Method for welding large-size thin-walled beryllium piece and aluminum alloy ring

A welding method and technology of aluminum alloy, applied in welding equipment, electron beam welding equipment, metal processing equipment, etc., can solve the problem of large penetration of welded joints, complicated pre-welding treatment process, and not suitable for large-sized thin-walled beryllium sheets and Aluminum alloy ring group welding and other problems, to achieve the effect of reducing welding deformation and reducing welding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] In Example 1, the specification of the beryllium sheet 1 is Φ90mm×1.2mm, the inner diameter of the aluminum alloy ring 2 is Φ90mm, and the ring width is 4mm.

[0055] A kind of welding method of large-scale thin-walled beryllium sheet and aluminum alloy ring of embodiment 1, comprises the following steps:

[0056] S1. Cleaning steps: use pickling and acetone / alcohol scrubbing to clean the parts to be assembled and welded between the beryllium sheet 1 and the aluminum alloy ring 2 to make the surface clean;

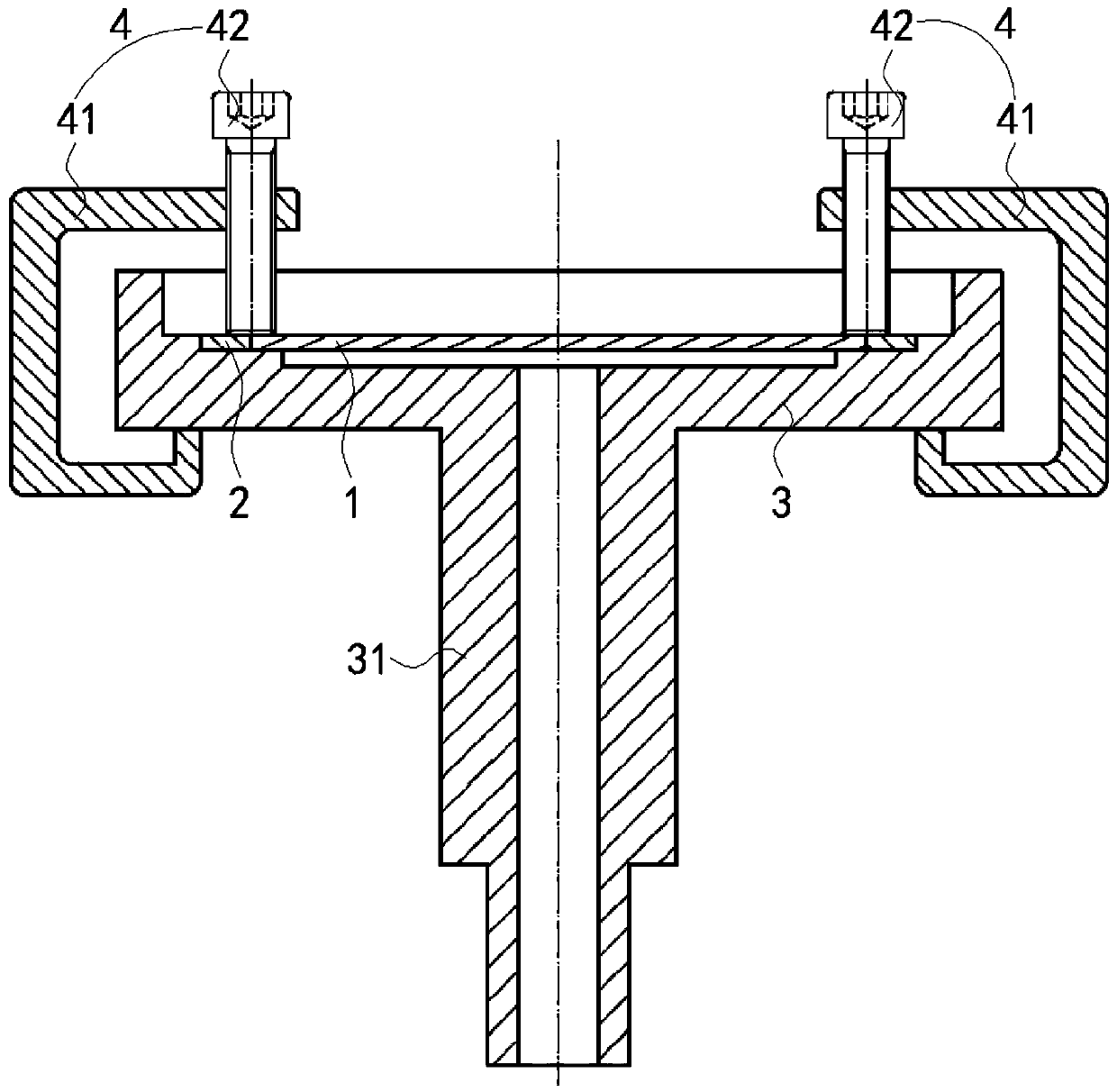

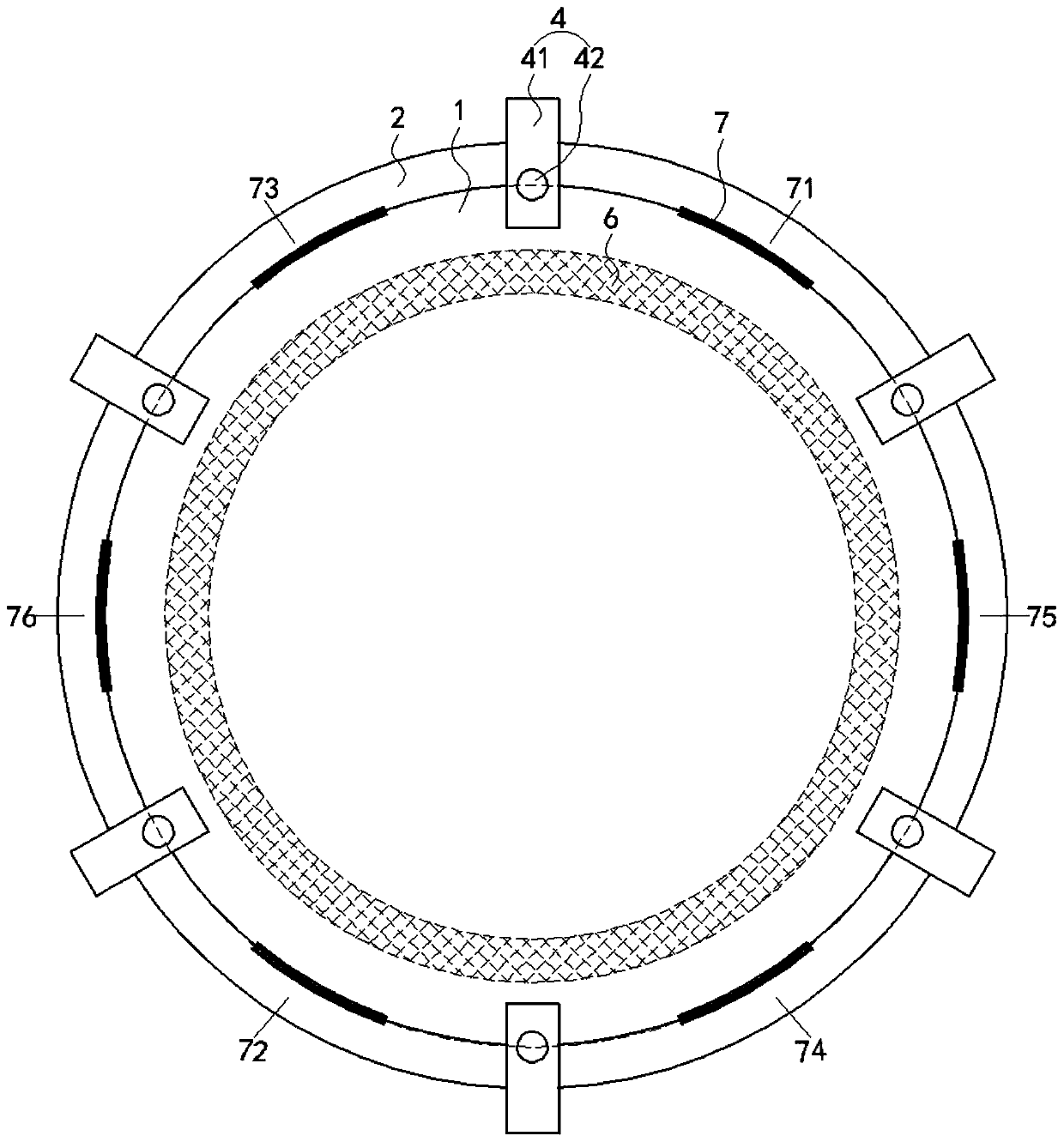

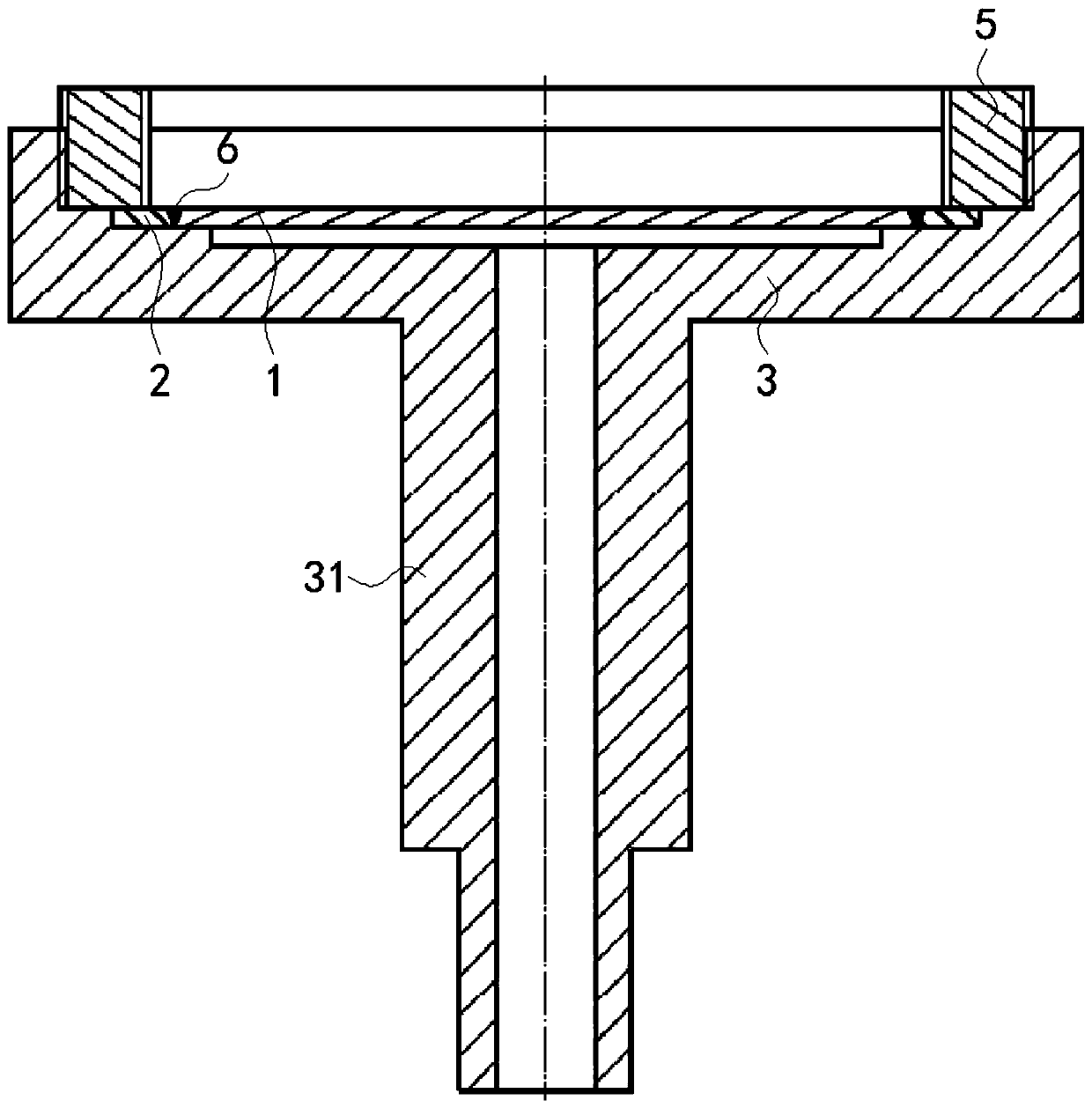

[0057] S2. Tack welding and clamping steps: Nest the beryllium sheet 1 in the aluminum alloy ring 2, and the beryllium sheet 1 and the aluminum alloy ring 2 are fitted together, and the beryllium sheet and the aluminum alloy ring are fixed and clamped by using positioning pliers 4 On the turntable 3, there are four positioning tongs 4, which are distributed in a circular array;

[0058] S3, tack welding preheating step: preheat the beryllium sheet 1 by vacuum elect...

Embodiment 2

[0065] In Example 2, the specification of the beryllium sheet 1 is Φ180mm×1.4mm, the inner diameter of the aluminum alloy ring 2 is Φ180mm, and the ring width is 4.5mm.

[0066] The welding method of a kind of large-scale thin-walled beryllium sheet and aluminum alloy ring of embodiment 2 comprises the following steps:

[0067] S1. Cleaning steps: use pickling and acetone / alcohol scrubbing to clean the parts to be assembled and welded between the beryllium sheet 1 and the aluminum alloy ring 2 to make the surface clean;

[0068] S2. Tack welding and clamping steps: Nest the beryllium sheet 1 in the aluminum alloy ring 2, and the beryllium sheet 1 and the aluminum alloy ring 2 are fitted together, and the beryllium sheet and the aluminum alloy ring are fixed and clamped by using positioning pliers 4 On the turntable 3, there are six positioning tongs 4, which are distributed in a circular array;

[0069] S3, tack welding preheating step: preheat the beryllium sheet 1 by vacuum...

Embodiment 3

[0076] In Example 3, the specification of the beryllium sheet 1 is Φ200mm×1.5mm, the inner diameter of the aluminum alloy ring 2 is Φ200mm, and the ring width is 5mm.

[0077] A kind of welding method of large-scale thin-walled beryllium sheet and aluminum alloy ring of embodiment 3 comprises the following steps:

[0078] S1. Cleaning steps: use pickling and acetone / alcohol scrubbing to clean the parts to be assembled and welded between the beryllium sheet 1 and the aluminum alloy ring 2 to make the surface clean;

[0079] S2. Tack welding and clamping steps: Nest the beryllium sheet 1 in the aluminum alloy ring 2, and the beryllium sheet 1 and the aluminum alloy ring 2 are fitted together, and the beryllium sheet and the aluminum alloy ring are fixed and clamped by using positioning pliers 4 On the turntable 3, there are six positioning tongs 4, which are distributed in a circular array;

[0080] S3, tack welding preheating step: preheat the beryllium sheet 1 by means of vac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com