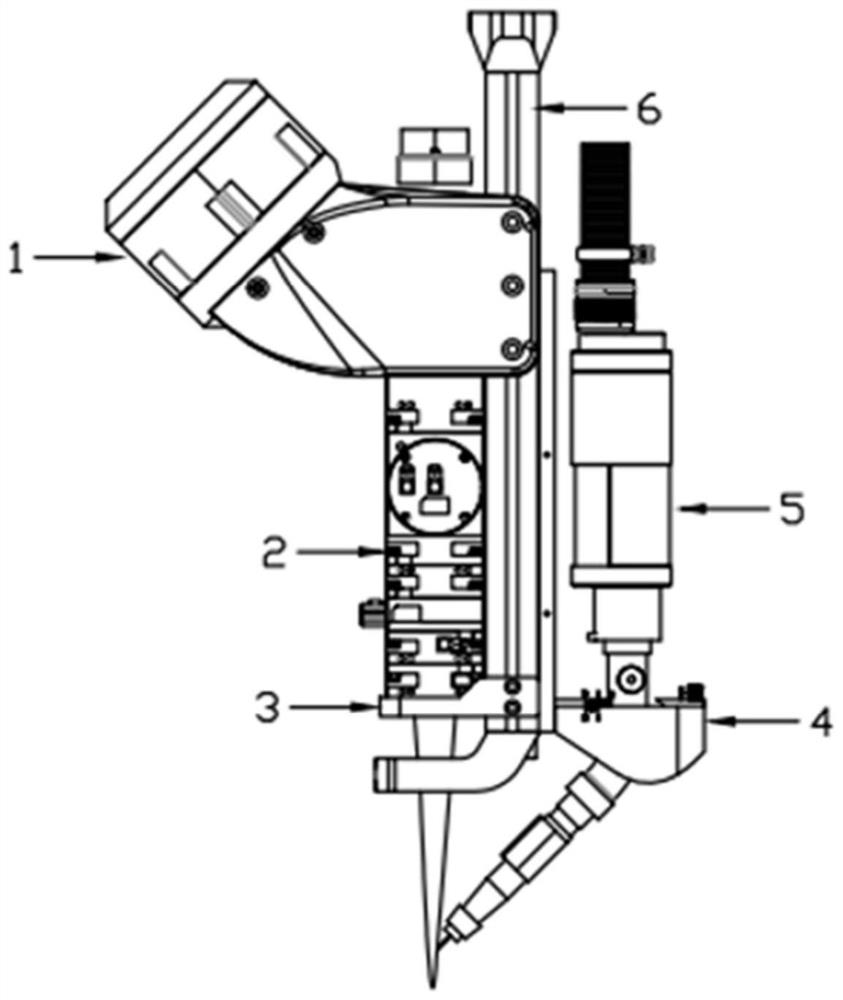

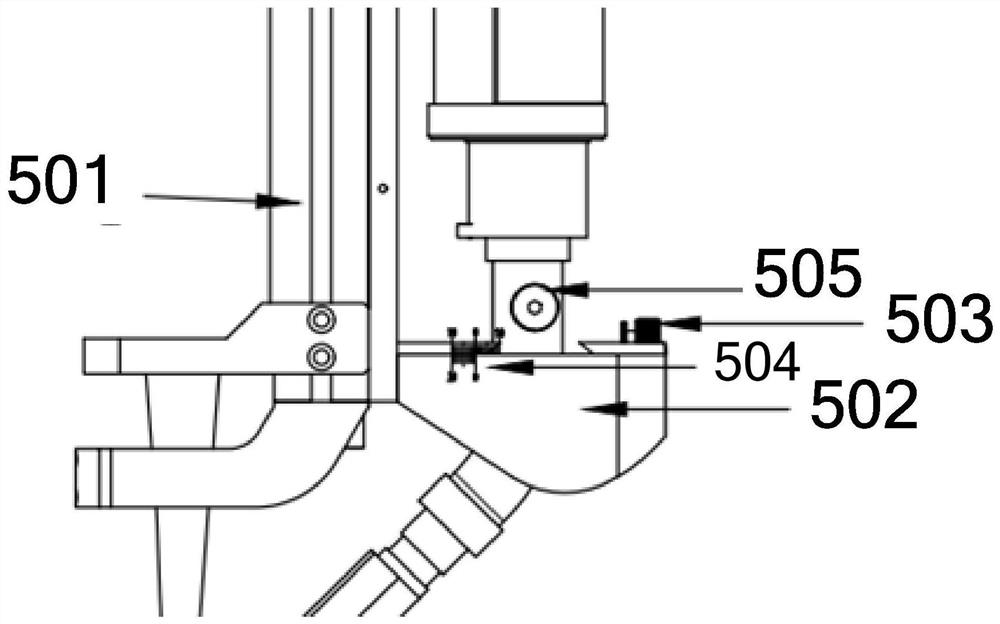

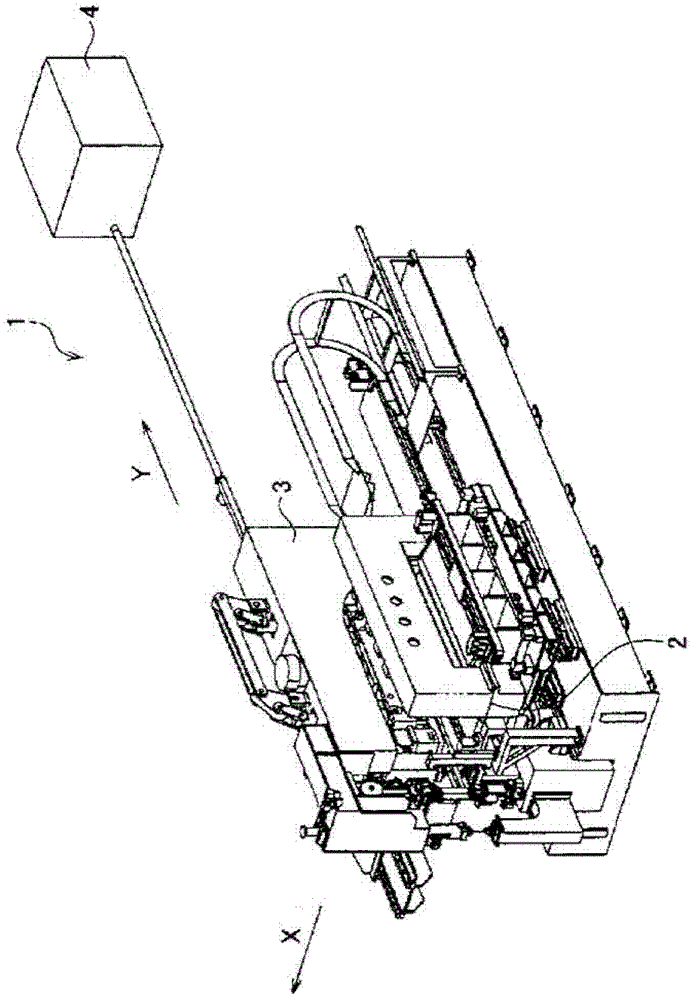

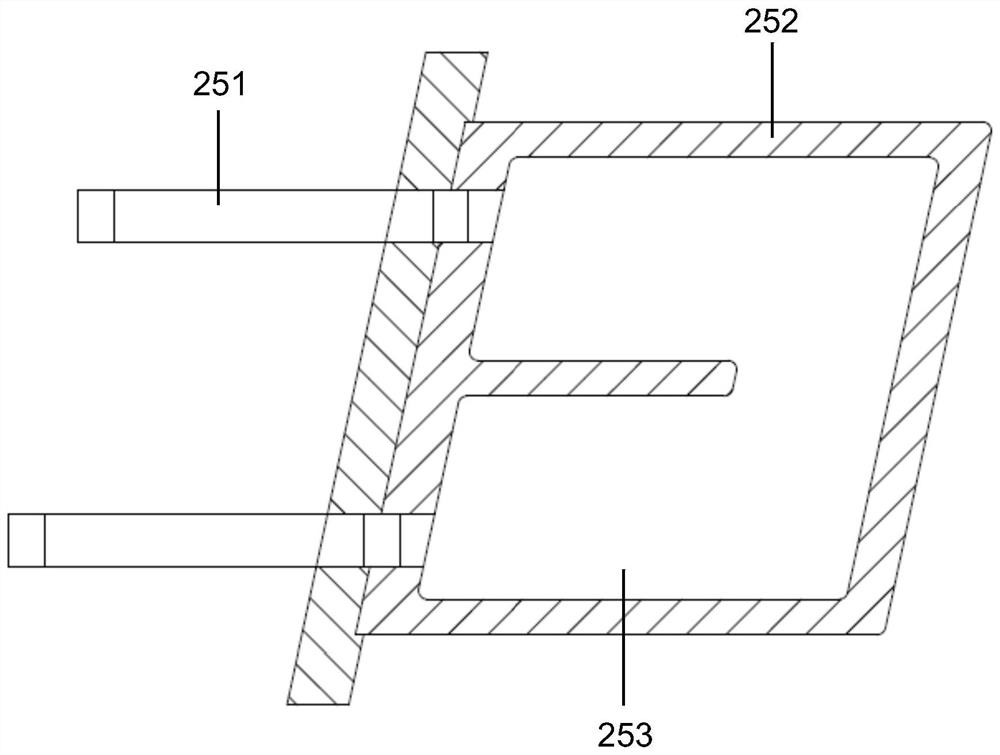

Laser-arc hybrid welding system

PendingCN114029621AConvenient process welding adjustmentReduce weld crackingLaser beam welding apparatusControl systemLaser light

The invention provides a laser-arc hybrid welding system. A welding device comprises a main body framework, wherein the main body framework is provided with a laser focusing device, a first adjusting mechanism, a welding gun, a second adjusting mechanism and a movement mechanism connecting assembly; the laser focusing device is connected to the first adjusting mechanism, and the first adjusting mechanism is connected to the main body framework; the movement mechanism connecting assembly is connected to the main body framework; the welding gun is connected to the second adjusting mechanism, and the second adjusting mechanism is connected to the main body framework; a laser light-emitting system is connected with the laser focusing device through an optical fiber; and the control system is connected with the laser light-emitting system, the laser focusing device, the first adjusting mechanism, the welding gun and the second adjusting mechanism. The system is favorable for reducing welding cracks and improving the mechanical property of welding seams, and is suitable for various welding processes with high requirements.

Owner:上海杭和智能科技有限公司

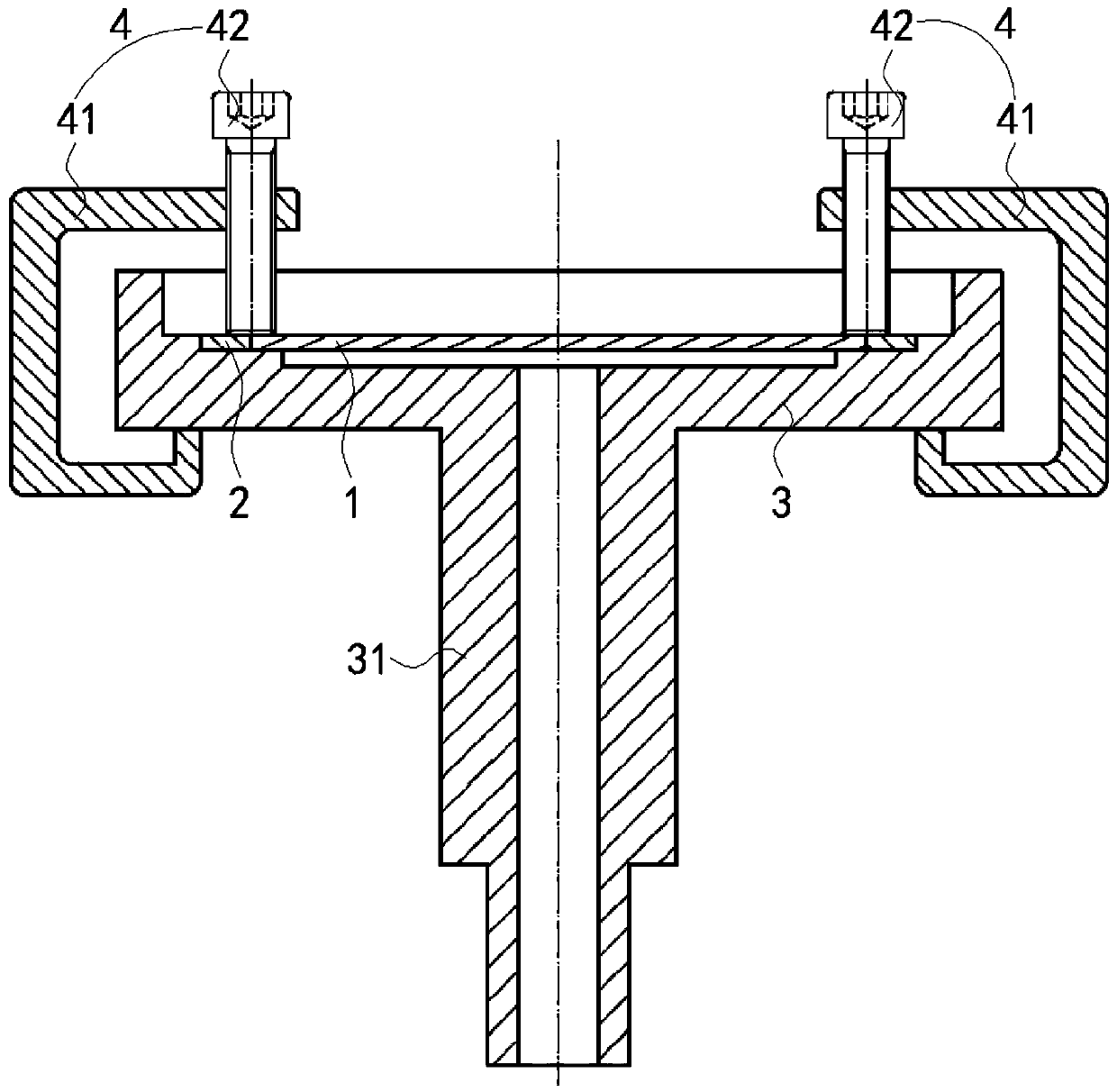

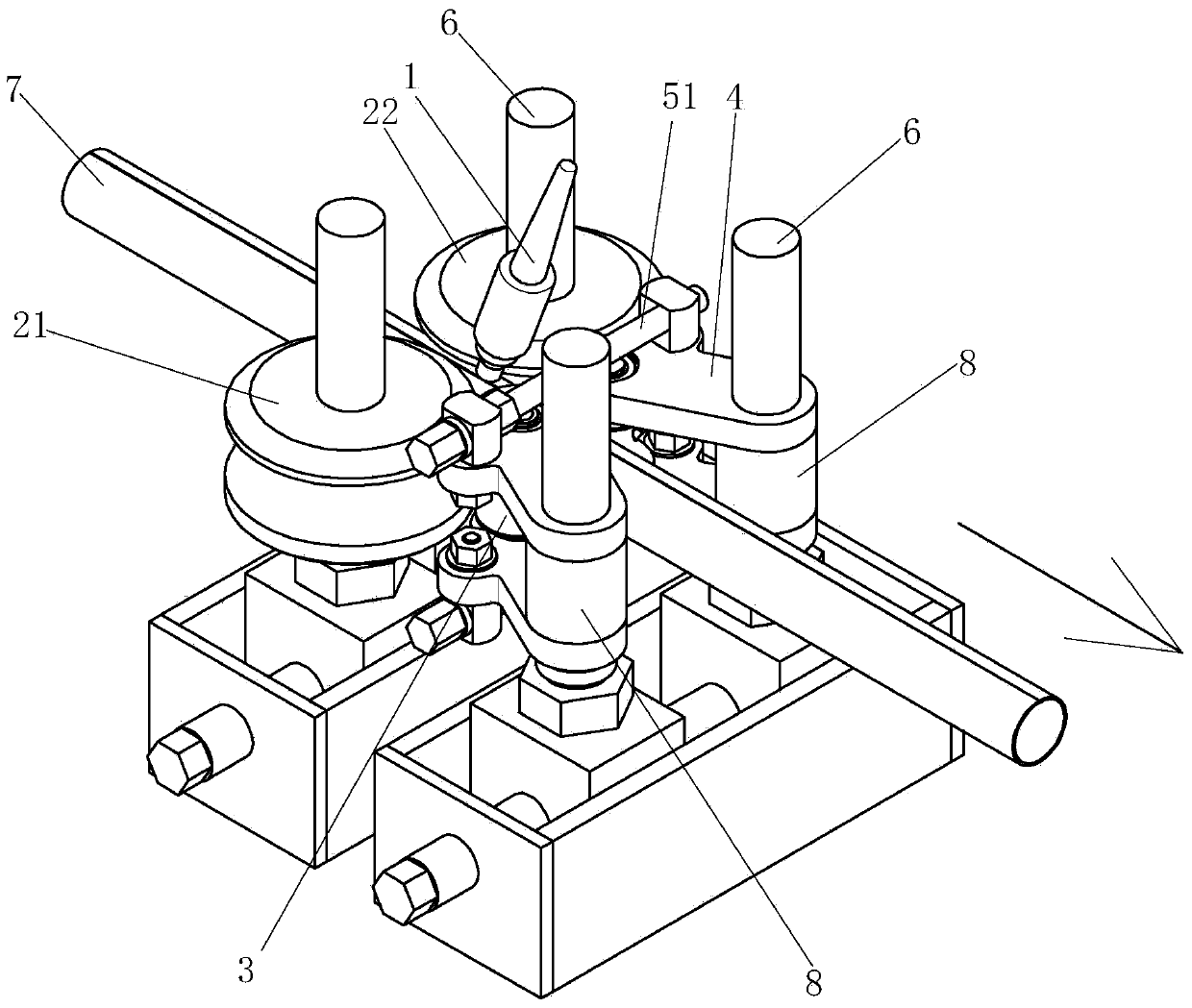

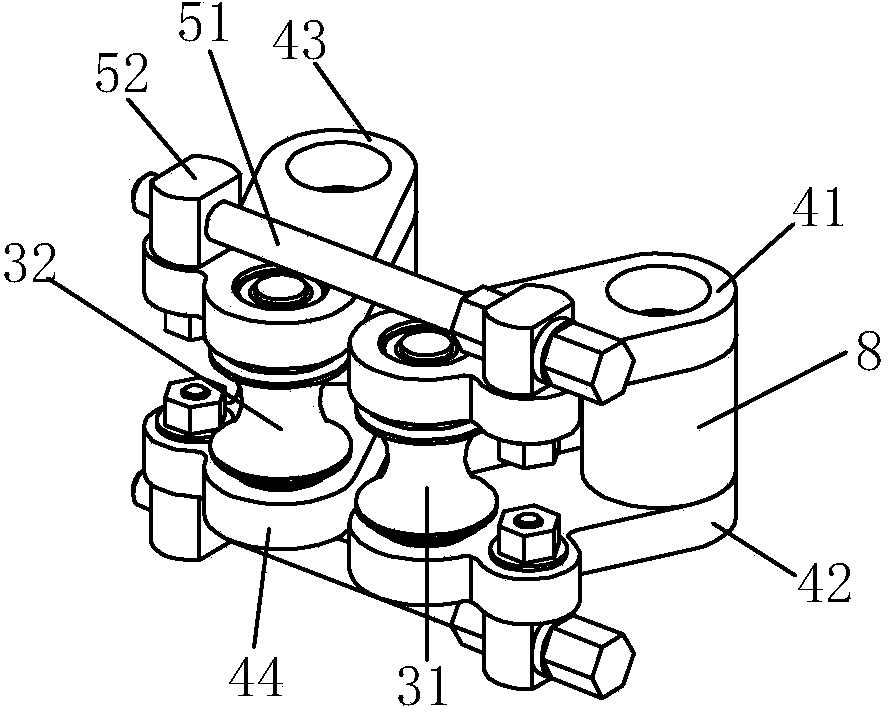

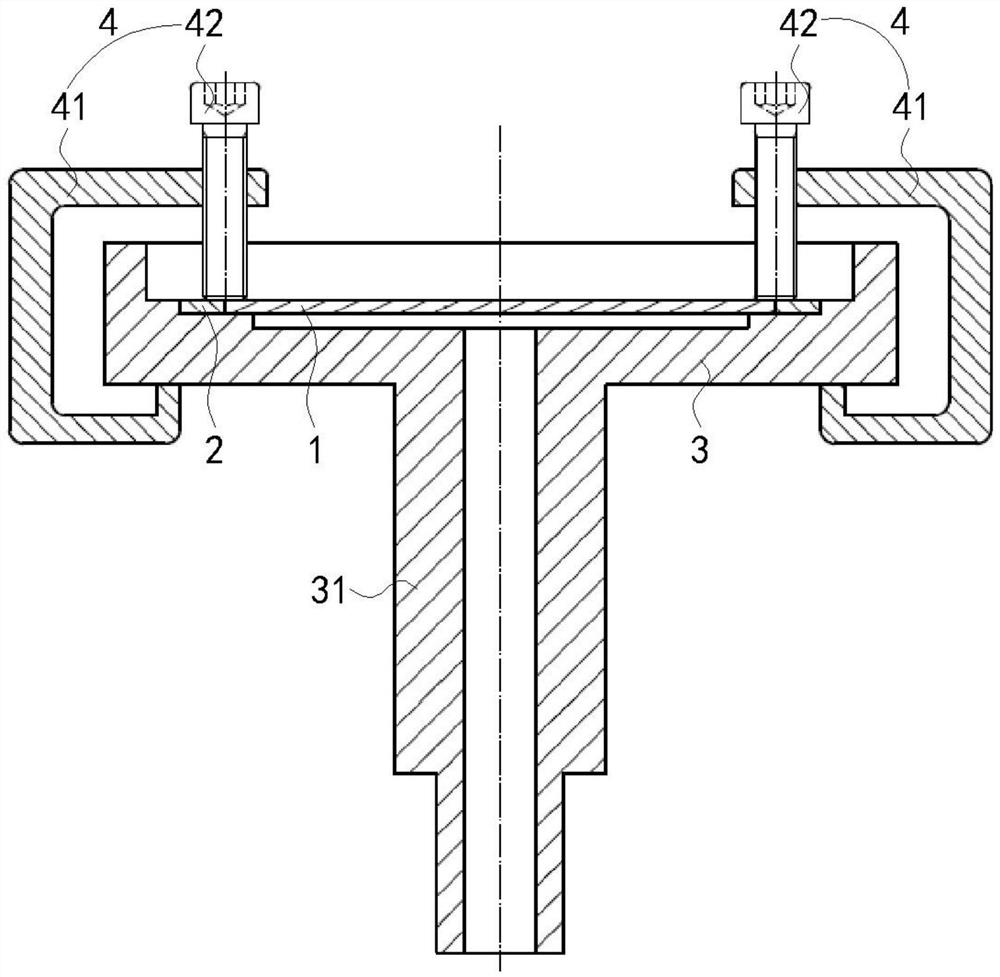

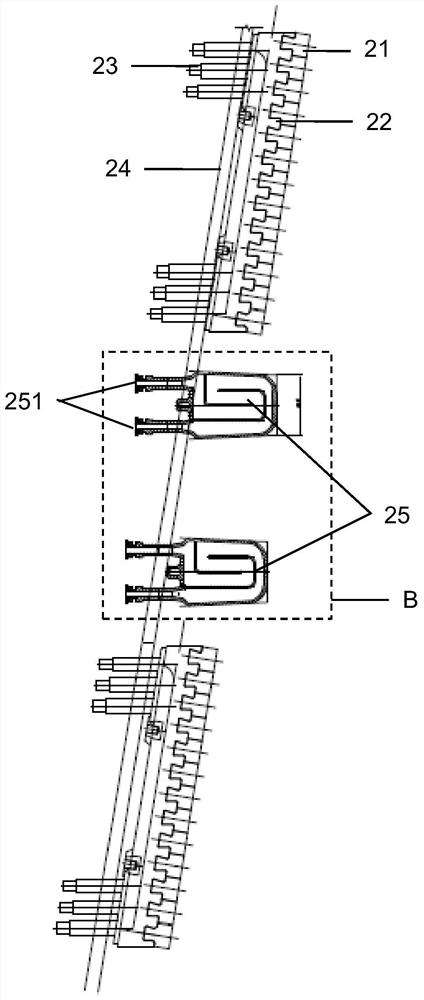

Welding pipe adjustable vertical roll tool

ActiveCN104625367AImprove the mechanical properties of the weldReduce weld crackingWelding accessoriesPipe weldingManufacturing engineering

The invention relates to a welding pipe adjustable vertical roll tool comprising a welding torch, large vertical rolls, small vertical rolls, cantilevers and pull rods. The small vertical rolls include the first small vertical roll and the second small vertical roll, the cantilevers include the first cantilever, the second cantilever, the third cantilever and the fourth cantilever, the pull rods include the first pull rod and the second pull rod, two ends of the first small vertical roll are respectively mounted on the first cantilever and the second cantilever, two ends of the second small vertical rod are respectively mounted on the third cantilever and the fourth cantilever, two ends of the first pull rod are respectively mounted on the first cantilever and the third cantilever through screw pairs, two ends of the second pull rod are respectively mounted on the second cantilever and the fourth cantilever through screw pairs, a first roll shaft is arranged on the first cantilever and the second cantilever, a second roll shaft is arranged on the third cantilever and the fourth cantilever, and the first roll shaft and the second roll shaft are mounted on a pipe welding machine through the screw pairs respectively. By the arrangement, mechanical property of welding lines is improved, weld failure caused by subsequent bend machining or flaring machining is reduced, and rejection rate of products is decreased.

Owner:LIUZHOU HENGZHUO AUTO PARTS

Welding method for panel assembly of low-frequency tester

InactiveCN106270961AEliminate internal stressEliminate work hardeningWelding/cutting auxillary devicesArc welding apparatusPower flowGasoline

The invention provides a welding method for a panel assembly of a low-frequency tester. The welding method comprises the following steps of 1, cleaning, wherein the panel assembly is cleaned with gasoline and then naturally aired; 2, thermal treatment, wherein the panel assembly is put into an oven at the temperature of 350-370 DEG C, heat preservation is carried out for 3 h, and the oven is cooled to the room temperature; 3, acid pickling, wherein the panel assembly is subjected to acid pickling with a spray acid pickling method; 4, welding, wherein the panel assembly is welded with the welding current being 80-90 A; 5, mark milling, wherein welding marks at the welding part of the panel assembly are primarily treated in a milling mode; 6, mark trimming and filing, wherein the welding marks at the welding part of the panel assembly are finely treated in a filing mode. According to the welding method, by improving the process, the internal stress generated in the assembly machining process can be effectively eliminated, machining hardening can be eliminated, hardness can be reduced, and plasticity can be improved, so that welding deformation is effectively controlled, the probability of welding cracks is reduced, and the welding percent of pass is improved and reaches 90% or above.

Owner:GUIZHOU AEROSPACE ELECTRONICS TECH CO LTD

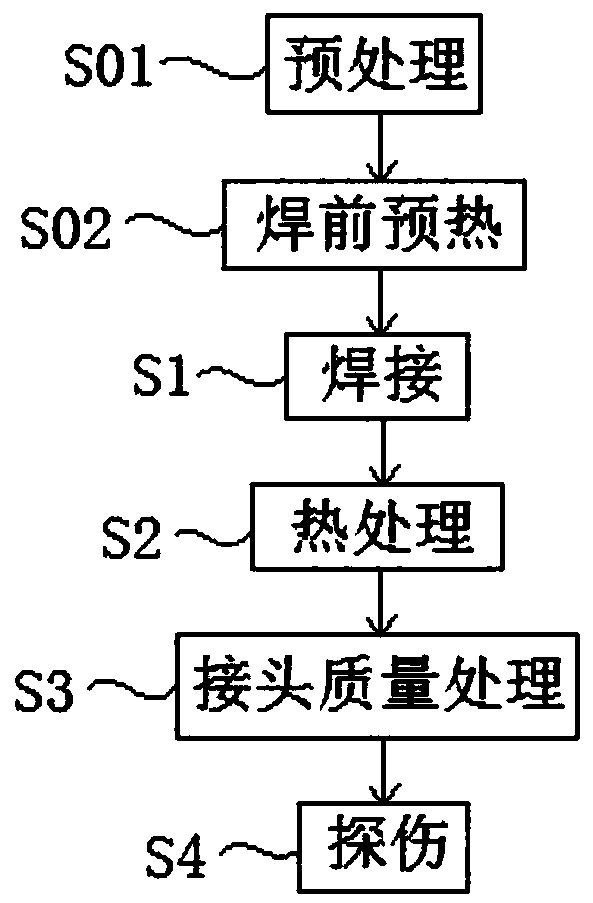

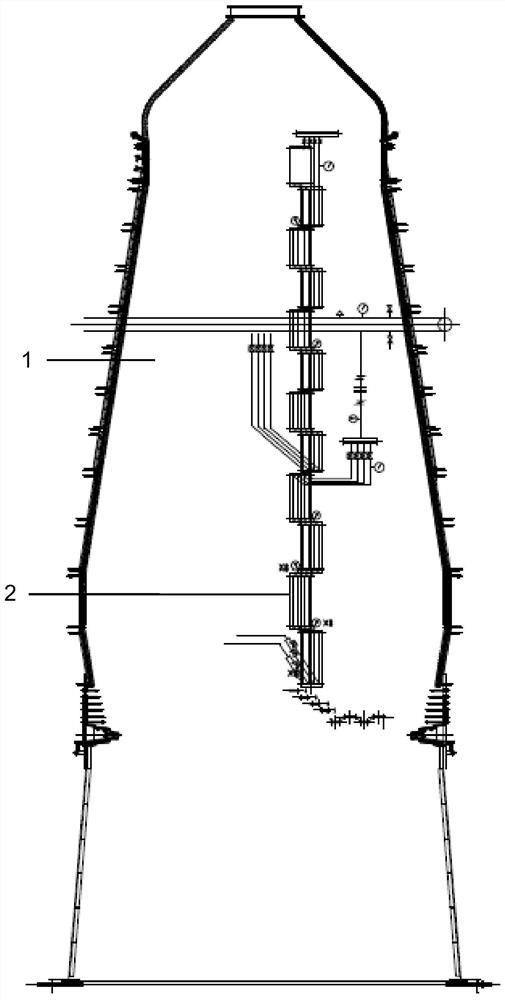

Steam feeding insert pipe and cylinder body butting and fixing process for steam turbine

InactiveCN108994472AImprove welding reliabilityReduce weld crackingWelding apparatusEngineeringWelding defect

The invention provides a steam feeding insert pipe and cylinder body butting and fixing process for a steam turbine. The process comprises the following steps of: welding, namely selecting an E6015-B3(R407) welding bar as a welding material for filling a welding seam between a steam feeding insert pipe (1Cr9Mo1VNbN) and a cylinder body (ZG15Cr2Mo1) and carrying out welding; carrying out thermal treatment, namely carrying out after-welding thermal treatment on the welding seam which is formed in welding; processing the quality of a joint; and removing the filling welding material which is exposed out of the joint. Thus, by accurately selecting the welding material and strictly controlling the technological parameters, the occurrence probability of cracking of the welding seam and welding defects is reduced, and the welding reliability of a butted position of the steam feeding insert pipe and the cylinder body is improved.

Owner:陕煤电力信阳有限公司

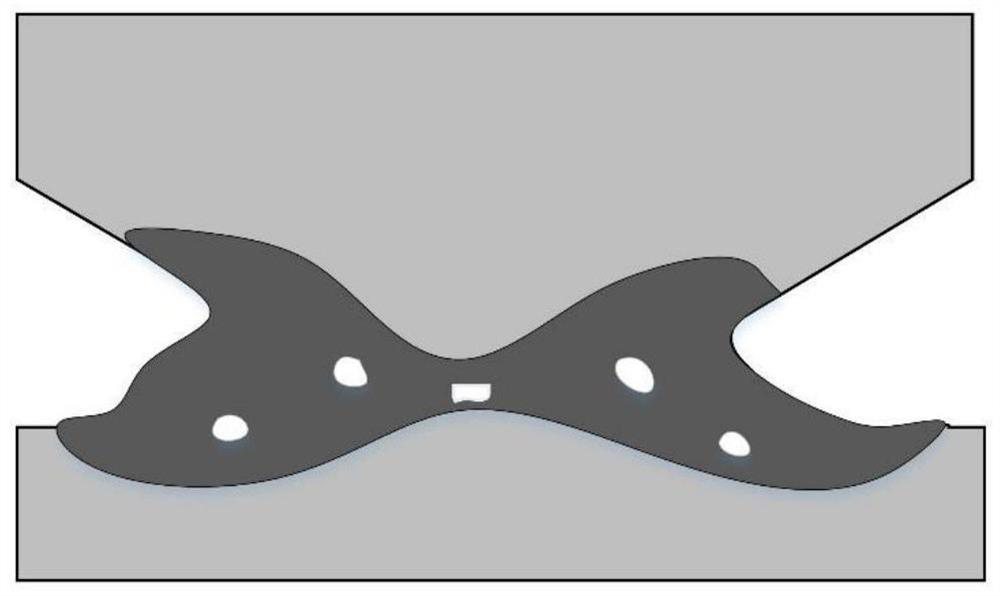

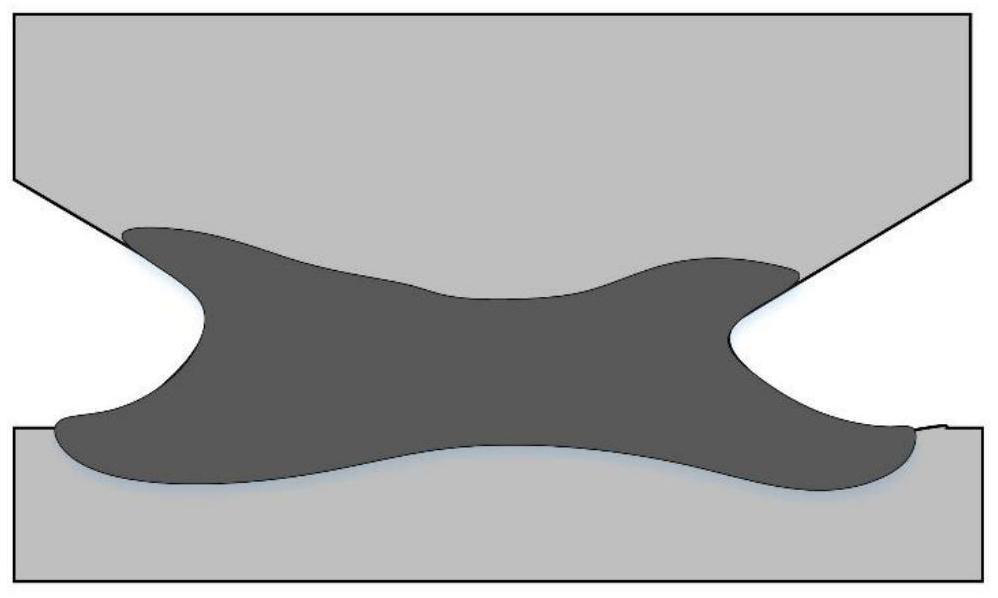

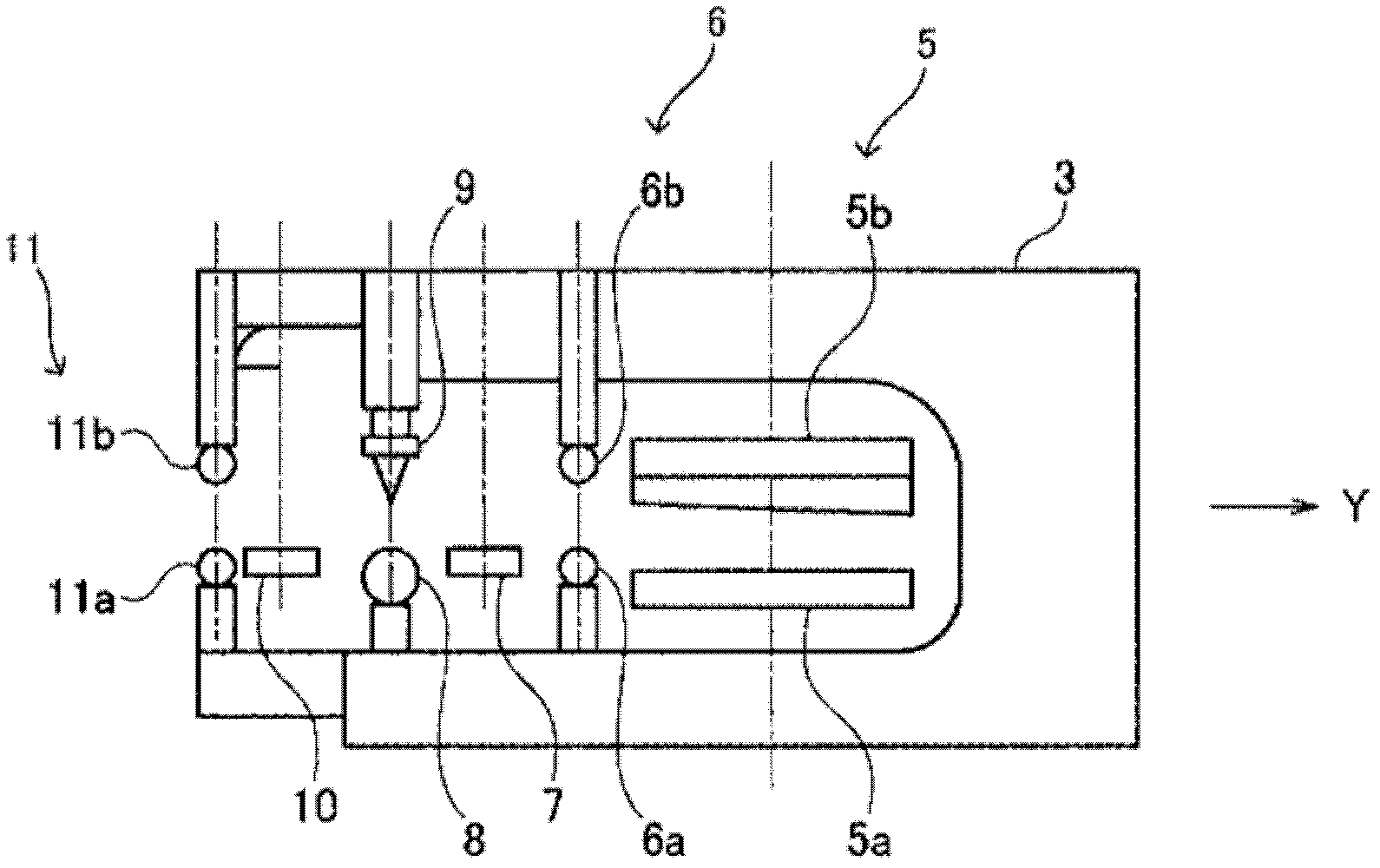

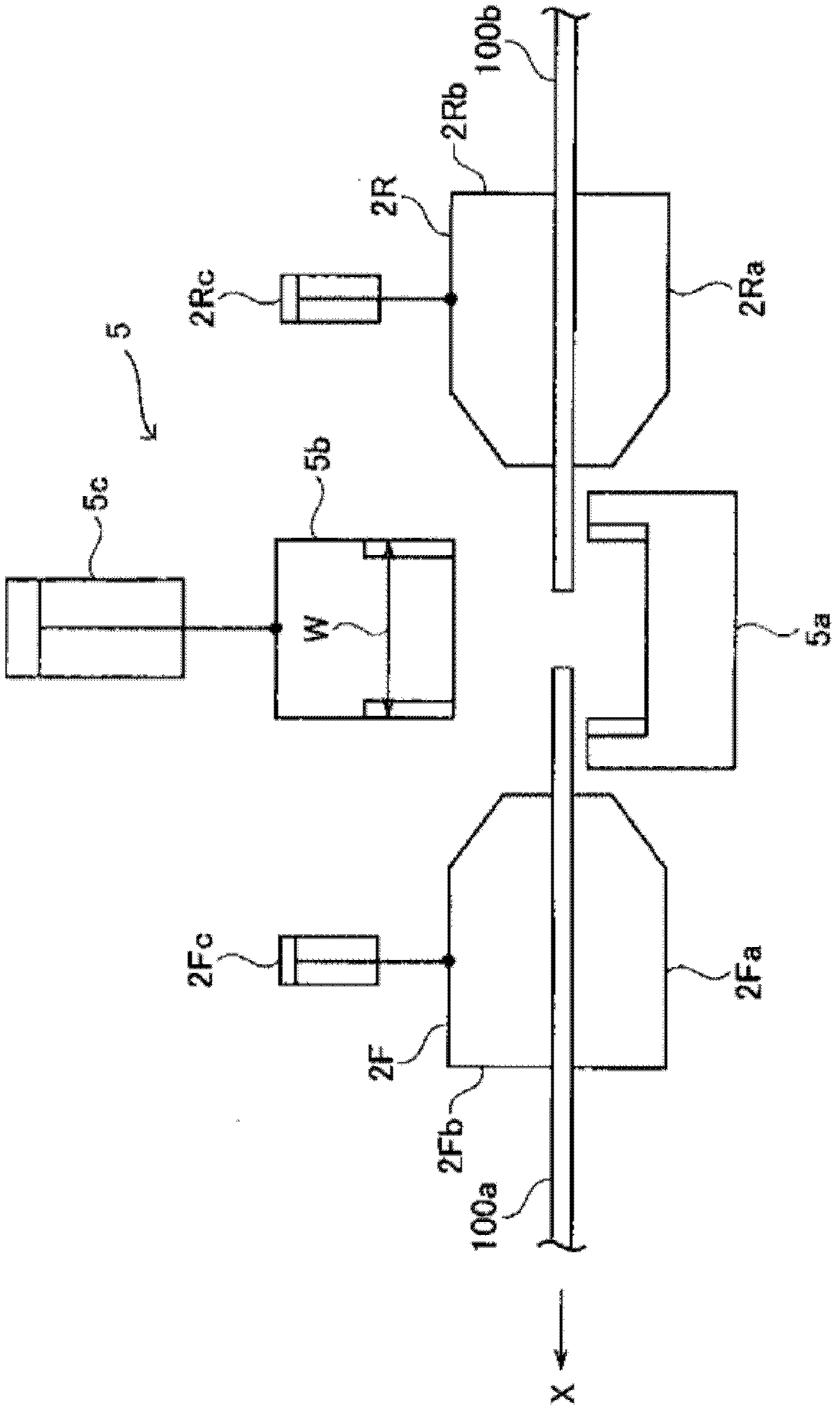

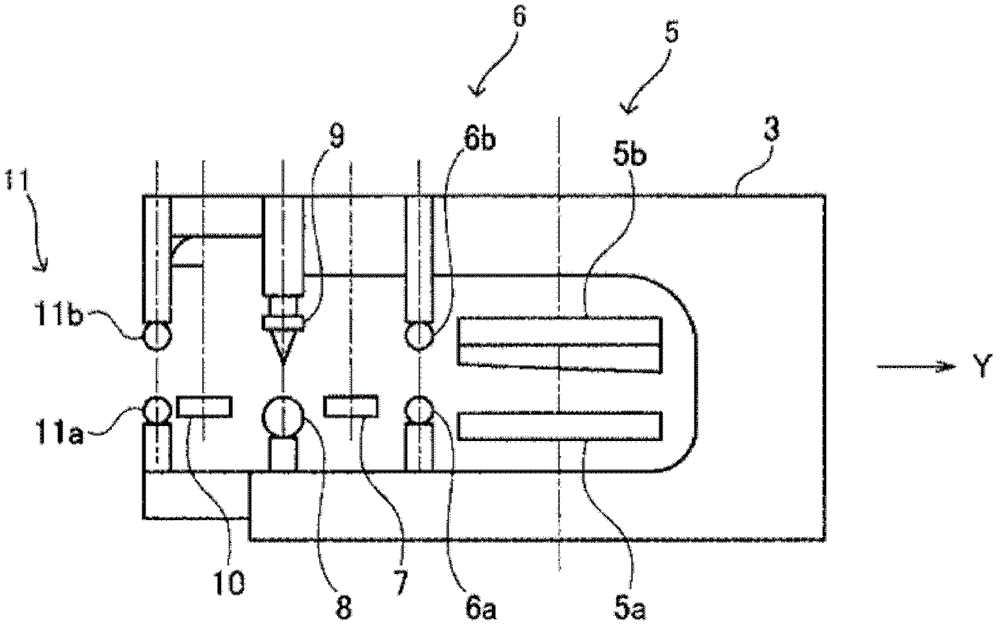

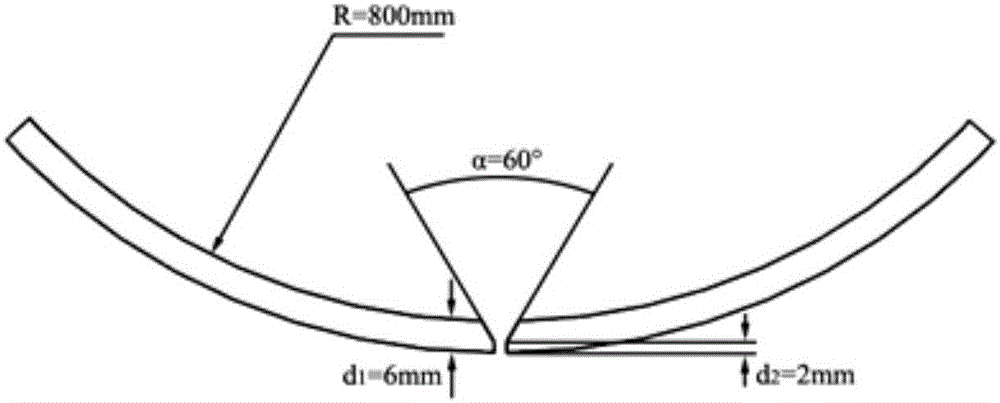

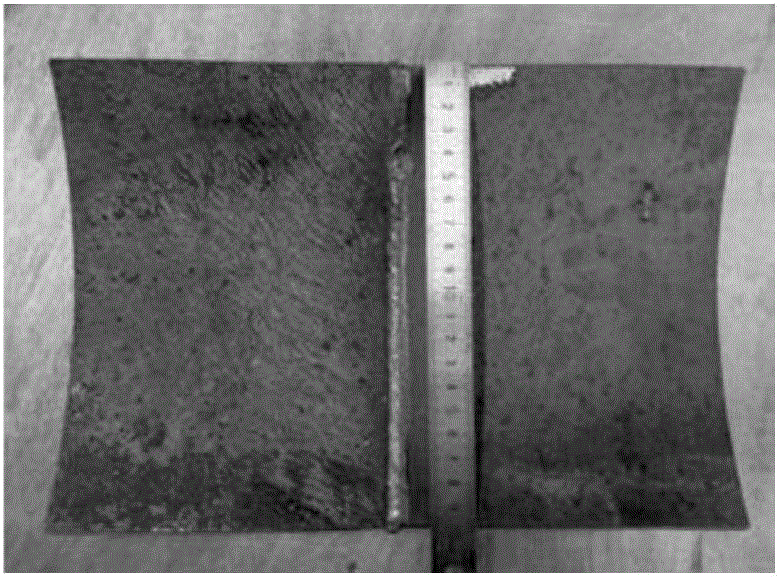

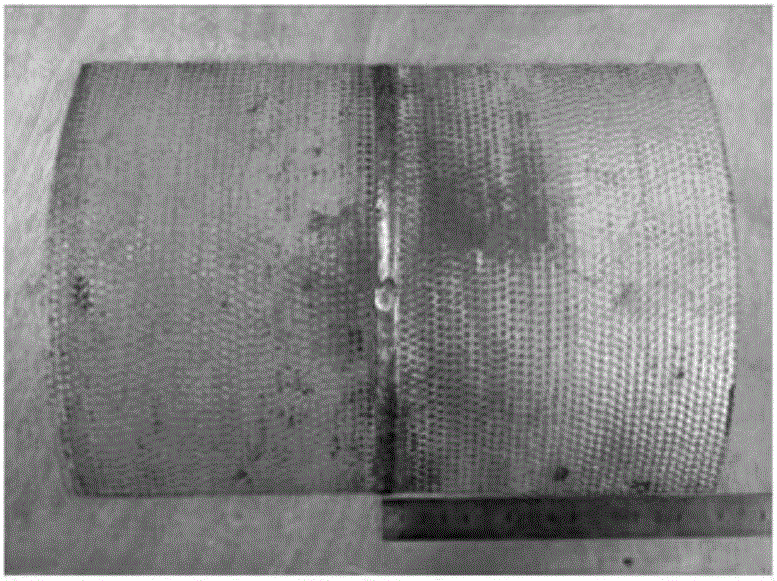

Laser welding method and laser welding device for steel plate

ActiveCN102615428BReduce bad shapeReduce weld crackingWelding/soldering/cutting articlesMetal working apparatusSheet steelLight beam

A method of laser welding for a steel sheet, in which there can be attained reduction of morphological defects of the weld area of welded material and exhibition of satisfactory bonding strength; and a laser welding apparatus therefor. There is provided a method of laser welding for a steel sheet through causing multiple steel sheets to abut on each other at end faces thereof and irradiating the abutted area of the steel sheets brought into mutual abuttal with laser beams to thereby weld the abutted area, comprising the cutting step of cutting end faces of steel sheets into forms suitable for mutual abuttal; the abutting step of bringing the end faces formed by the cutting step into mutual abuttal; the first heating step of heating the abutted area; and the laser welding step of welding by laser the abutted area having been heated by the first heating step.

Owner:NIPPON STEEL CORP +2

Welding method for centrifugal casting ductile iron pipe

ActiveCN106077908AReduce welding stressAvoid Weld CrackingArc welding apparatusShielded metal arc weldingButt joint

The invention discloses a welding method for a centrifugal casting ductile iron pipe. The welding method for the centrifugal casting ductile iron pipe comprises the following steps of (1) using the arc-shaped plate of the ductile iron pipe as a base material, carrying out welding by adopting a butt joint, and forming a straight-Y-shaped groove in the inner side or the outer side of the arc-shaped plate; (2) preheating a welding joint to the temperature from 100 DEG C to 150 DEG C before welding; (3) carrying out welding by adopting CO2 gas shielded welding, continuously welding a first weld joint at the groove of the arc-shaped plate, and welding a weld joint on the back by adopting a backstep welding method; and (4) carrying out heat insulation after welding, and carrying out slow cooling to the room temperature. According to the welding method for the centrifugal casting ductile iron pipe, a novel centrifugal casting ductile iron pipe plate is welded by adopting a CO2 gas shielded welding method under the condition of low temperature preheating, and compared with a traditional shielded metal arc welding method, the welding method provided by the invention has the advantages that the welding technology is simplified, the production cost is reduced, and the welding efficiency is obviously improved.

Owner:STATE GRID SHANDONG ELECTRIC POWER +1

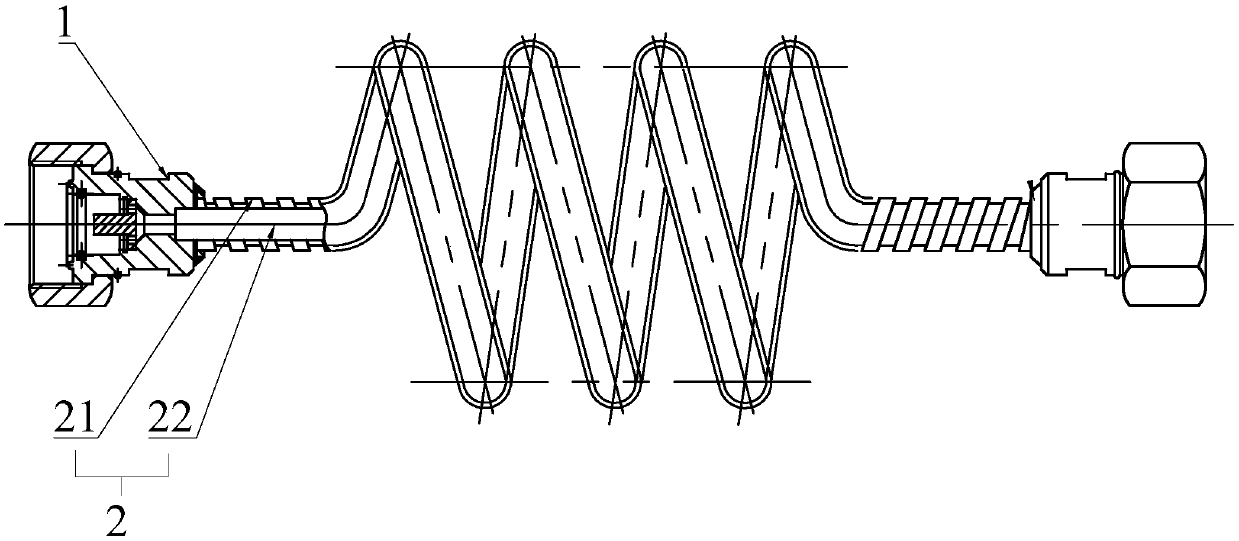

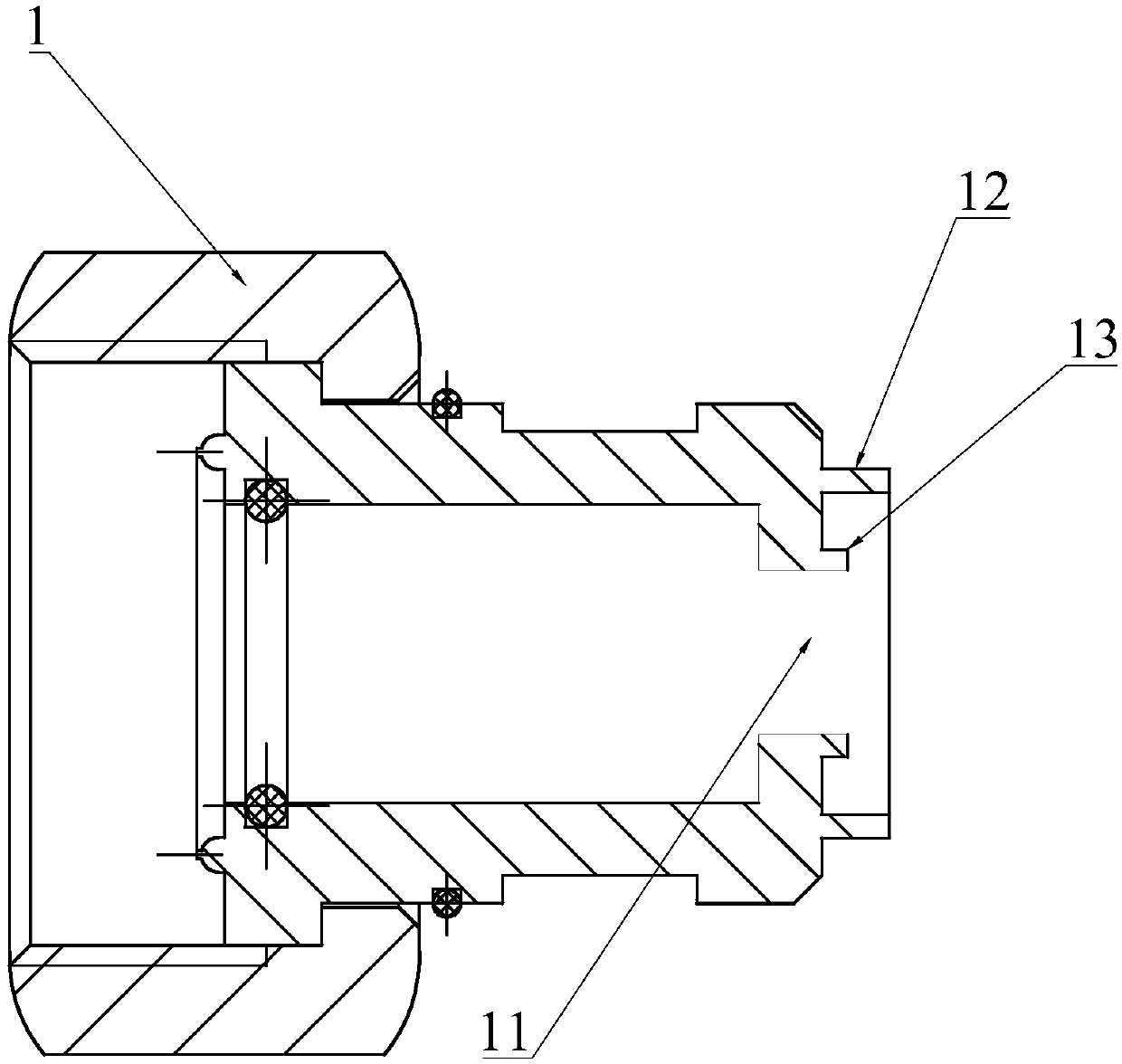

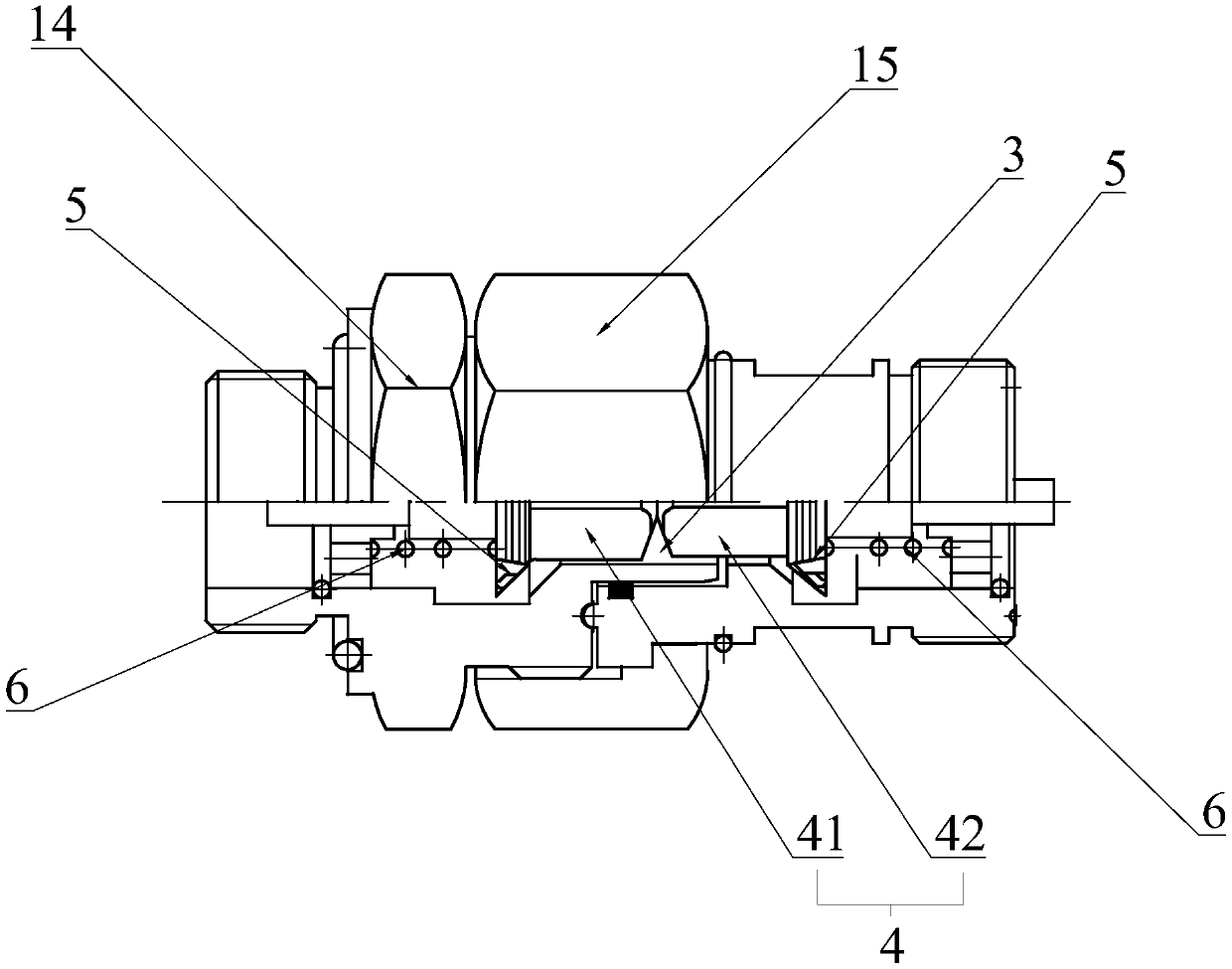

Anti-vibration air pipe module

PendingCN109519643APressure pulsation peak attenuationReduce welding cracksPipe elementsJoints with fluid cut-off meansPeak valueEngineering

The invention discloses an anti-vibration air pipe module. An air way pressure pulse peak value is attenuated to the greatest extent; and the generation length of cracks in the welding link is reduced. The anti-vibration air pipe module is characterized by comprising two joints and a pipe module connected between the two joints; the pipe module comprises an outer hose, and multiple capillary pipesarranged in the outer hose; the joints are provided with step holes; the capillary pipes are arranged in the step holes; first welding flanges for welding the outer hoses are arranged on the end surfaces of the joints; second welding flanges for the capillary pipes are arranged on the edges of the step holes; and the capillary pipes are flexibly connected between the two joints.

Owner:宁波中迪机械有限公司

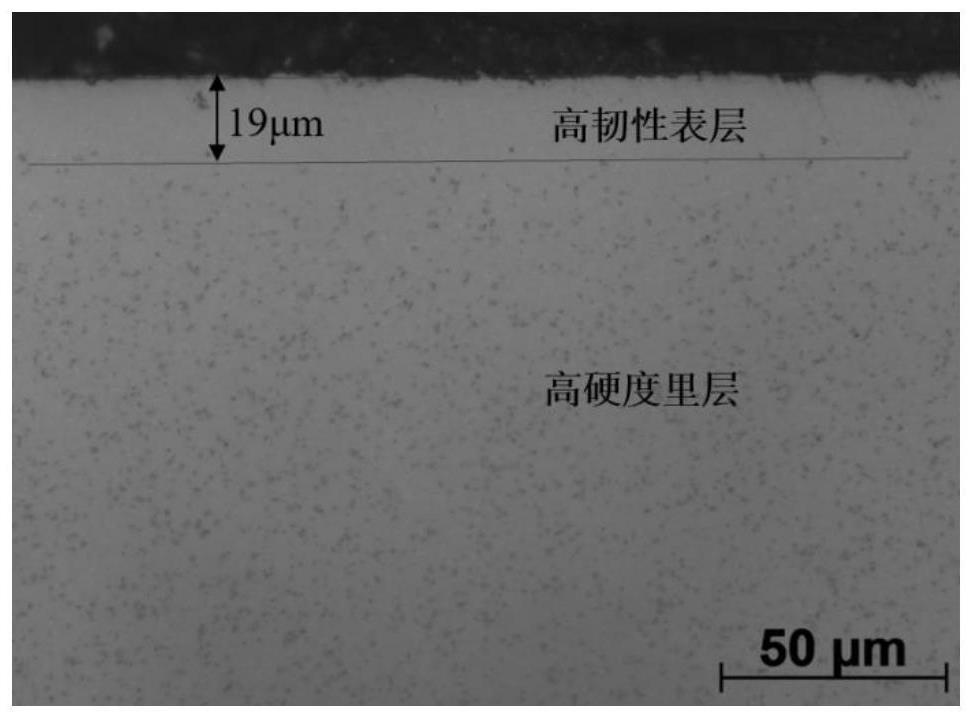

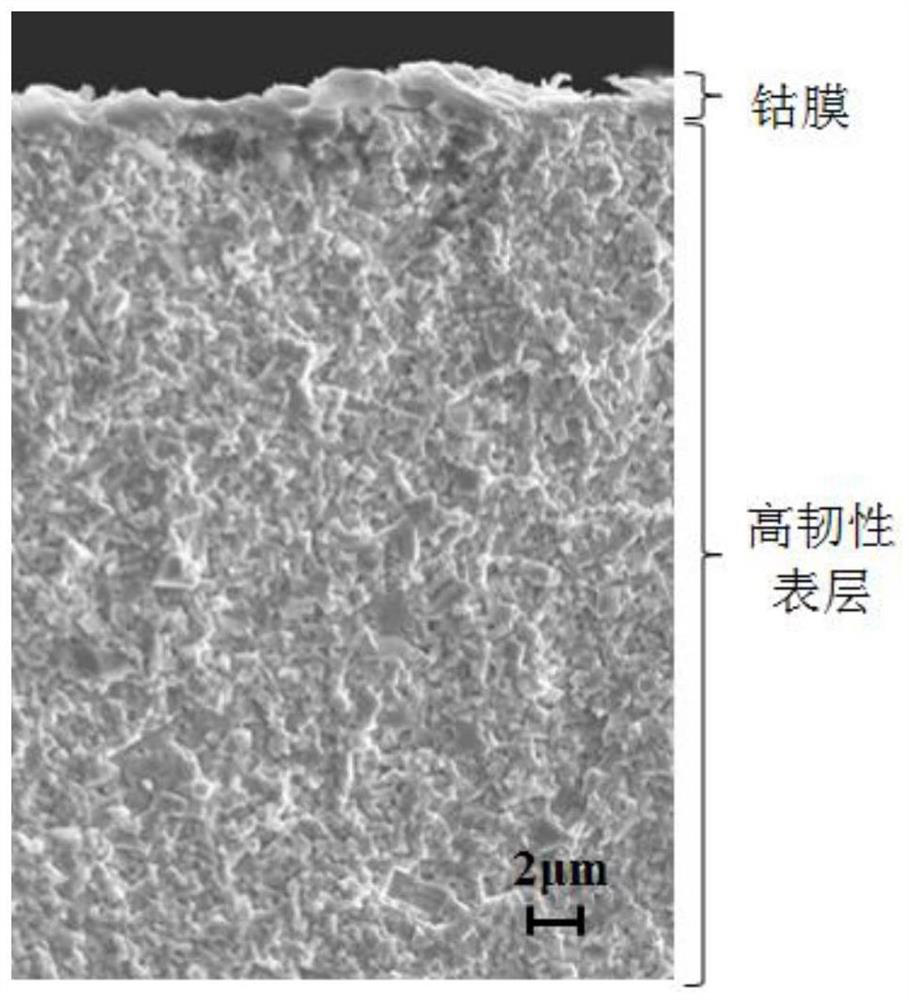

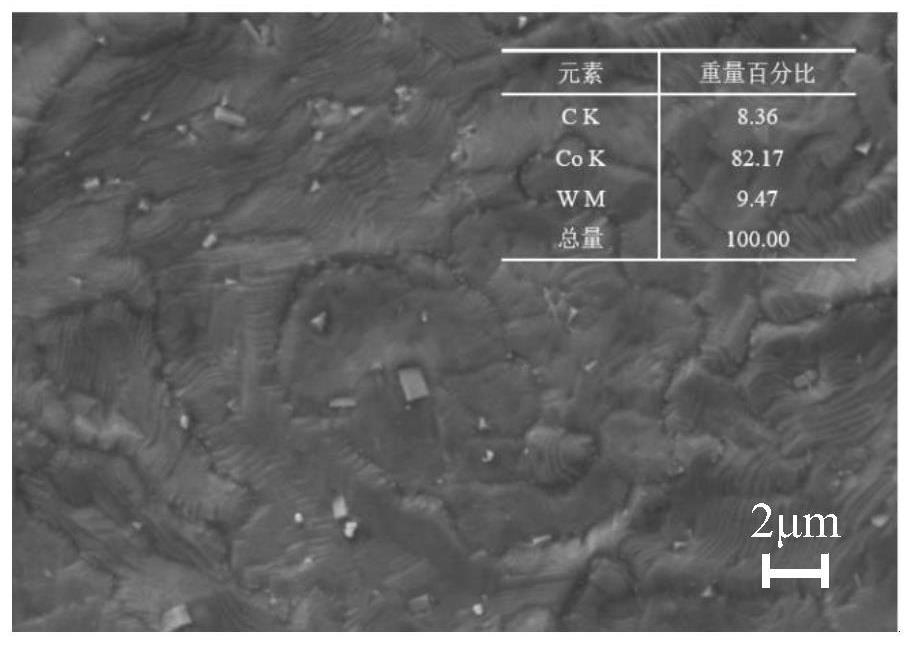

High-hardness hard alloy batten resistant to welding cracking and preparation method of high-hardness hard alloy batten resistant to welding cracking

The invention discloses a high-hardness hard alloy batten resistant to welding cracking and a preparation method thereof.The hard alloy batten is provided with a high-toughness surface layer and a high-hardness inner layer, the binding phase content of the surface layer is 1.2 times or above that of the inner layer, the surface layer is only composed of a WC phase and a binding phase, the thickness of the surface layer is 5-100 microns, and the inner layer is composed of the WC phase, the binding phase and a cubic carbide phase; in addition, the outer surface of the batten is coated with a binding phase, and the thickness of a coating layer is 1-5 microns. The hard alloy batten is prepared from the following components: 80 to 96 weight percent of WC (Wolfram Carbide), 2.0 to 16.5 weight percent of binding phase and 0.5 to 8 weight percent of cubic carbide, wherein the average particle size of the WC is 0.1 to 6 microns. The preparation method comprises the steps of wet grinding, drying, forming, sintering and heat treatment. The batten has excellent welding crack resistance and wear resistance, and has a good application prospect in the field of metal and wood processing.

Owner:九江金鹭硬质合金有限公司

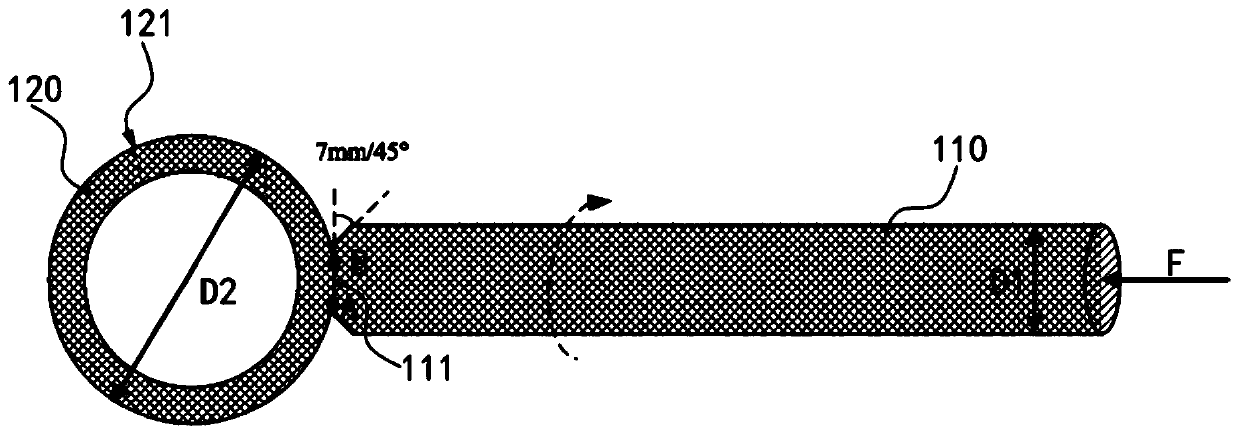

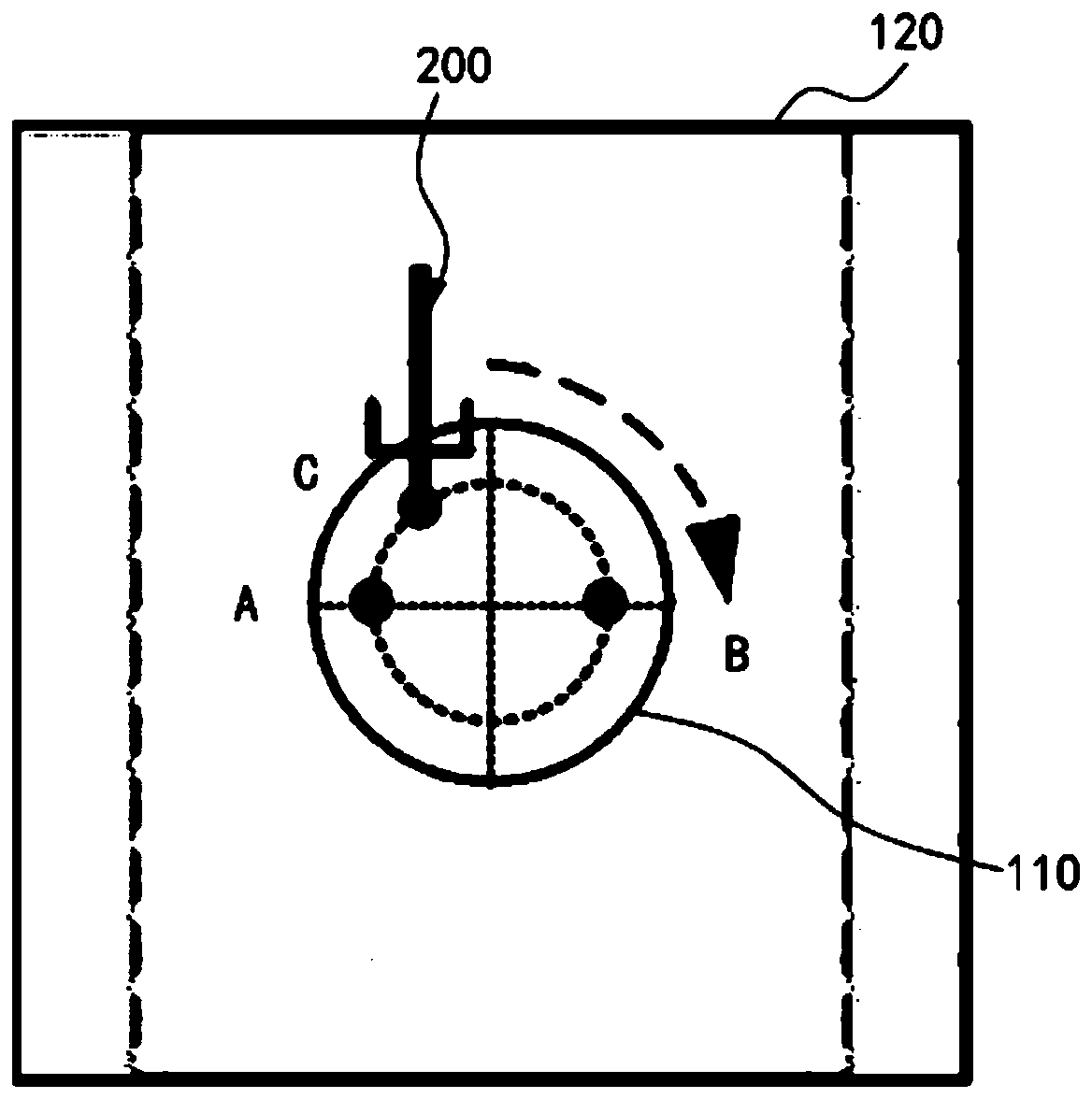

Welding technology

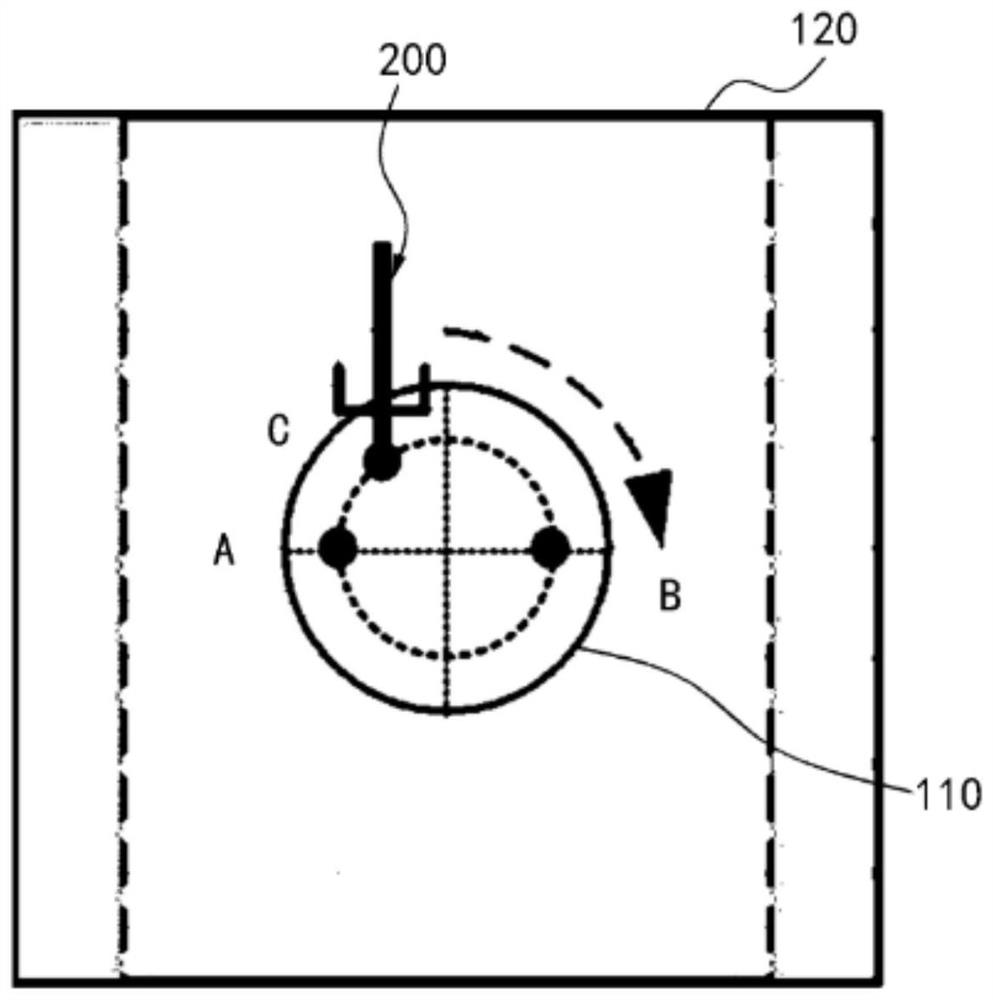

ActiveCN110883404AReduce heat input deficitReduce weld crackingArc welding apparatusFixed positionManufacturing engineering

The invention provides a welding technology. The welding technology comprises the following steps that a first workpiece and a second workpiece are positioned through welding equipment; two maximum clearance points between a circular end face and a cylindrical peripheral face are subjected to weaving welding; an arcing point is selected between the circular end face and the cylindrical peripheralface and corresponds to the position, between the two maximum clearance points, of the corresponding circle circumference of the circular end face; and welding is conducted from the arcing point, meanwhile, the welding equipment is utilized to synchronously and counterclockwise rotate the first workpiece and the second workpiece by taking the center line of the first workpiece as an axis, the welding process comprises two passes of welding, first pass of welding adopts weaving welding, and second pass of welding is conducted immediately without pause after first pass of welding. Through the design, the welding technology utilizes weaving welding to replace fixed position welding in the prior art to weld the maximum clearance points, and defects such as welding cracks and non-fusion causedby insufficient heat input and stress concentration in the welding process can be reduced.

Owner:PANASONIC WELDING SYST TANGSHAN

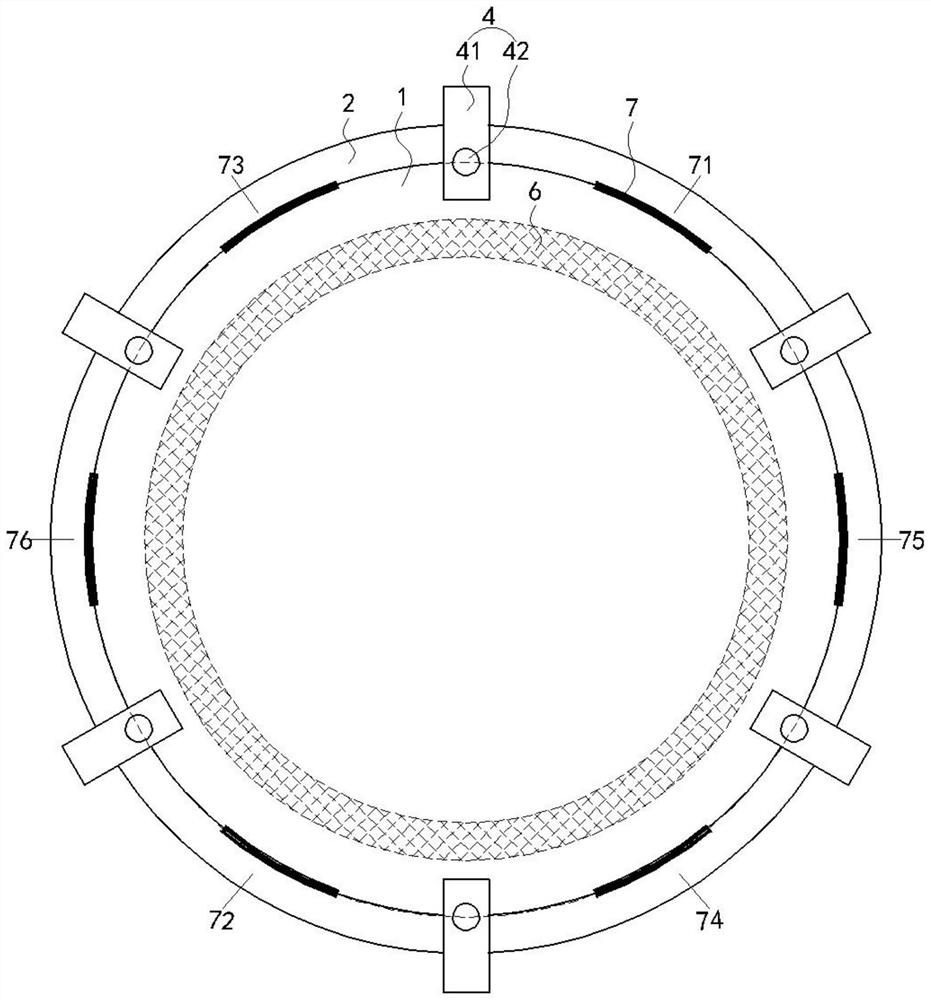

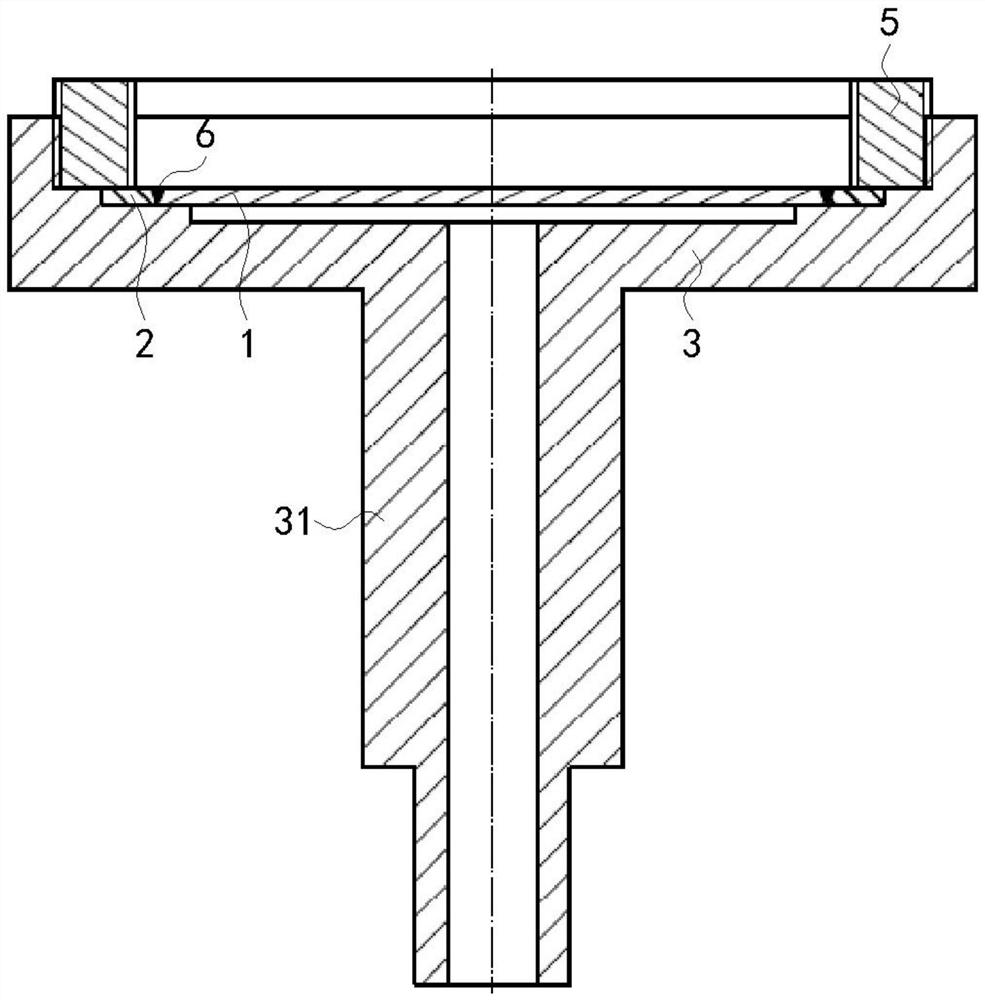

A manufacturing process of manhole well welded parts

The invention relates to the field of welding technologies, and discloses a manufacturing technology for a manhole well welding part. The manufacturing technology for the manhole well welding part comprises the technological steps of steel plate blanking, steel plate rolling, cylinder inner wall reinforcing by adopting an anti-deformation positioning tool, cylinder welding, anti-deformation positioning tool disassembling, flange machining, assembling, total welding and the like, wherein the anti-deformation positioning tool comprises four arc-shaped positioning blocks which jack the inner wallof a cylinder through helical jacking mechanisms and are evenly distributed in the circumferential direction of the inner wall of the cylinder, and the arc-shaped faces of the four arc-shaped positioning blocks make contact with the inner wall of the cylinder. According to the manufacturing technology for the manhole well welding part, welding deformation of the manhole well welding part is reduced, and the manufacturing precision of the manhole well welding part is improved.

Owner:JIANGYIN FUREN HIGH TECH

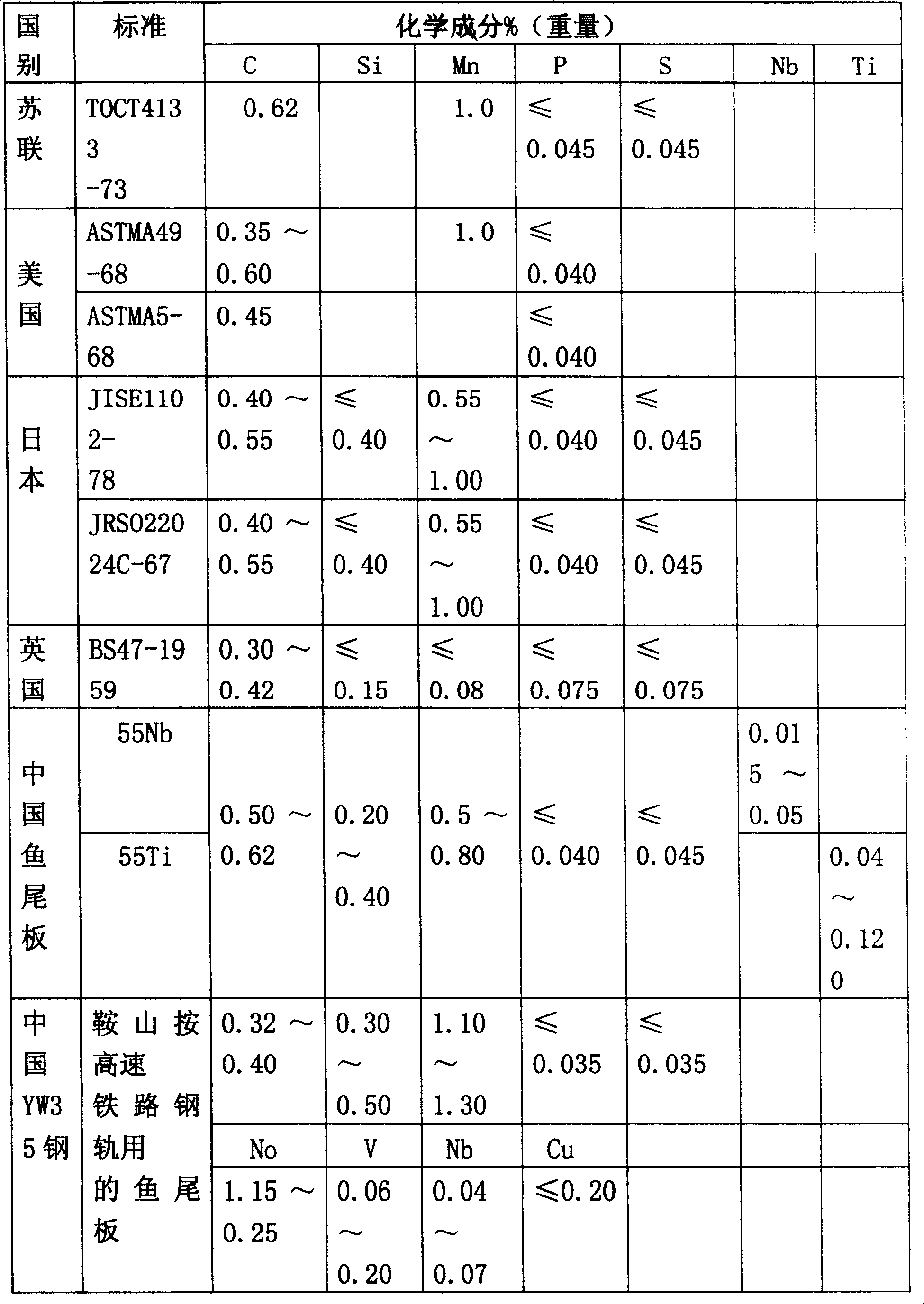

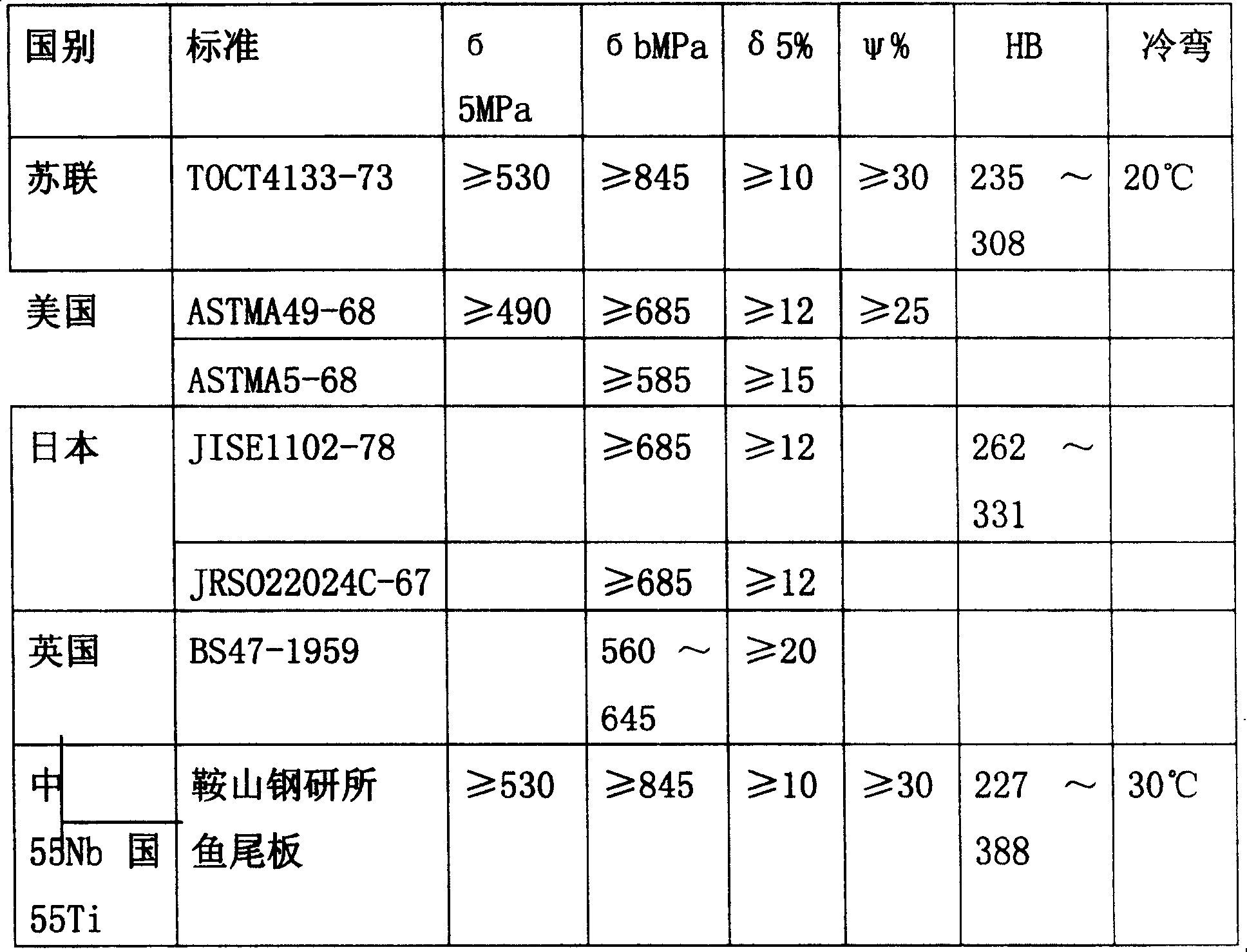

Welding method for thick-wall alloy pipeline of needle coke device

The invention discloses a welding method for a thick-wall alloy pipeline of a needle coke device. The alloy pipeline is made of a 1Cr5Mo material. The welding method comprises the following steps of material selection, groove preparation and joint pairing, preheating before welding, multi-layer and multi-pass welding and heat treatment. According to the welding method, through proper material selection, preparation of a welding groove and multi-layer and multi-pass welding, welding heat input can be reduced, and welding line energy is controlled; in addition, through heat treatment of a rear-layer welding pass on a front layer, grains can be refined, and the comprehensive performance of a welding joint is improved; and during heat treatment after welding, preheating treatment is conducted firstly, austenite is completely converted into martensite, then tempering heat treatment is conducted, the hardness of all areas of the joint can be reduced, the toughness, the deformation capacity and the high-temperature endurance strength of the joint are improved, the internal stress of the joint is eliminated, and welding cracks are greatly reduced.

Owner:CHINA NAT CHEM ENG NO 14 CONSTR

Quasi bainitic steel

InactiveCN100408712CImprove mechanical propertiesImprove strength and toughnessConstruction materialRail switchesElectric arc furnaceMolten steel

A quasi-bainite steel with high strength, gouthness, weldability and antiwear performance for railway contains C (0.10-0.25 wt.%), Si (0.80-2.60), Mn (1.0-3.5), Mn (0.2-0.8), Cr (0.3-2.0), Ni (0.50-1.5), Nb (0.01-0.07), V (0.10-0.70) and Fe (rest). Its preparing process features that the electric furnace or converter is used for smelting while the contents of N2, H2 and O2 in molten steel are controlled.

Owner:河南省强力机械有限公司

A kind of 7000 series alloy material for automobile bumper and its production method

The invention discloses a 7, 000-series alloy material for automobile bumpers. The 7, 000-series alloy material for the automobile bumpers is characterized in that the aluminum alloy comprises the alloy ingredients of Zn, Mg, Cu, Zr, Ti, Sn, Mn, Ag, Co, Sc, Yb, B, Cr4 and the balance aluminum and unavoidable impurities, wherein the ratio of Mg to Zn ranges from 0.17 to 0.19, the ratio of Cu to Mgranges from 0.43 to 0.53, the ratio of Cu to Ti ranges from 1.5 to 1.8, the content of one single impurity is smaller than or equal to 0.005%, the total content of the impurities is smaller than or equal to 0.1%, the average grain diameter of aluminum alloy grains ranges from 20 microns to 40 microns. When the alloy is observed through SEM and TEM, the area percentage of the strengthening phase MgZn2 ranges from 1% to 1.6% while the average size of the MgZn2 ranges from 50 nanometers to 60 nanometers, the area percentage of the strengthening phase Mg2Sn ranges from 0.3% to 0.6% while the average size of the Mg2Sn ranges from 30 nanometers to 50 nanometers, the area percentage of the strengthening phase Al6Mn ranges from 0.3% to 0.4% while the average size of the Al6Mn ranges from 20 nanometers to 30 nanometers, the area percentage of the strengthening phase Al3Ti ranges from 0.5% to 0.8% while the average size of the Al3Ti ranges from 20 nanometers to 30 nanometers, the yield strengthranges from 580 MPa to 650 Mpa, the tensile strength ranges from 670 MPa to 720 MPa, and the elongation ranges from 18% to 23%.

Owner:温州市赢创新材料技术有限公司

A Welding Method of Large Size Thin Wall Beryllium Sheet and Aluminum Alloy Ring

ActiveCN111215741BAvoid welding deformationGuarantee welding qualityElectron beam welding apparatusWelding deformationMaterials science

The invention discloses a method for welding a large-size thin-walled beryllium piece and an aluminum alloy ring, and belongs to the technical field of welding methods for beryllium pieces and aluminum alloy rings. The method for welding the large-size thin-walled beryllium piece and the aluminum alloy ring includes the following steps that positioned welding clamping is carried out, the berylliumpiece is nested in the aluminum alloy ring in a fit manner, and the beryllium piece and the aluminum alloy ring are clamped on a rotary table by positioning pincers; positioned welding is carried out, symmetrical positioned welding is conducted on the beryllium piece and the aluminum alloy ring by vacuum electron beam welding to form a positioned welding assembly; full weld clamping is carried out, the positioning pincers are disassembled, and the aluminum alloy ring of the positioned welding assembly is clamped on the rotary table by a positioning ring; and full welding is carried out, fullwelding is conducted on the beryllium piece and the aluminum alloy ring by vacuum electron beam welding to form a full welding assembly. Welding deformation of the beryllium piece and the aluminum alloy ring in the welding process can be restrained, welding cracks are not prone to occurring, and the obtained welded joint can also meet use requirements of high environment temperatures and other harsh environments.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

welding process

The invention proposes a welding process, which includes the following steps: using welding equipment to locate the first workpiece and the second workpiece; using swing welding at the two largest gap points between the circular end surface and the cylindrical peripheral surface; Select an arc starting point between the cylindrical peripheral surfaces, and the arc starting point corresponds to the position between the two maximum gap points on the corresponding circle of the circular end surface; the arc starting point is used for welding, and the welding equipment is used at the same time. The center line of the workpiece is the shaft synchronously rotating the first workpiece and the second workpiece counterclockwise. The welding process includes two weldings. The first welding adopts swing welding, and the second welding is performed immediately after the first welding. Through the above design, the present invention uses swing welding to replace the fixed position welding in the existing technology to weld the largest gap point, which can reduce welding cracks and lack of fusion caused by insufficient heat input and stress concentration during the welding process.

Owner:PANASONIC WELDING SYST TANGSHAN

A method for protecting and repairing the furnace skin after the cooling wall of the blast furnace is burned

ActiveCN109306387BImprove cooling effectReduce weld crackingCooling devicesCooling effectStructural engineering

Owner:BAOSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com